Pipes Automatic Storage Warehouse

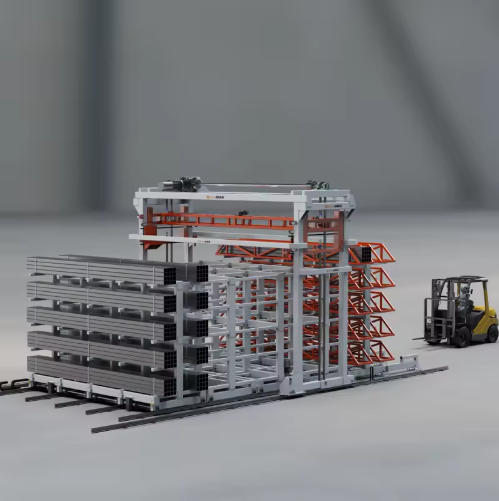

The Herochu Automated Warehouse is a fully integrated system comprising a robust loading and unloading gantry, high-capacity profile material racks, dedicated material frames, and precision-engineered guide rails. The core structure is fabricated from high-tensile steel, providing exceptional load-bearing capacity and enduring durability. It is designed to securely store a diverse range of materials, from single, sensitive pipes to bundled profiles of varying types and weights.

Revolutionize Industrial Storage: The Herochu Automated Pipes Storage Warehouse

For executives and plant managers in metal fabrication, construction, and large-scale manufacturing, the storage and retrieval of long goods—pipes, tubes, bars, and structural profiles—represents a persistent and costly challenge. Traditional methods involving cantilever racks, forklifts, and overhead cranes are not only inefficient but also fraught with operational risks, including high labor costs, significant floor space consumption, and elevated safety hazards. These conventional systems create bottlenecks that stifle productivity and impede scalability. The Herochu Pipes Automatic Storage Warehouse is engineered to dismantle these limitations, introducing a new era of intelligent, high-density, and fully automated logistics for long goods management. This is not merely a storage system; it is a transformative operational asset, customizable to your specific workshop requirements and starting at a competitive $42,000.

As a cornerstone of modern industrial infrastructure, the Herochu automated warehouse is designed and certified to the most rigorous international standards, bearing the CE, EU, and ISO 9001 marks of quality and safety. This certification guarantees that every component, from the structural framework to the drive mechanisms, meets unparalleled benchmarks for performance, durability, and operational security. This system represents a significant capital investment that is meticulously justified through rapid returns in efficiency, space savings, and personnel allocation.

Engineered for Uncompromising Performance and Customization

The Herochu Automated Warehouse is a fully integrated system comprising a robust loading and unloading gantry, high-capacity profile material racks, dedicated material frames, and precision-engineered guide rails. The core structure is fabricated from high-tensile steel, providing exceptional load-bearing capacity and enduring durability. It is designed to securely store a diverse range of materials, from single, sensitive pipes to bundled profiles of varying types and weights.

True to its promise of adaptability, the system’s physical dimensions are tailored to your facility’s constraints and opportunities. The number of vertical layers (typically from 8 to 13) and the overall quantity of storage positions are customized according to your factory’s height and spatial layout, ensuring optimal use of your cubic volume. The system is available in standard widths to accommodate most common profile lengths, including 6015mm, 6020mm, and 6025mm options. Each storage layer is engineered to support substantial weight, with load ratings of 3T or 5T per level, ensuring robust performance even under continuous industrial demand.

Movement within the warehouse is governed by a supremely reliable and precise drive system. The gantry operates on a foundation of linear guide rails for smooth, accurate traversal, coupled with a heavy-duty chain drive transmission system that ensures positive movement and positioning. This mechanical combination delivers consistent and efficient operation, with a vertical lifting speed of 9 meters per minute and an inlet/outlet speed of 12 meters per minute, facilitating a rapid and seamless material flow.

The Tangible Advantages of Automation: Beyond Mere Storage

Implementing the Herochu Pipes Automatic Storage Warehouse delivers a comprehensive strategic advantage across every facet of your operation:

-

Unprecedented Efficiency Gains: The system fundamentally optimizes material flow. By automating the handling process, it eliminates the time-consuming search and retrieval tasks associated with manual systems. Materials are delivered automatically to a comfortable, ergonomic working height, ready for further processing or dispatch, slashing waiting times and accelerating throughput.

-

Radical Space Optimization: This automated system makes superior use of available area. By eliminating the wide aisles required for forklift and crane operation, it transforms your storage footprint. The high-density, vertical design allows you to store a vastly greater volume of long goods within the same, or even a reduced, floor space, effectively increasing your facility’s capacity without expansion.

-

Flawless Inventory Accuracy and Management: Human error in stock management is rendered obsolete. The integrated Warehouse Management System (WMS) provides real-time, precise monitoring and tracking of all inventory. Every item is digitally logged upon entry; stock levels are automatically updated upon retrieval, and even partially used or shortened items can be booked back into the system. This results in the virtual elimination of stock shortages, misplaced materials, and costly production delays.

-

Enhanced Workplace Safety: Automation dramatically reduces the need for manual handling of heavy, bulky, and often awkward long goods. By minimizing direct employee interaction with forklifts and cranes for storage tasks, the system significantly mitigates the risk of workplace accidents, product damage, and associated liability, fostering a safer and more secure working environment.

-

Strategic Labor Reallocation and Cost Reduction: While the initial investment is substantive, the total cost of ownership is markedly lower. The system liberates skilled workers from mundane, physically demanding tasks, allowing for their redeployment to higher-value areas of production where their expertise is more critically needed. This not only improves job satisfaction but also helps alleviate the pressures of skilled labor shortages.

The Herochu Pipes Automatic Storage Warehouse is more than equipment; it is a strategic decision to embrace Industry 4.0 principles. It provides the data, flexibility, and control necessary to build a more resilient, responsive, and profitable operation. We invite you to contact our engineering team to schedule a consultation and explore a fully customized solution designed to meet your precise operational and spatial requirements.

Q1: What steps should I take to start the procurement process?

Q2: How can I inform you of my need for suitable shelves?

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

Q4: Do you offer on-site installation and debugging services?

Q5: What measures do you take to ensure product quality?

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Q7: How can I verify your company’s strength?

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

PRODUCTS

-

Heavy Duty Cantilever Racking System

Pipe Store Long Span Goods Automated Storage System

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Manual Control Roll out Sheet Metal Rack with Forklift

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Pull Out Sheet Storage Drawer Rack Roll-Out Sheet Rack for Sheets

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Customizable Workshop Storage Cantilever Racking System

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Loading/unloading System for Fiber Laser Cutting Machine

Read moreRated 0 out of 5