Sheet Metal Storage for 60×120 Steel Sheets

Herochu specializes in resolving these critical operational bottlenecks through the application of professionally engineered storage systems. We recognize that effective storage transcends mere organization; it is an integral component of a streamlined, safe, and profitable production workflow. Proper storage methodology delivers tangible benefits across the entire operation. It first and foremost protects the material investment by securely cradling sheets to prevent warping under their own weight, shielding finished surfaces from scratches, and allowing for air circulation that mitigates corrosion. Furthermore, a purpose-designed system dramatically improves spatial economics by leveraging vertical cube storage, effectively freeing up valuable and expensive floor space for active production rather than passive storage. This vertical organization subsequently boosts operational efficiency by making sheet retrieval a faster, more predictable, and logical process, eliminating time-consuming searches and difficult extraction from stacked piles. Ultimately, the most significant benefit is the enhancement of workplace safety, systematically reducing the inherent risks associated with manual handling and movement of heavy, sharp-edged materials.

Optimizing Industrial Storage: A Specialist Guide to 60×120 Inch Sheet Metal Racking Solutions by Herochu

The 60×120 inch sheet metal panel represents a fundamental building block for countless industrial and manufacturing processes. This specific dimension, equivalent to 1525x3050mm, offers significant advantages in material yield and cutting efficiency for sectors ranging from HVAC ductwork fabrication and automotive component production to structural construction and custom machinery manufacturing. However, the very size that makes these sheets so efficient on the production floor presents a formidable logistical challenge within the warehouse or workshop. The manual handling of such large, heavy, and often delicate materials is fraught with risk, including potential for severe worker injury, product damage through bending or scratching, and profound inefficiencies in space utilization. Standard storage methods frequently prove inadequate, leading to cluttered workspaces, dangerous retrieval processes, and damaged inventory.

Herochu specializes in resolving these critical operational bottlenecks through the application of professionally engineered storage systems. We recognize that effective storage transcends mere organization; it is an integral component of a streamlined, safe, and profitable production workflow. Proper storage methodology delivers tangible benefits across the entire operation. It first and foremost protects the material investment by securely cradling sheets to prevent warping under their own weight, shielding finished surfaces from scratches, and allowing for air circulation that mitigates corrosion. Furthermore, a purpose-designed system dramatically improves spatial economics by leveraging vertical cube storage, effectively freeing up valuable and expensive floor space for active production rather than passive storage. This vertical organization subsequently boosts operational efficiency by making sheet retrieval a faster, more predictable, and logical process, eliminating time-consuming searches and difficult extraction from stacked piles. Ultimately, the most significant benefit is the enhancement of workplace safety, systematically reducing the inherent risks associated with manual handling and movement of heavy, sharp-edged materials.

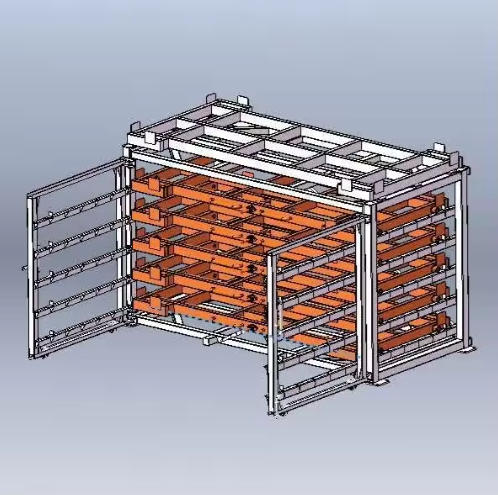

To address the specific challenges of the 60×120 inch format, Herochu has developed a range of racking solutions, each tailored to distinct operational volumes and access requirements. Our Forklift Sheet Metal Rack is engineered for high-volume storage environments where full pallets are the standard unit of movement. Designed with a stable, heavy-duty structure and custom-sized to the exact 3050mm sheet length, this system facilitates safe and effortless loading and unloading via forklift, making it the ideal solution for bulk raw material inventory. For workshops requiring frequent access to individual sheets, our Roll-Out Sheet Metal Rack offers a superior alternative. This system features individual drawers that glide out on heavy-duty bearings, allowing operators to select a single sheet without disturbing the entire stack. This not only minimizes handling damage but also provides easy manual access, making it perfect for daily production needs where sheet variety is common.

Understanding that many facilities operate with a hybrid storage model, we offer a combination system that integrates the best of both worlds. The Hybrid Sheet Metal Rack strategically places roll-out drawers in the lower section for high-frequency access, while the upper section is configured for bulk, forklift-accessible pallet storage. This innovative design maximizes vertical space utilization and is perfectly suited for facilities that need to manage both active project materials and bulk inventory within the same footprint. For operations where efficiency, space, and inventory management are paramount, our Automated Sheet Metal Storage System represents the pinnacle of storage technology. This fully automated vertical tower system is designed for large-format sheets and is controlled via an intuitive touchscreen interface. It delivers unparalleled gains by drastically reducing labor requirements, enhancing safety by removing manual interaction, and minimizing the facility’s spatial footprint through ultra-high-density storage. This solution is a strategic investment for forward-thinking factories targeting high levels of automation and data-driven inventory control.

A core tenet of the Herochu philosophy is that no two workshops are identical. Off-the-shelf solutions often create new problems while solving others. Therefore, we specialize in fully custom-engineered storage systems. Our engineering team engages in a consultative process to deliver solutions that may include specific load capacity adjustments to match your material density, anti-slip surface treatments on rails and supports to prevent sheet movement, and a variety of protective surface finish options to ensure longevity in harsh industrial environments. We provide comprehensive support, from initial rack layout planning that optimizes workflow to professional installation services, ensuring seamless integration into your existing operation.

As an internationally recognized manufacturer, Herochu’s commitment to quality and safety is certified by CE, EU, and ISO 9001 standards. These certifications guarantee that every product leaving our facility meets the highest benchmarks for structural integrity, user safety, and manufacturing excellence. We invite you to transform the way you handle 60×120 inch sheet metal. By partnering with Herochu, you are investing in a system that enhances protection for your materials, optimizes your valuable workspace, accelerates operational efficiency, and fundamentally safeguards your personnel. Our customizable solutions are designed to provide a definitive return on investment, with configurations available to meet specific requirements starting at $3,660. Contact our technical sales team today for a detailed consultation and to explore how a tailored Herochu storage system can become a cornerstone of your facility’s productivity and safety.

Q1: What steps should I take to start the procurement process?

Q2: How can I inform you of my need for suitable shelves?

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

Q4: Do you offer on-site installation and debugging services?

Q5: What measures do you take to ensure product quality?

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Q7: How can I verify your company’s strength?

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

PRODUCTS

-

Heavy Duty Cantilever Racking System

Heavy Duty Telescopic Cantilever Storage System Metal Pipe Storage System Shelves

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Automatic Steel Plate Storage Racking System

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Automatic Pallet Racking System Solution Steel Shelf Metal Rack

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Pipe Store Long Span Goods Automated Storage System

Read moreRated 0 out of 5