Revolutionizing Industrial Logistics: The High-Density Forklift Cassette Racking System for Optimal Sheet Metal Storage

In the realm of industrial manufacturing and metal fabrication, the efficiency of production is fundamentally governed by the effectiveness of material logistics. The storage and handling of raw sheet materials represent a critical juncture in the operational workflow, one where inefficiencies can propagate delays, increase costs, and elevate safety risks throughout the entire production chain. Traditional storage methodologies, including standard shelving, A-frames, or floor stacking, are increasingly recognized as inadequate for modern high-output facilities. These conventional approaches consume a prohibitive amount of valuable floor space, create organizational disarray that slows down material retrieval, and impose significant hazards associated with the manual handling of heavy, sharp-edged sheets. The necessity for a sophisticated, integrated storage solution is not merely a matter of organization but a strategic imperative for enhancing productivity, safety, and spatial economics.

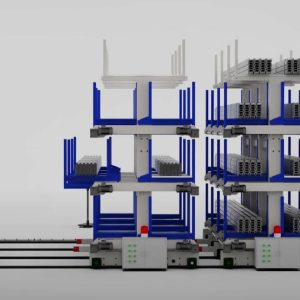

The cassette racking system emerges as the definitive answer to these challenges, representing a pinnacle of engineered storage technology specifically conceived for large-format, heavy sheet metal. This is not a simple shelving unit; it is a high-density, forklift-compatible storage system that redefines material handling paradigms. Its core design principle revolves around vertical integration and mechanized access, transforming storage from a passive, space-consuming activity into an active, streamlined component of the material flow. By enabling direct forklift interaction with entire batches of material, the system seamlessly bridges the gap between warehouse storage and production line need, ensuring that the right material is available at the right time with minimal effort and maximum safety.

A cassette racking system is architecturally defined by its series of individual steel cassettes—essentially heavy-duty trays or pallets—stacked vertically within a reinforced structural frame. Each cassette is engineered to cradle a full batch or pallet of sheet metal, whether steel, stainless steel, or aluminum. The entire system is designed for frontal access by a standard forklift, allowing operators to slide a cassette out, transport it to a processing machine like a laser cutter or press brake, and return it with equal ease. This design philosophy intentionally minimizes manual handling to the greatest extent possible. Workers are no longer required to engage in the dangerous and physically taxing process of manually unloading sheets from a static rack. Instead, the forklift handles the entire bundle, moving it as a single, secure unit. This method drastically reduces the risk of product damage from scratching or bending during retrieval and virtually eliminates the manual lifting injuries that plague less advanced storage environments.

The decision to implement a forklift-based sheet metal rack is particularly strategic for facilities managing large-format sheets, typically those up to 4000mm in length. In such environments, the challenges of manual handling are magnified, and the inefficiencies of non-specialized storage become acutely apparent. This system is engineered for both exceptional load capacity and the rigors of frequent forklift access, making it the optimal choice for operations where throughput efficiency and workplace safety are non-negotiable priorities. The key benefits are substantial and multifaceted. Firstly, it delivers truly high-density storage by stacking multiple tons of material vertically within a single, compact footprint, effectively multiplying storage capacity without expanding the facility’s footprint. Secondly, the entire operation is centered on forklift functionality, enabling the rapid loading and unloading of entire cassettes, which translates directly into faster machine changeovers and increased production uptime.

Most importantly, the system engenders a profound improvement in workplace safety by design. The need for personnel to manually lift or maneuver heavy sheets is removed, significantly reducing the potential for crush injuries, lacerations, and musculoskeletal disorders. Furthermore, these systems are not off-the-shelf products; they are fully customizable solutions. Parameters such as cassette dimensions, the number of vertical layers, and the load capacity per tray—which can typically reach up to 1500 kg—are all engineered to the specific requirements of the workshop. This customization ensures a perfect fit for both the materials being stored and the spatial constraints of the facility. The entire construction is heavy-duty, utilizing reinforced steel frame fabrication to guarantee longevity and reliability under the most demanding industrial conditions.

The applications for this type of storage system are extensive across metal-intensive industries. It is an indispensable asset for laser cutting factories that require quick access to a variety of materials for job changeovers. Sheet metal fabrication workshops benefit from the organized, efficient storage of raw materials for bending, welding, and assembly processes. Steel plate distribution and service centers utilize these racks to manage large inventories in a logical, accessible manner while protecting the material quality. Any warehouse tasked with bulk sheet metal storage will find that the vertical stacking capability of cassette racking liberates vast areas of floor space, which can then be reallocated to value-added production activities rather than passive storage.

In summary, for any business engaged in the handling of bulk sheet metal, the cassette racking system stands as a superior, forward-thinking investment. It is a space-saving, safety-enhancing, and forklift-compatible solution that directly addresses the core logistical challenges of the modern workshop. It goes beyond mere storage to actively improve storage density, workplace safety, and operational efficiency, providing a solid foundation for increased productivity and growth. As a certified manufacturer, Herochu produces cassette racking systems that meet CE, EU, and ISO 9001 standards, ensuring the highest levels of quality and safety. Our solutions are customizable to your specific workshop needs, with configurations available starting at $3,660, representing a significant return on investment through reclaimed space, enhanced safety, and streamlined workflow.