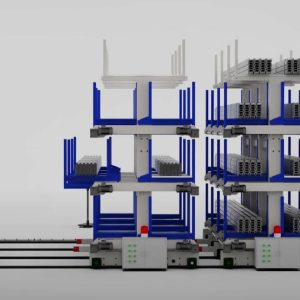

Heavy-Duty Steel Plate Organizer Shelf Drawer-Type Sheet Storage racks

Herochu’s Drawer-Type Sheet Storage racks are engineered to handle the toughest sheet metal storage challenges, especially in spaces with low lifting frames. Unlike flimsy shelving that sags under weight or static racks that block forklift access, our organizer shelves feature a reinforced carbon steel frame (10-gauge main structure, 7-gauge drawer supports) built to withstand constant use. The star of the design? Six full-extension drawers per unit—each rated to hold up to 3,000 kg (6,600 lbs) of sheet metal, from thin aluminum panels to thick steel plates. This strength ensures even 6000*2000mm steel sheets sit securely without warping, a common issue with cheaper storage solutions.

Herochu Heavy-Duty Steel Plate Organizer Shelf: Drawer-Type Storage for Streamlined Workshops

For workshops with low lifting frames or space constraints, managing stacks of metal sheets—iron, aluminum, stainless steel, and flat products—often feels like an endless battle. Forklift operators waste time navigating cluttered floors, sheets get bent or scratched when stacked haphazardly, and inventory checks turn into tedious hunts for specific sizes. Herochu’s Heavy-Duty Steel Plate Organizer Shelf—a premium line of Drawer-Type Sheet Storage racks—solves these frustrations with rugged construction, space-saving design, and intuitive access. Certified to CE, EU, and ISO 9001 standards, these fully customizable racks adapt to your workshop’s layout and material needs, starting at $3,099—turning chaotic storage into a productivity driver for metal fabricators, automotive shops, and precision engineering facilities.

Built for Heavy-Duty Workshop Demands

Herochu’s Drawer-Type Sheet Storage racks are engineered to handle the toughest sheet metal storage challenges, especially in spaces with low lifting frames. Unlike flimsy shelving that sags under weight or static racks that block forklift access, our organizer shelves feature a reinforced carbon steel frame (10-gauge main structure, 7-gauge drawer supports) built to withstand constant use. The star of the design? Six full-extension drawers per unit—each rated to hold up to 3,000 kg (6,600 lbs) of sheet metal, from thin aluminum panels to thick steel plates. This strength ensures even 6000*2000mm steel sheets sit securely without warping, a common issue with cheaper storage solutions.

The racks are purpose-built for low-clearance environments. With a maximum height of 65 inches (for models like the HC-B6020-65), they fit under low lifting frames where taller shelving would be unusable. A US-based HVAC manufacturer recently installed three HC-B4020-65 units in their 8-foot-clearance workshop and eliminated the need for floor stacking entirely—freeing up 200 square feet for a new assembly station. The secret lies in the vertical optimization: six layers of drawers turn a small footprint into massive storage capacity, with each unit holding up to 18,000 kg (39,600 lbs) of sheet metal total.

Standard Models Tailored to Your Sheet Sizes

Herochu’s Heavy-Duty Steel Plate Organizer Shelf comes in four pre-engineered models, each matched to common sheet dimensions—no need to overpay for custom sizing if your inventory fits standard specs:

- HC-B3015-63: Designed for 3000*1500mm sheets, this 63-inch-tall unit is perfect for small to mid-sized workshops handling standard aluminum or mild steel panels.

- HC-B4015-63: Fits 4000*1500mm sheets, ideal for automotive parts manufacturers storing longer steel blanks without sacrificing height clearance.

- HC-B4020-65: Accommodates 4000*2000mm sheets, a workhorse for fabricators dealing with larger flat products or tooling.

- HC-B6020-65: The largest standard model, built for 6000*2000mm heavy steel plates—common in construction and industrial equipment production.

Each model includes six drawers (plus an optional fixed top shelf for tools) and dedicated forklift ports on the drawer sides. This feature lets operators slide forks directly into the ports to load/unload sheets, eliminating the need for pallets or manual lifting. A mid-sized metal shop in Ohio switched from pallet racks to the HC-B4015-63 and cut material handling time by 40%—one operator can now retrieve a sheet in under a minute, compared to 2–3 minutes with their old system.

How the Drawer-Type Design Transforms Workflows

The roll-out drawer mechanism is the heart of Herochu’s storage solution, designed to make sheet management faster, safer, and more efficient—even in tight spaces:

1. 100% Drawer Extension for Full Access

Every drawer glides on precision ball bearings (rated for 15,000+ cycles) and extends completely from the rack. This means you can reach the back of the drawer with a forklift or crane without maneuvering around the rack—critical for workshops with narrow aisles. A spring-loaded locking pin keeps the drawer in place during loading/unloading, preventing accidental movement that could damage sheets or injure workers.

2. Flat Storage Prevents Damage

Sheets are stored horizontally in drawers, not stacked vertically—eliminating the pressure that causes bending, curling, or scratch marks. Rubberized liners in each drawer add extra protection, while the electrostatic powder coating (available in industrial gray, black, or custom colors) resists corrosion from metalworking fluids. A stainless steel fabricator in Florida reported a 60% drop in material waste after switching to Herochu’s racks, as sheets no longer get damaged during storage.

3. Clear Organization Simplifies Inventory

With six dedicated drawers, you can sort sheets by material type, thickness, or project—no more mixing aluminum and steel or guessing which stack has 16-gauge vs. 18-gauge panels. Labeled drawer fronts (included with every unit) make identification instant, while the open design lets you see stock levels at a glance. This clarity cut inventory check time by 50% for a Texas-based manufacturer, who now completes weekly counts in under an hour instead of two.

Fully Customizable for Your Unique Workshop

While Herochu’s standard models cover most needs, we know no two workshops are identical—and our Drawer-Type Sheet Storage racks adapt accordingly. Our design team works with you to tweak key features:

- Drawer Adjustments: Widen drawers beyond standard sizes (up to 12 feet) for custom sheet dimensions, or add dividers to split drawers for smaller panels or tools.

- Load Capacity Upgrades: Boost drawer capacity from 3,000 kg to 4,500 kg for extra-heavy plates, or reinforce the top shelf to hold 5,000 kg of bulky equipment.

- Low-Clearance Modifications: Shorten unit height (down to 50 inches) for workshops with extremely low lifting frames, without reducing drawer count.

- Special Add-Ons: Integrate barcode scanners for digital inventory tracking, add LED lights inside drawers for dim workshops, or install lockable drawers to secure high-value stainless steel or copper sheets.

A Pennsylvania-based aerospace parts maker customized their HC-B6020-65 units with 10-foot-wide drawers and barcode scanners. Within three months, they reduced order fulfillment errors by 35% and improved on-time delivery rates by 20%.

Certified Safety and Durability You Can Trust

In industrial settings, safety and compliance are non-negotiable—and Herochu’s Heavy-Duty Steel Plate Organizer Shelf delivers on both. Every unit undergoes rigorous testing to meet CE, EU, and ISO 9001 standards: load tests to 125% of rated capacity, impact tests to simulate forklift bumps, and corrosion resistance tests for harsh environments. The carbon steel frame is fire-resistant, and all moving parts comply with OSHA safety regulations, including anti-pinch guards on drawer rails.

This certification isn’t just paperwork—it’s real-world protection. A California fabricator noted that after installing Herochu’s racks, they passed their OSHA inspection with zero storage-related violations, a first in four years. The racks’ durability also translates to long-term value: with annual lubrication of drawer rails, they last 15+ years—far longer than the 3–5-year lifespan of budget racks.

Why Herochu’s Organizer Shelf Stands Out

When you invest in Herochu’s Heavy-Duty Steel Plate Organizer Shelf, you’re not just buying storage—you’re upgrading your entire operation. Here’s why businesses choose us:

- Space Savings: Reclaim up to 75% of floor space with vertical drawer storage, even in low-clearance workshops.

- Efficiency Gains: Cut material retrieval time by 40%+ with full-extension drawers and forklift compatibility.

- Damage Reduction: Store sheets flat to eliminate bending and scratches, saving thousands on wasted material.

- Safety Improvements: Reduce laceration risks from exposed edges and eliminate manual lifting, lowering injury rates.

- Fast ROI: Starting at $3,099, the racks pay for themselves in 6–12 months through cost savings and productivity gains.

Ready to Streamline Your Sheet Metal Storage?

Herochu’s Heavy-Duty Steel Plate Organizer Shelf—our premium Drawer-Type Sheet Storage racks—are the solution for workshops tired of clutter, damage, and inefficiency. Whether you need a standard HC-B3015-63 for small sheets or a customized unit for 6000*2000mm plates, our team will design a system that fits your space, inventory, and budget. Backed by global certifications and a 5-year warranty on parts, we stand behind every rack we build.

Contact us today to schedule a free workshop assessment and get a tailored quote for your system.

Q1: What steps should I take to start the procurement process?

You may get in touch with our backend technical staff first. Based on your specific parameters, we will formulate a suitable technical solution and provide a quotation. Alternatively, you can leave your contact details—such as WhatsApp, WeChat, or email address—and our professional sales team will reach out to you proactively.

Q2: How can I inform you of my need for suitable shelves?

You can share key information with us, including the type of items you plan to store on the shelves, the dimensions of those items, the quantity of shelves required, and any other specific details you have. With this information, we will develop a professional solution tailored to your needs. If you prefer, you can also leave your contact information, and our specialized team will contact you to address your questions.

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

To determine the right option, two key factors need to be considered first:

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

For a more accurate recommendation based on your specific needs, please leave your contact information, and we will provide targeted service.

Q4: Do you offer on-site installation and debugging services?

Yes, we do. We can dispatch professional technicians to your factory to carry out on-site installation and debugging of the robotic arm, and we will continue working until the equipment completes a successful trial operation. Our team has provided such services in many countries, including South Africa, the United States, Russia, South Korea, Qatar, Egypt, Lebanon, and Mexico.

Q5: What measures do you take to ensure product quality?

We have a comprehensive quality assurance system, supported by the following key measures:

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Our factory is located in Jinan, Shandong Province, China, specifically at No. 10 Industrial Park, Jiyang Street. It features a modern, standard workshop covering an area of 10,000 square meters.

Q7: How can I verify your company’s strength?

We offer two convenient ways for you to assess our company’s capabilities:

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

We are Jinan Constant Storage Machinery Manufacturing Co., Ltd., a high-tech enterprise that integrates research and development, production, sales, installation, and after-sales service. Our core product range includes intelligent sheet metal material warehouses, drawer-type sheet metal shelves, telescopic cantilever shelves, servo swing arm manipulators, gantry loading and unloading manipulators, fully automatic loading and unloading systems, and heavy-duty sheet metal and pipe storage shelves. Equipped with a professional technical team and advanced production equipment, we are committed to providing high-quality, high-performance mechanical products and customized solutions to customers around the world.

PRODUCTS

-

Heavy Duty Cantilever Racking System

New & Used Cantilever Racks | Heavy-Duty Storage Systems

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Heavy Duty Cantilever Racking System & Shelves

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Heavy-Duty Steel Plate Organizer Shelf Drawer-Type Sheet Storage racks

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Heavy Duty Telescopic Cantilever Storage System Metal Pipe Storage System Shelves

Read moreRated 0 out of 5