New & Used Cantilever Racks | Heavy-Duty Storage Systems

The key to this longevity is predictable design. Herochu’s cantilever racks eliminate the guesswork that leads to damage: every arm has a clearly marked capacity label, every column is anchored to prevent tipping, and every brace is engineered to distribute weight evenly. For used racks, this predictability is enhanced by our refurbishment process: we check for hidden wear, realign bent arms, and reinforce weakened connections, so you never inherit someone else’s maintenance headaches. Whether new or used, these racks are built to outlast the materials you store—making them a foundational asset, not a disposable tool.

Herochu New & Used Cantilever Racks: Heavy-Duty Storage Systems Built to Protect Your Investment

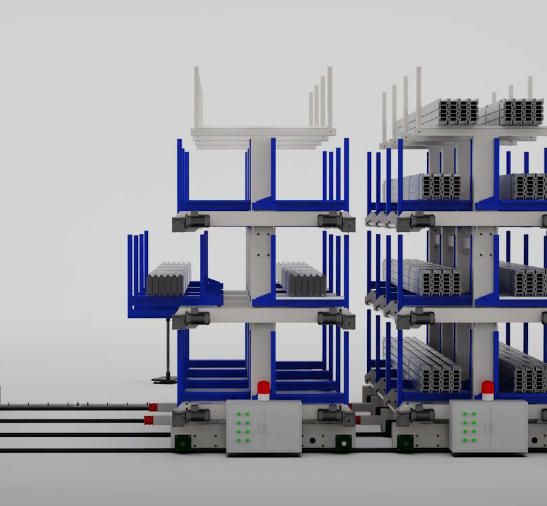

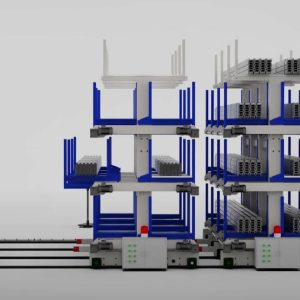

Investing in heavy-duty storage systems for long materials—whether steel pipes, lumber, or industrial profiles—is a commitment to efficiency. But the true value of that investment doesn’t end when the racks are installed. It grows over years of reliable use, driven by proper care, safety, and intentional maintenance. Herochu’s new & used cantilever racks—all certified to CE, EU, and ISO 9001 standards—are designed not just to organize your warehouse, but to thrive as long-term assets. Built with the durability to withstand decades of use and the flexibility to adapt to changing inventory needs, these systems turn one-time spending into ongoing returns—if you protect them the right way.

For facility managers, the difference between a cantilever rack that lasts 10 years and one that lasts 30 lies in daily habits: knowing load capacities, conducting regular inspections, and fostering a team culture of awareness. Herochu’s storage solutions are engineered to make this maintenance simple, turning “asset upkeep” from a chore into a natural part of operations. Whether you choose new racks for maximum customization or high-quality used racks for cost efficiency, our systems are built to reward careful stewardship—keeping your materials secure, your team safe, and your investment profitable.

Why Herochu’s New & Used Cantilever Racks Are Built for Long-Term Value

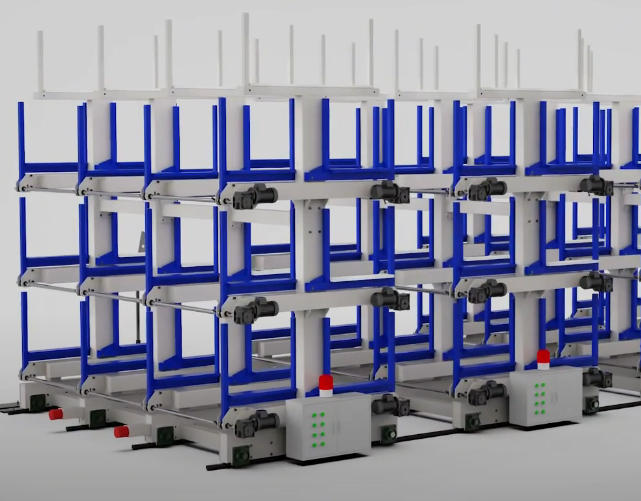

Not all heavy-duty storage systems are created equal. Generic racks often cut corners on material thickness or structural design, failing under repeated use or minor impacts. Herochu’s new cantilever racks are constructed from high-gauge, corrosion-resistant steel, with load-rated arms, reinforced columns, and anchorable bases that meet ISO 9001 quality standards. Each component is tested for strength before leaving our factory—ensuring the rack can handle 3–8 tons per layer without bending or shifting. This robust build means even our used racks—inspected, refurbished, and recertified by our engineers—deliver the same reliability as new units. We replace worn parts, retest load capacities, and reapply CE/EU-compliant safety labels, so you get a “like-new” system at a fraction of the cost.

The key to this longevity is predictable design. Herochu’s cantilever racks eliminate the guesswork that leads to damage: every arm has a clearly marked capacity label, every column is anchored to prevent tipping, and every brace is engineered to distribute weight evenly. For used racks, this predictability is enhanced by our refurbishment process: we check for hidden wear, realign bent arms, and reinforce weakened connections, so you never inherit someone else’s maintenance headaches. Whether new or used, these racks are built to outlast the materials you store—making them a foundational asset, not a disposable tool.

The Golden Rules of Protecting Your Cantilever Rack Investment

Your forklift operators are the first line of defense for your storage system. Training them on Herochu’s “Golden Rules of Safe Loading” prevents 90% of avoidable damage, ensuring your racks stay strong for years.

1. Always Respect Capacity Labels

Every arm and column on Herochu’s racks features a durable, weather-resistant label stating its maximum load. This isn’t a suggestion—it’s a safety and longevity requirement. Exceeding capacity, even by a small amount, causes permanent bending in arms or columns, reducing the rack’s lifespan and creating safety hazards. Remember: capacity ratings assume evenly distributed weight. A 20-foot steel bundle should rest on multiple arms along its length, not just at the ends, to avoid stress points.

2. Load from the Bottom Up

Herochu’s racks are engineered for stable weight distribution, but that balance depends on proper loading. Filling lower levels first keeps the rack’s center of gravity low, preventing tipping or swaying. This simple habit also makes retrieval safer: you won’t have to reach over top-heavy loads to access lower materials, reducing the risk of impacts or spills.

3. Place, Don’t Push

Forklift operators often rush to position loads, but pushing bundles into the rack from the aisle puts dangerous lateral stress on columns and arms. Herochu’s cantilever design lets you place materials directly on the arms—no pushing required. This gentle handling prevents dents, scrapes, and structural weakening that can lead to costly repairs down the line.

4. Ban Climbing—Absolutely

Herochu’s racks are built for storage, not access. Climbing leads to bent arms, dislodged bolts, and serious falls. Provide ladders or lift equipment for high-level retrieval instead—protecting both your team and your investment.

The 15-Minute Monthly Inspection That Saves Thousands

Preventative maintenance is the secret to extending your rack’s lifespan. Herochu recommends designating a team member to conduct a monthly visual inspection—quick checks that catch small issues before they become major problems. If any damage is found, unload the area immediately and contact our service team for repairs; never use a damaged rack.

What to Check:

- Columns: Look for forklift impacts (dents, bending) and ensure they’re perfectly vertical. Even a 1-degree lean indicates structural stress.

- Arms: Check for downward deflection (a sign of overloading) and secure locking pins/bolts. Loose hardware leads to arm failure over time.

- Bracing: Inspect horizontal and diagonal braces for straightness and tight connections. Bent bracing weakens the entire rack.

- Anchors: Ensure base bolts are tight with no gaps. Loose anchors are a top cause of rack tipping.

- Labels: Confirm capacity labels are legible. Faded or missing labels increase the risk of overloading.

For Herochu’s used racks, this inspection is even more critical—and easier. Our refurbishment process includes replacing worn labels, tightening all hardware, and reinforcing high-stress points, so your monthly check is just a verification, not a hunt for problems. We also offer annual professional inspections for both new and used systems, where our engineers test load capacity and identify hidden wear you might miss.

Cultivating a Culture of Asset Care

Safety and maintenance aren’t just checklists—they’re mindsets. Herochu’s clients who get the most value from their racks foster a “culture of awareness” around storage systems.

Institute a “No-Fault” Impact Reporting Policy

Forklift impacts happen, but hiding them leads to catastrophic failures. Encourage operators to report any contact with the rack—even minor scrapes—without fear of punishment. Our team can inspect the area and make repairs before small dents become structural cracks.

Keep Aisles Clear

Aisles are for maneuvering, not storage. Cluttered aisles force operators into tight turns, increasing the risk of impacts. Herochu’s cantilever racks are designed to maximize storage density without narrowing aisles—use that space wisely to protect both your racks and your team.

Add Affordable Protection

Column protectors and floor guardrails cost a fraction of rack repairs. Install them at aisle ends and high-traffic areas to absorb impacts before they damage your rack. Herochu offers custom-fit protectors for both new and used systems, ensuring a perfect match for your setup.

Why Herochu’s New & Used Cantilever Racks Stand Apart

When you choose Herochu’s new & used cantilever racks, you’re not just buying storage—you’re buying a partner in asset preservation. Our CE, EU, and ISO 9001 certifications guarantee that every rack (new or used) meets global safety and quality standards. Our team provides on-site training for your operators, on-demand repair services, and annual inspections to keep your system in top shape.

For facilities on a budget, our used racks offer unbeatable value: refurbished to like-new condition, backed by our warranty, and priced 30–40% lower than new units. For those needing customization, our new racks let you choose arm lengths (1.2m–3m), column heights (up to 6m), and accessories like pipe retainers or end stops—all engineered to work seamlessly with your materials.

Your cantilever rack is more than a storage system. It’s the backbone of your warehouse efficiency, the protector of your materials, and a long-term investment in your business. With Herochu’s new or used heavy-duty storage systems—and the simple habits to care for them—you’ll turn that investment into an asset that delivers value for decades.

Ready to protect your warehouse and your bottom line? Contact Herochu today to explore our new and used cantilever rack options, schedule a facility assessment, or get a custom quote.

Q1: What steps should I take to start the procurement process?

You may get in touch with our backend technical staff first. Based on your specific parameters, we will formulate a suitable technical solution and provide a quotation. Alternatively, you can leave your contact details—such as WhatsApp, WeChat, or email address—and our professional sales team will reach out to you proactively.

Q2: How can I inform you of my need for suitable shelves?

You can share key information with us, including the type of items you plan to store on the shelves, the dimensions of those items, the quantity of shelves required, and any other specific details you have. With this information, we will develop a professional solution tailored to your needs. If you prefer, you can also leave your contact information, and our specialized team will contact you to address your questions.

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

To determine the right option, two key factors need to be considered first:

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

For a more accurate recommendation based on your specific needs, please leave your contact information, and we will provide targeted service.

Q4: Do you offer on-site installation and debugging services?

Yes, we do. We can dispatch professional technicians to your factory to carry out on-site installation and debugging of the robotic arm, and we will continue working until the equipment completes a successful trial operation. Our team has provided such services in many countries, including South Africa, the United States, Russia, South Korea, Qatar, Egypt, Lebanon, and Mexico.

Q5: What measures do you take to ensure product quality?

We have a comprehensive quality assurance system, supported by the following key measures:

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Our factory is located in Jinan, Shandong Province, China, specifically at No. 10 Industrial Park, Jiyang Street. It features a modern, standard workshop covering an area of 10,000 square meters.

Q7: How can I verify your company’s strength?

We offer two convenient ways for you to assess our company’s capabilities:

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

We are Jinan Constant Storage Machinery Manufacturing Co., Ltd., a high-tech enterprise that integrates research and development, production, sales, installation, and after-sales service. Our core product range includes intelligent sheet metal material warehouses, drawer-type sheet metal shelves, telescopic cantilever shelves, servo swing arm manipulators, gantry loading and unloading manipulators, fully automatic loading and unloading systems, and heavy-duty sheet metal and pipe storage shelves. Equipped with a professional technical team and advanced production equipment, we are committed to providing high-quality, high-performance mechanical products and customized solutions to customers around the world.

PRODUCTS

-

Heavy Duty Cantilever Racking System

Long Goods Heavy Duty Cantilever Rack

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

New & Used Cantilever Racks | Heavy-Duty Storage Systems

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Heavy Duty Cantilever Racking System & Shelves

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Heavy-Duty Steel Plate Organizer Shelf Drawer-Type Sheet Storage racks

Read moreRated 0 out of 5