Automatic Loading and Unloading Systems of Laser Cutter

Herochu’s Automatic Loading and Unloading Systems for Laser Cuters represent the pinnacle of industrial automation, designed to maximize productivity while minimizing operational costs. Priced competitively from $12,288, these CE, EU, and ISO 9001-certified systems integrate seamlessly with existing laser cutting machines, transforming traditional workflows into high-efficiency automated processes.

Herochu Laser Cutting Automation: Precision, Efficiency, and Safety Redefined

1. Revolutionizing Laser Cutting with Fully Automated Systems

Herochu’s Automatic Loading and Unloading Systems for Laser Cuters represent the pinnacle of industrial automation, designed to maximize productivity while minimizing operational costs. Priced competitively from $12,288, these CE, EU, and ISO 9001-certified systems integrate seamlessly with existing laser cutting machines, transforming traditional workflows into high-efficiency automated processes.

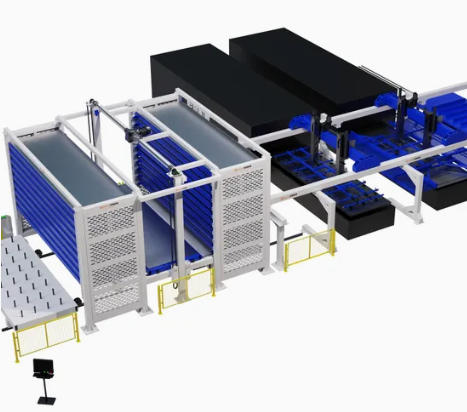

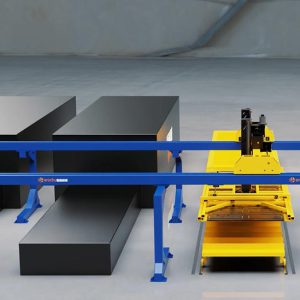

1.1 Core System Components

- 3D Storage Warehouse: Optimizes material storage with intelligent retrieval algorithms.

- Bilateral Gantry Truss: Ensures precise material handling with minimal floor space.

- Loading/Unloading Composite Truss Manipulator: Automates material transfer with sub-millimeter accuracy.

- PLC Control System: Centralized command interface for real-time monitoring and adjustments.

2. Automated vs. Manual Loading Systems

2.1 Manual Loading: Limitations of Traditional Methods

- Labor-Intensive: Requires constant operator intervention, increasing wage costs.

- Error-Prone: Human misalignment leads to material waste and machine downtime.

- Slow Throughput: Incompatible with high-volume production demands.

2.2 Semi-Automatic Systems: A Middle Ground

- Partial Automation: Reduces labor but still relies on operator input.

- Moderate Cost: Lower initial investment than full automation.

- Flexibility: Suitable for workshops with mixed production volumes.

2.3 Fully Automated Systems: The Herochu Advantage

- 24/7 Operation: Unmanned production cycles with zero idle time.

- Error Elimination: AI-driven positioning ensures 100% material alignment accuracy.

- ROI Acceleration: Pays for itself within 12-18 months through labor and waste savings.

3. Technical Specifications & Performance

| Parameter | Specification |

|---|---|

| Material Compatibility | Steel, aluminum, brass (0.5-25mm) |

| Cycle Time | 25% faster than semi-automatic systems |

| Energy Consumption | 30% lower than manual systems |

| Safety Features | Emergency stop, tilt detection |

4. End-to-End Support & Service

4.1 Pre-Sales Consultation

- Customized 3D simulations and ROI analysis.

4.2 Post-Sales Commitment

- 114 Service Protocol: 15-minute response, 1-hour troubleshooting, 4-hour resolution.

5. Competitive Edge

- Modular Scalability: Adaptable to workshop expansions.

- Global Compliance: Meets EU safety and environmental standards.

Contact Herochu today to transform your laser cutting workflow.

Q1: What steps should I take to start the procurement process?

Q2: How can I inform you of my need for suitable shelves?

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

Q4: Do you offer on-site installation and debugging services?

Q5: What measures do you take to ensure product quality?

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Q7: How can I verify your company’s strength?

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

PRODUCTS

-

Fiber Laser Automation Systems

Fully automatic loading and unloading system for Laser Cutting Machines

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Automatic Loading and Unloading Systems of Laser Cutter

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Flexible Solution for Laser Cutter’s Loading and Unloading System

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Loading and Unloading Systems of Laser Cutting Process

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Industrial Shelving Systems for Heavy-Duty Sheet Metal Storage

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Efficient Heavy Duty Horizontal Sheet Metal Storage Rack System

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Automatic warehouses for sheet metal storage

Read moreRated 0 out of 5