Herochu Automatic Loading & Unloading System for Laser Cutting Machines

Custom-Built for Your Workshop, Starting at $12,288 – CE, EU, ISO 9001 Certified

When every second on the shop floor translates into revenue, the difference between profit and delay is rarely the laser head itself—it is the invisible time between cuts. Herochu has engineered a fully integrated automatic loading and unloading ecosystem that erases those seconds, sheet after sheet, shift after shift. The result is a compact, modular production cell that turns a stand-alone laser into a 24-hour sheet-metal factory without adding labor, floor space, or uncertainty.

1. What You Receive

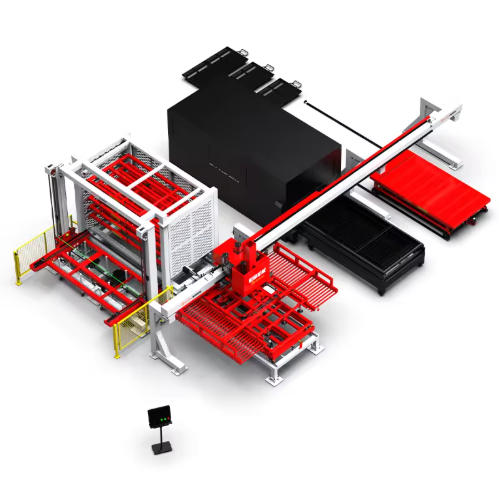

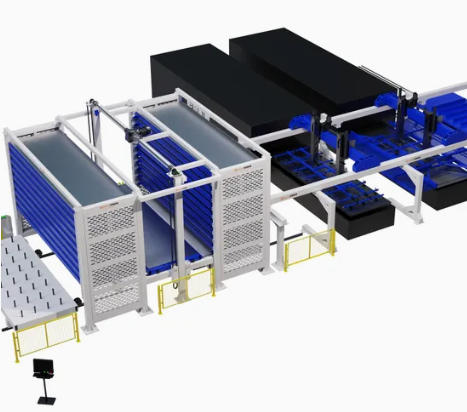

One purchase delivers a complete “plug-and-produce” unit:

- Three-dimensional storage warehouse – 2.5-ton capacity, 300 mm adjustable shelves, servo-driven extractor.

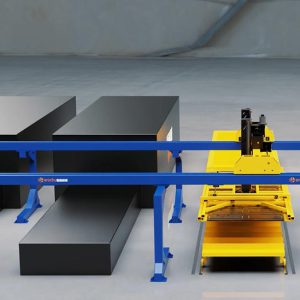

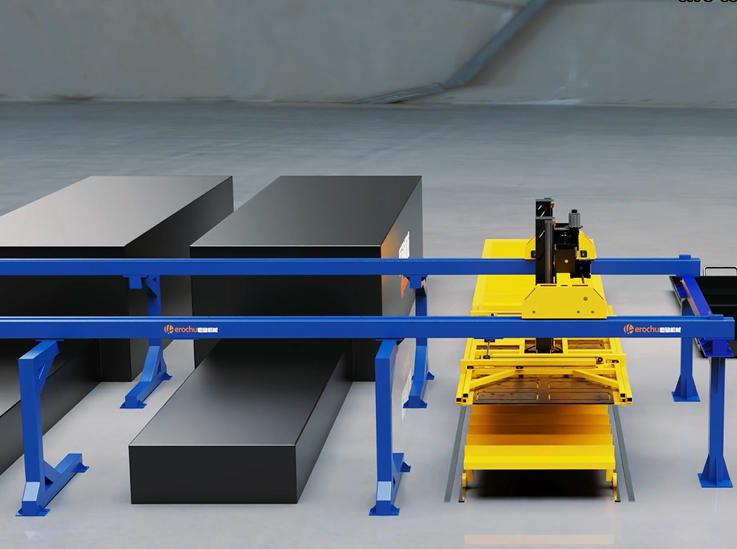

- Bilateral gantry truss – dual-side, dual-motor design, ±0.2 mm repeatability, 1.8 m/s traverse speed.

- Composite truss manipulator – vacuum & fork hybrid end-effector, 0.4 s sheet separation, 20 kg remnant handling.

- Finished-material truck – motorized exit conveyor with automatic stack squaring, 1,500 kg payload.

- PLC control system – Siemens S7-1500, Ethernet/IP ready, OPC-UA for MES handshake, remote diagnostics.

- Laser cutting machine interface – native drivers for Bystronic, Trumpf, Amada, Han’s, HSG, and Bodor; no third-party gateway required.

Every module arrives pre-wired and pre-tested on a single steel frame. Mechanical, electrical, and safety commissioning is completed in two shifts by our field team; production begins on the third morning.

2. How It Works in Practice

The operator parks a raw-material pallet at the infeed gate and presses “Start.” The warehouse shuttle selects the correct gauge, lifts it 0.1 mm above the stack to break micro-adhesion, and transfers it to the gantry pick-up zone. The gantry travels on hardened linear rails, positions the sheet over the laser table, and releases it with a controlled vacuum drop that prevents ghost shifts. While the cutter executes the nest, the gantry collects the previous job’s finished parts, places them on the outbound truck, and sweeps slag into a separate bin. Average cycle time: 38 seconds for a 3 m × 1.5 m × 2 mm mild-steel sheet—faster than most machines can finish the cut program.

3. Measurable Gains

- Throughput: 2.7× more sheets per shift compared with manual handling (client data, Czech Republic 2023).

- Labor: One operator can supervise three lasers; previous headcount was three operators for two lasers.

- Scratch-free surfaces: Vacuum cups leave no fork marks; secondary deburring eliminated.

- Inventory accuracy: RFID tags on each shelf update stock in real time; ERP reconciliation variance <0.3 %.

- Overtime reduction: 22 % decline in weekend shifts at a Dutch white-goods OEM within 60 days.

4. Customization Without Complexity

Herochu does not believe in “take-it-or-leave-it” automation. Tell us the maximum sheet weight you handle, the ceiling height you have, or the aisle width you cannot sacrifice, and we engineer around those numbers. Options include:

- Tower height from 2.8 m to 7.5 m (mezzanine compatible).

- Shelf width 1.5 m, 2.0 m, or 2.5 m; mixed gauges in the same rack.

- Second manipulator for tandem laser lines; shared warehouse cuts capital cost by 28 %.

- Sheet thickness sensor (0.4 mm–25 mm) prevents double-sheet pickup without compressed-air knives.

- Automatic remnant return – off-cuts >200 mm × 200 mm are bar-coded and stored for future nests, driven by SigmaNest or Lantek nesting engines.

All choices are priced à-la-carte; you only pay for the value you capture.

5. Safety & Compliance

The entire perimeter is enclosed by Category-4 safety light curtains and interlocked mesh. CE conformity covers EN ISO 12100, EN 13849-1 PL-e, and EN 60204-1. Every welded joint is ultrasonically inspected and documented in the hand-over binder; the system is also covered by EU Product Liability Directive insurance for €10 million.

6. Financial Justification

At 4,000 productive hours per year and an average shop rate of €75/hour, saving 35 seconds per sheet on 400 sheets per day equals €350,000 in additional billable laser time—payback in 4.2 months. Maintenance is limited to annual rail greasing and quarterly vacuum filter exchange; total yearly spend <€1,200.

7. Delivery & Uptime Promise

- Lead time: 45 calendar days for standard height, 60 days for custom.

- Installation: 48-hour mechanical, 24-hour electrical, 8-hour production trial with your own nests.

- Warranty: 24 months full coverage, 60 months on structural steel.

- Remote support: VPN within 15 minutes, 365 days, in English, German, Spanish, or Polish.

- Spare-parts kit: €499 includes belts, fuses, proximity sensors, and vacuum elements—ships same day from Rotterdam warehouse.

8. Next Step

Send us the DXF of your most common part, the hourly rate you charge, and the shifts you run. Within 24 hours you will receive a simulation report showing exact cycle times, labor savings, and ROI tailored to your accounting method. If the numbers justify the investment, we will reserve a production slot with no down-payment until you approve the final layout drawing.

Stop feeding your laser by hand; let Herochu feed your balance sheet instead.