Herochu Auto Loading & Unloading and Sheet Storage System of Fiber Laser Cutting Machine: Streamline Fiber Laser Production

For metalworking facilities leveraging fiber laser cutting machines—known for their speed, precision, and ability to handle diverse materials—manual or disjointed loading/unloading processes often undo the cutter’s efficiency. Herochu’s Auto Loading & Unloading and Sheet Storage System of Fiber Laser Cutting Machine solves this by integrating seamless material handling with secure storage, creating a fully automated sheet metal production unit. Starting at $12,288 and backed by CE, EU, and ISO 9001 certifications, this customizable system eliminates labor bottlenecks, reduces errors, and maximizes your fiber laser cutter’s output—ideal for high-volume production or facilities aiming to scale.

What Makes This System a Game-Changer for Fiber Laser Cutting

Fiber laser cutters excel at processing thin to thick metal sheets (and even tubes) with unmatched speed, but their performance hinges on how quickly and accurately materials move in and out. Manual loading forces operators to lift heavy sheets, align them by hand, and sort finished parts—wasting time, increasing injury risks, and introducing alignment errors that ruin cuts. Semi-automatic systems improve this but still require human intervention, limiting scalability.

Herochu’s solution is different: it’s a unified system that combines auto loading/unloading with built-in sheet storage, designed specifically to work in tandem with fiber laser cutters. No more cobbling together separate storage racks and handling equipment—this all-in-one setup ensures material flows from storage to cutter to finished product without gaps, keeping pace with your fiber laser’s rapid cycle times.

System Composition: Every Component Works in Harmony

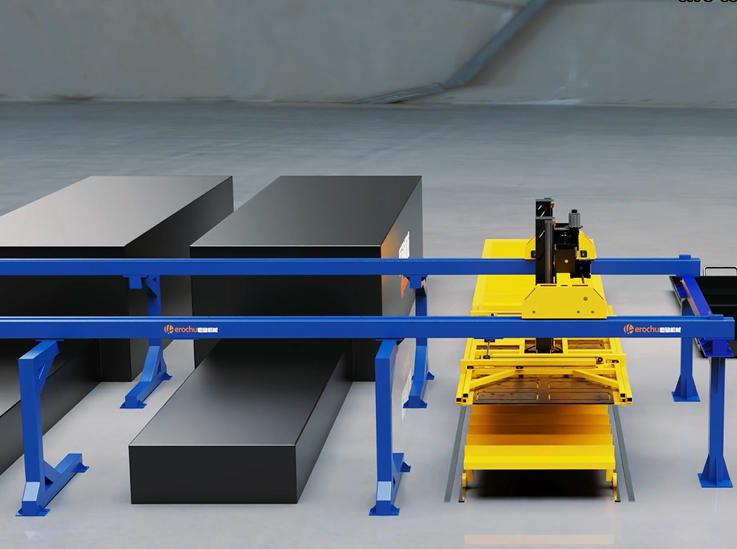

Herochu’s Auto Loading & Unloading and Sheet Storage System isn’t just a collection of parts—it’s a coordinated production unit built to streamline every step of material handling. The system includes six core components, each engineered to support fiber laser cutting’s unique demands:

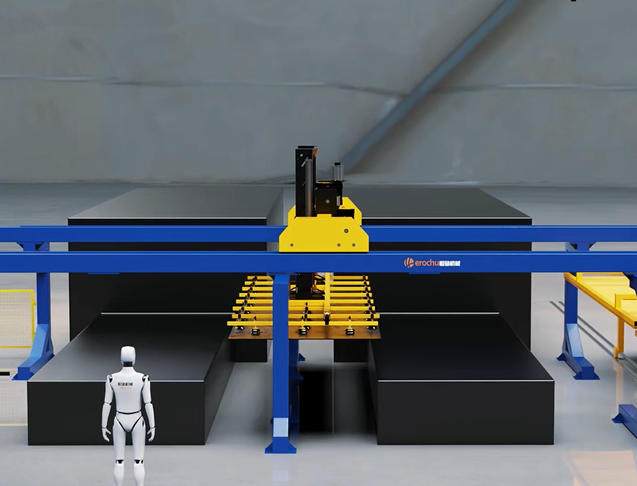

- Three-Dimensional Sheet Storage Warehouse: The backbone of the system, this warehouse uses vertical space to store raw metal sheets (or tubes) securely. Unlike traditional floor racks that clutter workshops and require manual searching, it centralizes inventory for fast, automated retrieval. Whether you’re storing thin aluminum sheets or thick steel plates, the warehouse scales to your volume—keeping materials organized and protected from damage.

- Bilateral Gantry Truss: Provides stable, precise horizontal movement for material transfer. The bilateral design lets the system access both sides of your fiber laser cutter (or multiple cutters, if configured), enabling simultaneous loading of raw sheets and unloading of finished parts. This eliminates downtime between jobs, as the system preps the next sheet while the cutter works.

- Loading and Unloading Composite Truss Manipulator: Equipped with a vacuum lifter (critical for delicate or heavy sheets), this manipulator handles the “heavy lifting” of fiber laser production. It gently picks up raw sheets from the storage warehouse, positions them exactly on the fiber laser’s bed (within ±1mm precision), and after cutting, uses suction cups to move finished parts to the next stage. Its composite truss construction balances strength and lightness—ensuring fast movement without bending or damaging materials.

- Finished Material Truck: Collects cut parts automatically, transporting them to a designated storage area. This eliminates manual sorting (a common source of scratches or warping for delicate fiber-cut parts) and keeps the workshop floor clear of finished inventory.

- PLC Control System: The system’s “brain,” with an intuitive touchscreen interface. You can program workflows (e.g., which sheets to cut first, where to store finished parts), monitor real-time status (e.g., storage levels, manipulator position), and adjust settings—no advanced technical skills needed. It syncs directly with your fiber laser cutter, so material transfer aligns perfectly with the cutter’s cycle.

- Seamless Integration with Fiber Laser Cutting Machine: The system is designed to work with most standard fiber laser cutter models, adapting to your existing equipment instead of requiring a replacement. It accounts for the fiber laser’s specific bed size, cutting speed, and material compatibility—ensuring no misalignment or delays.

Together, these components create a closed-loop workflow: raw sheets move from storage to fiber laser automatically, finished parts are transported to the material truck, and scrap is collected—all without manual intervention. The result? Your fiber laser cutter runs nonstop, turning more materials into high-quality parts every hour.

Customization: Built to Fit Your Fiber Laser Operation

Every fiber laser workshop is unique—some process thin aluminum sheets for electronics, others cut thick steel for construction. Herochu’s system adapts to your needs:

- Material Compatibility: Adjust the vacuum lifter’s strength and manipulator’s grip to handle your specific materials—from thin, flexible sheets to heavy, rigid plates (or even tubes). The storage warehouse’s shelves can be spaced to fit your sheet dimensions (e.g., 3015mm, 4020mm, 6025mm).

- Production Volume: For low-to-medium runs, configure the system to support one fiber laser cutter; for high-volume operations, scale it to serve 2–3 cutters simultaneously—maximizing your investment.

- Workshop Layout: The three-dimensional warehouse’s height and the gantry truss’s length can be tailored to your floor space, even in compact workshops. No more rearranging your facility to fit the system—Herochu’s solution fits you.

Our team works directly with you to assess your fiber laser’s specs, material types, and production goals—designing a system that integrates seamlessly from day one.

How It Compares to Other Loading/Unloading Solutions

To understand why Herochu’s system stands out, it’s critical to contrast it with common alternatives used in fiber laser workshops:

Shuttle Table Systems

Shuttle tables use 2–3 rotating tables to load, cut, and unload simultaneously—great for nonstop production. But they lack built-in storage: you still need separate racks for raw materials, and operators may need to refill tables manually. They also struggle with diverse material sizes—tables are fixed to specific dimensions, making them rigid for custom orders.

Herochu’s system adds built-in storage and flexible material handling, eliminating the need for separate racks and adapting to any sheet size. It also requires less floor space than shuttle tables, as the three-dimensional warehouse uses vertical space.

Pallet Changer Systems

Pallet changers use pre-loaded pallets of raw materials, swapping empty pallets for full ones automatically. They work well for high-volume runs of the same material but are limited by pallet size—you can’t easily switch between small and large sheets. They also don’t include finished part storage, so you need extra space for sorted parts.

Herochu’s system combines pallet-like storage (in the 3D warehouse) with flexible part handling, letting you switch between materials/sizes in minutes. It also includes the finished material truck, so you don’t need extra storage for cut parts.

Standalone Robotic Loaders

Robotic loaders handle material transfer but lack integrated storage—you still need manual storage racks, and the robot can’t access materials without operator help. They’re also often limited to specific material thicknesses, making them less flexible for fiber lasers that process diverse sheets.

Herochu’s system includes both automation and storage, so the robot (manipulator) always has access to raw materials. It also adapts to different thicknesses, making it ideal for fiber lasers that switch between jobs.

Herochu’s Advantage

Herochu’s system combines the best of these solutions—nonstop production (like shuttle tables), automated material swapping (like pallet changers), and flexible handling (like robots)—while adding built-in storage. It’s the only solution that addresses every pain point of fiber laser material handling in one setup.

Key Benefits for Fiber Laser Workshops

Herochu’s Auto Loading & Unloading and Sheet Storage System delivers tangible value that directly impacts your bottom line:

- Dramatically Lower Labor Costs: The system runs independently, reducing the need for operators by up to 70%. You no longer need workers to lift sheets, align them, or sort parts—freeing staff to focus on higher-value tasks (e.g., quality control, machine maintenance).

- 24/7 Unmanned Production: With built-in storage and automatic handling, the system can run for 8–12 hours without intervention—perfect for night shifts or facilities with limited staff. This boosts daily output by 30–50% compared to manual loading.

- Zero Alignment Errors: The composite truss manipulator positions sheets with ±1mm precision—critical for fiber laser cutting, where even small misalignments ruin parts. This reduces scrap rates by up to 25%, saving money on wasted materials.

- Safer Workshop: Automated handling eliminates manual lifting of heavy sheets, reducing the risk of strains, drops, or injuries. The PLC system includes safety safeguards (e.g., emergency stops, overload protection) to prevent accidents.

- Optimized Material Flow: The built-in storage warehouse keeps raw materials organized, so you never run out of stock mid-job. The finished material truck ensures cut parts are sorted immediately, reducing clutter and damage.

Certified Quality: Reliability for Fiber Laser Production

Fiber laser cutting demands consistency—even small system failures can halt production. Herochu’s system meets CE, EU, and ISO 9001 certifications, ensuring it adheres to global safety and performance standards:

- The three-dimensional warehouse uses high-grade carbon steel (Q235B or higher) for structural integrity, supporting heavy sheet stacks without warping.

- The manipulator’s vacuum lifter and suction cups are tested for durability, ensuring they don’t fail mid-lift.

- The PLC system undergoes 100+ hours of stress testing to ensure it works in industrial environments (e.g., dust, temperature changes).

Before shipment, every system is tested with your specific material type and fiber laser model—ensuring it performs flawlessly from day one.

Is This System Right for Your Fiber Laser Workshop?

Herochu’s system is ideal if:

- You use a fiber laser cutter and struggle with manual loading/unloading bottlenecks.

- You want to run unmanned shifts or increase daily output.

- You process diverse material sizes/thicknesses and need flexible handling.

- You want to reduce scrap rates and labor costs.

It’s less suited for tiny workshops with extremely low production volumes (e.g., 1–2 sheets per day)—but for most fiber laser operations, the ROI is clear: the system pays for itself in 6–12 months via labor savings and increased output.

Why Choose Herochu?

In a market flooded with generic automation tools, Herochu focuses on fiber laser-specific needs:

- We understand the unique demands of fiber laser cutting (e.g., precision, speed, material diversity) and design our system to support them.

- Our customization process ensures the system fits your existing fiber laser, no replacement required.

- Starting at $12,288, it’s affordable for small-to-mid-sized workshops—without sacrificing quality.

- We back every system with responsive support: if you have an issue, our team provides a 15-hour response time and resolves problems within 4 hours (per our “114” service commitment).

For fiber laser workshops ready to stop letting manual loading hold back their cutter’s potential, Herochu’s Auto Loading & Unloading and Sheet Storage System of Fiber Laser Cutting Machine is the solution. It’s not just automation—it’s a way to turn your fiber laser into a more profitable, reliable, and efficient production tool.

Contact Herochu today to discuss your fiber laser’s specs and workshop needs—let’s design a system that helps you cut more, waste less, and grow faster.