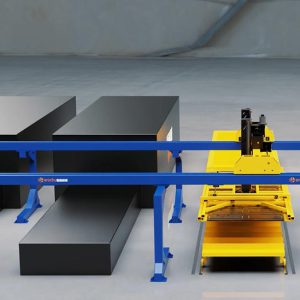

Heavy Duty Sheet Metal Storage Racks of Warehouse

For warehouse and operations managers, the challenge of storing sheet metal is a constant balancing act. On one side, there is the imperative to maximize storage density within a finite and expensive footprint. On the other, there is the relentless pressure to control costs, not only the initial capital outlay but the ongoing operational expenses that erode profitability. Traditional storage methods often fail on both fronts, leading to wasted space, high labor intensity, and costly material damage. The Herochu Heavy Duty Sheet Metal Storage Rack is engineered as a definitive solution to this dilemma. This is not merely a piece of equipment; it is a strategic investment designed to deliver a compelling return by transforming a costly operational bottleneck into a model of efficiency and control. With a starting price of $3,660 for a customizable unit, the system pays for itself by systematically addressing the core financial drains of conventional storage.

Herochu Heavy Duty Sheet Metal Storage Racks: A Strategic Investment in Warehouse Efficiency

For warehouse and operations managers, the challenge of storing sheet metal is a constant balancing act. On one side, there is the imperative to maximize storage density within a finite and expensive footprint. On the other, there is the relentless pressure to control costs, not only the initial capital outlay but the ongoing operational expenses that erode profitability. Traditional storage methods often fail on both fronts, leading to wasted space, high labor intensity, and costly material damage. The Herochu Heavy Duty Sheet Metal Storage Rack is engineered as a definitive solution to this dilemma. This is not merely a piece of equipment; it is a strategic investment designed to deliver a compelling return by transforming a costly operational bottleneck into a model of efficiency and control. With a starting price of $3,660 for a customizable unit, the system pays for itself by systematically addressing the core financial drains of conventional storage.

The most immediate and calculable return comes from a dramatic improvement in space utilization. Traditional vertical stacking or makeshift solutions consume valuable square footage with poor density and inaccessible inventory. The Herochu rack’s horizontal, high-density design can increase your effective storage capacity by 25 to 30 percent. This is achieved by utilizing the full cubic volume of your facility with a configuration that eliminates the dead space inherent in other methods. For a company facing a monthly warehouse rent of $7,000, a 30% gain in efficiency equates to approximately $25,200 in annualized rental savings, effectively paying for the rack system itself in a matter of months while freeing up space for other productive uses or delaying the need for a costly facility expansion.

Beyond real estate savings, the system delivers profound labor cost reductions. The traditional process of retrieving a single sheet from a stack often requires multiple employees and significant time, involving moving other materials and risking damage. The Herochu design, featuring fully extendable, heavy-duty drawers, revolutionizes this workflow. It enables true single-operator access. An employee can simply open a door, slide out the desired drawer, and use an overhead crane or vacuum lifter to retrieve the exact sheet needed without disturbing the rest of the inventory. User reports consistently indicate this can reduce retrieval times by 30 to 40 percent, allowing your workforce to accomplish more in less time and significantly cutting labor expenses. One warehouse supervisor noted that the system allowed them to reallocate personnel to more value-added tasks, improving overall operational throughput.

Material preservation represents another critical component of the ROI equation. Sheet metal is a high-value commodity, and any damage from scratching, bending, or edge deformation directly impacts the bottom line through scrap, rework, or customer rejections. The horizontal storage method is inherently protective. By supporting each sheet fully and preventing the friction and point loads of vertical stacks, the Herochu rack drastically reduces the incidence of damage. Facilities have reported reductions in material loss by up to 40 percent, a saving that flows directly to the bottom line and protects the quality of your final product. This combination of space optimization, labor efficiency, and material savings creates a powerful financial argument. When you invest in a CE, EU, and ISO 9001 certified Herochu rack, you are not just buying storage; you are purchasing a proven tool for cost control and operational excellence, engineered for the demands of a heavy-duty warehouse environment.

Q1: What steps should I take to start the procurement process?

Q2: How can I inform you of my need for suitable shelves?

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

Q4: Do you offer on-site installation and debugging services?

Q5: What measures do you take to ensure product quality?

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Q7: How can I verify your company’s strength?

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

PRODUCTS

-

Sheet Metal Storage Racks

Heavy Duty Sheet Metal Storage Racks of Warehouse

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Choose the Right Sheet Racking Systems & Storage Racks

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Choosing the Right Sheet Steel Storage Rack for Maximum Space Efficiency & Organization

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Fully automatic loading and unloading system for Laser Cutting Machines

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Automatic Loading and Unloading Systems of Laser Cutter

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Flexible Solution for Laser Cutter’s Loading and Unloading System

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Loading and Unloading Systems of Laser Cutting Process

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Industrial Shelving Systems for Heavy-Duty Sheet Metal Storage

Read moreRated 0 out of 5