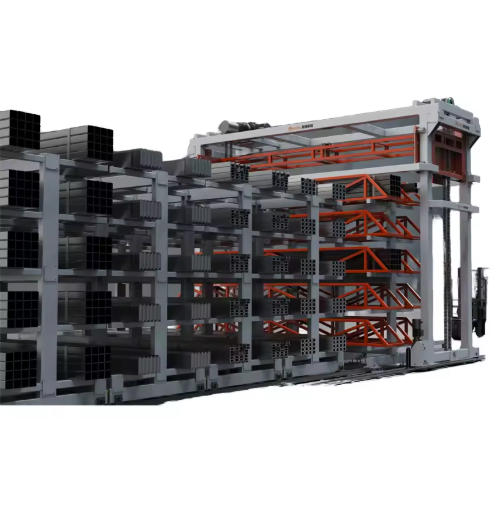

Herochu Pipe Store Long Span Goods Automated Storage System: Smart Storage for Lengthy, Heavy-Duty Materials

For warehouses, manufacturing plants, and distribution centers struggling to manage long span goods—from steel pipes and metal profiles to bundled bars—traditional storage solutions often fall short: wasted vertical space, slow retrieval times, and safety risks from manual handling. The Herochu Pipe Store Long Span Goods Automated Storage System transforms these pain points into strengths, leveraging automation to maximize capacity, streamline operations, and enhance workplace safety. Certified to meet global quality standards (CE, EU, ISO 9001), fully customizable to your workshop’s layout, and starting at $39,998, this system is an investment that takes your warehouse efficiency to new heights—whether you’re storing single profiles or bulk bundles.

System Composition: Engineered for Seamless Automation

At the core of the Herochu Pipe Store Long Span Goods Automated Storage System is a integrated set of components designed to work in harmony, eliminating manual bottlenecks and ensuring consistent performance. The system includes:

- Loading & Unloading Gantry System: Handles the movement of long span goods to and from the storage towers, reducing the need for manual lifting or forklift operation.

- Profile Material Racks: Sturdy, high-load-bearing structures that form the backbone of the storage system, designed to accommodate single or bundled profiles of varying types.

- Material Frames: Securely hold goods within the racks, preventing shifting during automated movement and protecting delicate or high-value materials.

- Guide Rails: Ensure smooth, precise movement of the lift unit and material frames, minimizing wear and tear while maintaining operational accuracy.

Every component is built for durability— the main structure boasts exceptional load-bearing capacity, making it suitable for heavy-duty industrial use. Whether you’re storing 3T or 5T loads per layer, the system remains stable, even with frequent automated cycles.

Key Specifications: Tailored to Long Span Goods Needs

Herochu’s Pipe Store Long Span Goods Automated Storage System is engineered to fit the unique dimensions and weight requirements of long span materials. Below are the core technical specifications, with full customization available to match your workshop’s space and inventory:

| Specification | Details |

| Standard Lengths | 6015mm, 6020mm, 6025mm (custom lengths available for unique goods) |

| Number of Floors | 8–13 layers (adjustable to maximize vertical space in your warehouse) |

| Load per Layer | 3T or 5T (upgrade options for heavier materials available) |

| Mode of Movement | Linear guide rail + chain (ensures smooth, precise horizontal motion) |

| Transmission Mode | Chain drive (reliable, low-maintenance operation for heavy loads) |

| Vertical Lifting Speed | 9m/min (fast enough to reduce wait times, steady enough for safety) |

| Inlet/Outlet Speed | 12m/min (speeds up loading/unloading to keep workflow moving) |

| Profile Support | Optional configurations (customized to match your material type—pipes, bars, profiles) |

Note: Customization is central to this system. Beyond standard specs, we adjust the number of layers to fit your warehouse’s ceiling height, modify load capacities to handle extra-heavy bundles, and tailor profile support to match your specific inventory (e.g., specialized frames for fragile pipes). Our team works with you to design a system that aligns with your space and workflow.

How It Works: Automation That Simplifies, Not Complicates

The Herochu Pipe Store Long Span Goods Automated Storage System is designed for intuitive operation—no advanced technical expertise required. At the heart of the system is the Automatic Tower, a vertical storage unit that optimizes height utilization to store more goods in less floor space. Here’s how it functions:

- Request & Retrieve: At the touch of a button on the system’s touch panel, select the desired material. The lift unit automatically locates the corresponding shelf within the tower.

- Smooth Movement: The lift unit glides along linear guide rails (powered by chain drive) to pull the shelf out of the rack, then lowers it to an ergonomic working height—eliminating the need for ladders or heavy lifting.

- Load/Unload: Once at working height, operators can safely load or unload materials. For bundled goods, the material frames keep items secure, preventing spills or damage.

- Auto-Storage: After loading/unloading, the lift unit automatically returns the shelf to its original position in the tower—no manual pushing or positioning required.

A comprehensive sensor package ensures safety at every step: sensors detect obstacles, prevent overloading, and stop movement if an operator is in the danger zone, minimizing accident risks.

Unmatched Advantages: Why Automation Beats Manual Storage

The Herochu Pipe Store Long Span Goods Automated Storage System solves the most pressing challenges of managing long span goods, offering benefits that manual racks simply can’t match:

- Space-Saving Vertical Utilization: Unlike traditional racks that waste ceiling height, this system uses every inch of vertical space—doubling or tripling storage capacity in the same floor area. Ideal for warehouses where space is at a premium.

- Individual Compartments for Organization: Each compartment is tailored to your needs—different usable heights can be implemented in a single tower, and optional dividers let you subdivide spaces for specific material types. No more mixing pipes with bars or searching through disorganized bundles.

- Time-Saving Operation: The touch panel displays real-time material information (location, quantity, type) at a glance, so operators never waste time hunting for goods. Automated retrieval cuts down on retrieval time by up to 70% compared to manual systems.

- Operator Safety & Ergonomics: Automation reduces manual handling, lowering the risk of strains or injuries. Compartments are lowered to working height, so no bending, reaching, or climbing is needed—minimizing physical effort for your team.

- ERP Compatibility for Full Workflow Integration: For facilities using ERP systems, an optional link connects the storage system to your software, creating a fully automated process from customer order receipt to goods dispatch. This eliminates manual data entry, reduces errors, and keeps inventory records up-to-date in real time.

Why Choose Herochu?

In industrial storage, automation is only valuable if it’s reliable, customizable, and easy to use—and the Herochu Pipe Store Long Span Goods Automated Storage System delivers on all three. It’s ISO 9001-certified, so you can trust its durability and performance in heavy-duty environments. Its modular design means it grows with your business: add more towers, adjust layers, or upgrade load capacities as your inventory expands.

Starting at $39,998, this system is an investment that pays off in reduced labor costs, faster order fulfillment, and maximized storage space. Whether you’re a mid-sized manufacturer storing 6-meter pipes or a large distributor managing 12-meter bundled bars, the Herochu Pipe Store Long Span Goods Automated Storage System transforms your warehouse into a lean, efficient operation.

Don’t settle for outdated, manual storage—contact Herochu today to discuss your custom Pipe Store Long Span Goods Automated Storage System. Our team will work with you to design a solution that fits your workshop, your inventory, and your budget.