The Hidden Costs of Inefficient Storage

Warehouse managers across industries face a common dilemma: limited space and growing inventories. Traditional storage methods—stacking sheets vertically or using static racks—waste up to 60% of usable space while creating safety hazards and operational delays. Inefficient storage isn’t just about clutter; it directly impacts your bottom line through:

- Lost productivity: Workers spend 30% of their time searching for materials.

- Increased labor costs: Manual handling adds unnecessary hours to workflows.

- Material damage: Improper storage leads to scratches, dents, and misalignment.

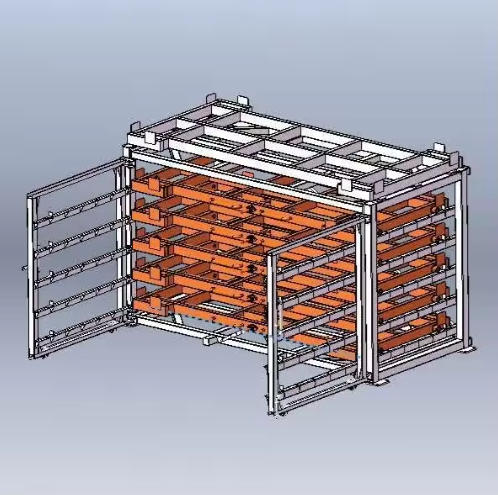

Herochu’s CE, EU, and ISO 9001-certified steel storage racks address these challenges head-on. Starting at $3,660, our Roll-Out Sheet Metal Storage Racks are engineered to maximize space, improve safety, and boost efficiency—without costly facility expansions.

Why Traditional Storage Methods Fail

- Vertical Stacking:

- Static Racks:

- Pain Point: Fixed shelves can’t adapt to varying sheet sizes (2000x1000mm to 3000x1500mm).

- Herochu Solution: Modular design lets you adjust partitions and widths as inventory changes.

- Floor Storage:

- Pain Point: Cluttered aisles slow forklift traffic and create tripping hazards.

- Herochu Solution: Vertical systems reclaim 35% of floor space, improving workflow efficiency.

Key Features of Herochu’s Storage Racks

| Model | HC-V2010-15 | HC-V2513-15 | HC-V3015-15 |

|---|---|---|---|

| Plate Size | 2000x1000mm | 2500x1500mm | 3000x1500mm |

| Load | 1T/layer | 1T/layer | 1T/layer |

| Drawer Speed | 12m/min | 12m/min | 12m/min |

- Heavy-Duty Framework: Welded steel supports 5,500 lbs./shelf (expandable to 10,000 lbs.).

- Ergonomic Design: Pull-out drawers reduce strain injuries by 90%.

- Compatibility: Works seamlessly with vacuum lifters, hoists, and forklifts.

Case Study: A Metal Fabrication Facility’s Transformation

A Detroit-based manufacturer replaced their outdated racks with Herochu’s HC-V3015-15 system:

- Space Savings: Stored 400% more material in the same footprint.

- Efficiency: Retrieval time dropped from 15 minutes to 4 minutes per sheet.

- Safety: Eliminated manual lifting injuries, reducing worker’s comp claims by 70%.

Five Common Warehouse Pain Points (And How Herochu Solves Them)

- Wasted Space:

- Problem: Vertical stacking leaves 50% of ceiling space unused.

- Solution: 15-tier racks maximize vertical storage.

- Inflexible Racking:

- Problem: Fixed shelves can’t accommodate varying sheet sizes.

- Solution: Adjustable partitions (50mm height) for custom fits.

- Chaotic Layouts:

- Problem: Poor zoning slows material flow.

- Solution: Logical grouping by frequency of use.

- Manual Handling:

- Problem: Labor-intensive processes create bottlenecks.

- Solution: Pull-out drawers + lifters automate workflows.

- Inventory Errors:

- Problem: Manual tracking leads to stockouts.

- Solution: Pair with barcode WMS for real-time updates.

Future-Proof Your Warehouse

Herochu’s systems aren’t just storage—they’re scalable assets that grow with your business:

- Expandable: Add tiers or widen racks as inventory increases.

- Low Maintenance: Chain-driven systems ensure 10+ years of reliability.

- Safety-Centric: Reinforced steel frames prevent collapse risks.

Ready to Optimize Your Space?

Contact us for a free facility assessment and discover how Herochu’s steel storage racks can transform your operations.

Space is finite. Innovation isn’t.