Unlocking Unprecedented Productivity: The Strategic Advantages of Automatic Loading and Unloading Systems for Fiber Laser Cutters

In the precision-driven world of metal fabrication, the fiber laser cutter has established itself as an indispensable tool, renowned for its cutting speed and accuracy. However, the true measure of a production cell’s output is not solely determined by the laser’s beam-on time. The critical intervals dedicated to loading raw sheets and unloading finished parts represent significant, recurring bottlenecks. These manual interventions halt production, introduce variability, and constrain the overall throughput of even the most advanced laser machinery. For fabricators aiming to scale their operations and improve margins, addressing this logistical challenge is paramount.

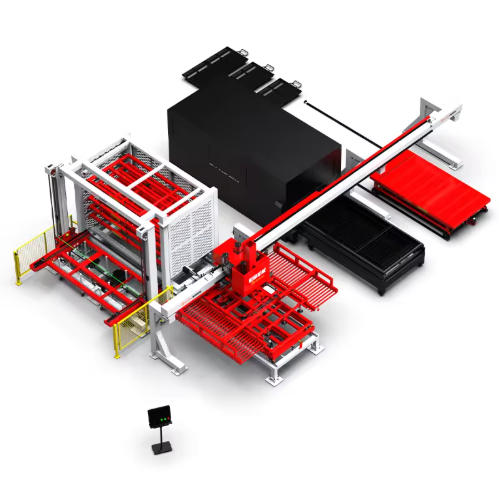

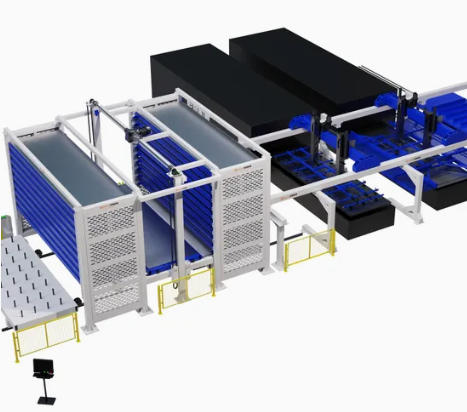

The integration of an automatic loading and unloading system for a fiber laser cutter is the definitive solution to this operational impediment. This technology transforms a standalone machine into a continuous, integrated production unit. A Herochu system, comprising a three-dimensional storage warehouse, a bilateral gantry truss, a loading and unloading composite truss manipulator, a finished material truck, and a centralized PLC control system, works in concert with the laser cutter to create a seamless workflow. This holistic approach goes beyond mere automation; it represents a fundamental re-engineering of the production process designed to effectively guarantee product quality, improve production efficiency, and reduce production costs on a significant scale.

The following analysis delves into the core advantages of adopting this technology, illustrating why it has become a strategic imperative for competitive fabricators.

A Paradigm Shift in Operational Efficiency

The most immediate and impactful advantage of an automated system is the dramatic improvement in efficiency. Manual loading and unloading are inherently time-consuming processes. An operator must physically handle each sheet, position it on the bed, and after cutting, remove the skeleton and sort the parts. This cycle repeats for every sheet, leading to substantial cumulative downtime.

An automatic system obliterates this bottleneck. Robotic manipulators, guided by the PLC, execute loading and unloading sequences with relentless speed and precision. The process becomes a continuous loop: as a finished sheet is unloaded, a new raw sheet is simultaneously or immediately thereafter positioned. This eliminates the dead time between jobs, allowing the fiber laser to operate at its maximum potential utilization rate. The system’s ability to function tirelessly enables extended production runs and even 24/7 lights-out manufacturing, thereby multiplying the return on investment for the entire laser cutting cell.

Uncompromising Consistency and Product Quality

In fabrication, consistency is synonymous with quality. Manual handling introduces a degree of variability that can affect the final product. Slight misalignments during loading, even by a few millimeters, can impact nesting efficiency and cut quality, especially on intricate designs. Human factors such as fatigue can lead to inconsistencies over a long shift.

An automatic loading and unloading system for fiber laser cutters eradicates this variability. Through precise servo motors and advanced vision systems, the manipulator places every single sheet in the exact same position with micron-level accuracy. This repeatability ensures that the laser’s cutting path is perfectly aligned with the material for every job. The result is a guaranteed consistency in part quality, reduced scrap rates due to optimal material utilization, and the ability to maintain tight tolerances batch after batch without deviation. This level of control is simply unattainable with manual operations.

Cultivating a Safer Workshop Environment

Worker safety is a non-negotiable priority in any industrial setting. Manual sheet metal handling presents inherent risks, including musculoskeletal injuries from lifting heavy plates, potential accidents with sharp-edged materials, and exposure to the laser cutting area during loading and unloading.

Automating this process fundamentally enhances workplace safety. By removing personnel from the direct handling of heavy and sharp materials, the risk of physical strain and laceration injuries is vastly diminished. Operators are no longer required to enter the immediate vicinity of the laser cutting bay during operation, mitigating any potential safety hazards associated with the equipment. The workforce can be reallocated to supervisory, programming, and quality control roles, which are safer and add greater value to the operation. This proactive approach to safety not only protects employees but also reduces potential liabilities.

A Compelling Reduction in Operational Costs

While the initial investment is a consideration, an automatic system delivers a substantial reduction in long-term operational costs. The most evident saving is in direct labor costs. The system’s autonomy reduces the need for multiple operators dedicated solely to material handling, allowing a single skilled technician to manage several automated cells simultaneously.

Furthermore, the efficiency gains translate directly into lower cost-per-part. Increased throughput means fixed overheads are amortized over a larger output. Reduced scrap rates through precise material handling contribute to raw material savings. The capability for unattended operation allows for production during off-peak hours, optimizing energy costs and maximizing the utility of the facility. When these factors are combined, the total cost of ownership is favorably altered, justifying the capital expenditure through a compelling and calculable return on investment.

Herochu Configurations for Diverse Production Needs

Recognizing that fabrication shops have varying requirements, Herochu offers a range of automated solutions, each customizable to your workshop’s specific dimensions and production volume, starting at $12,288. All systems are CE, EU, and ISO 9001 certified, ensuring adherence to the highest international standards for safety and quality.

For operations focused on high-volume processing of standard-sized sheets, the Smart Automatic Sheet Metal Loading and Unloading system handles sheets from 1×0.6m up to 4x2m, with a thickness capacity of 1-15mm. Its straightforward design offers a cost-effective entry into automation for batch production.

For larger formats and greater intelligence, the Smart Automatic Sheet Metal Loading, Unloading and Storage System manages sheets up to 6x2m. Its unique dual-working-head design enables ultra-high-speed cycling and can be expanded to include visual inspection and finished part sorting. This system can even be networked to feed multiple laser cutting machines.

Where floor space is a premium, the Smart Compact Sheet Metal Storage Tower provides a vertical storage solution. This integrated system offers a one-stop solution for storage, cutting, and sorting with a minimal footprint, handling sheets from 2x1m to 4x2m.

For maximum flexibility, our standard Smart Automatic Sheet Metal Loading and Unloading unit features a compact structure and versatile layout options, capable of handling a wide range of sheet sizes from 0.5x1m to 6x2m, with a single plate weight capacity of up to 750kg.

In conclusion, the advantages of integrating an automatic loading and unloading system for your fiber laser cutter are clear and multifaceted. It is an investment that pays dividends not just in speed, but in quality, safety, and overall operational economy. By automating the material flow, you empower your laser cutter to achieve its full productive potential, positioning your business for growth in an increasingly competitive market. To explore how a customizable Herochu system can transform your workshop, contact our engineering team for a detailed consultation.