Herochu Automated Storage System for Bars, Pipes & Tubes – turn sixteen aisles of cantilever chaos into one quiet, 40-metre lane that delivers the right stock to the right saw, cell, or shipping dock in under ninety seconds. Built for mills, service centres and OEM fabricators who feed JIT lines from 3 m copper busbar to 12 m sour-service casing, the system begins at USD 42,000 for a six-cassette starter bay and scales without theoretical limit. Every weld, sensor and gearbox is governed by CE, EU Machinery Directive and ISO 9001 certificates that arrive with the machine, not six months later.

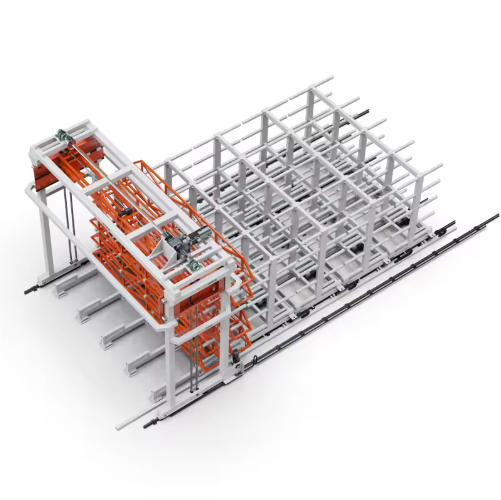

The skeleton is a welded, stress-relieved gantry frame rated for 5 t per level and 60 t per tower. Hot-rolled ASTM A992 columns are milled flat to ±0.2 mm so the linear guide rails—THK SRG type, 65 mm wide—run silent at 9 m/min vertical speed and 12 m/min shuttle speed. Chain drive is Renold Synergy 16B-2 with labyrinth lube channels; expected service life before elongation reaches 0.25 % is 28,000 operating hours at 80 % duty cycle. Cassettes are bolted to the chain at 300 mm pitch intervals; therefore a 6,025 mm high tower delivers up to thirteen storage levels, yet can be lowered to eight if roof beams or crane hooks intrude. Should your product mix shift from 50 mm bar to 300 mm beam, swap the cassette fingers in thirty minutes and keep the same drive motor—no re-commissioning required.

Loading and unloading are handled by a twin-mast gantry that straddles the rack face. The cross-travel beam carries a telescopic fork set rated 3 t with sideshift, rotate and +/-1 mm repeatability thanks to a SICK bar-code tape and SEW servo drives. One operator places a bundle on the inbound conveyor; the gantry identifies length, diameter and weight via a pre-scan light grid, then parks the load in the first optimal cube. If the WMS detects a partial remnant returning from the saw, the gantry automatically chooses a remnant pocket so full-length stock remains accessible. No manual strapping removal, no fork truck ballet, no overtime premium for night-shift riggers.

Floor space contracts dramatically. A conventional 500 t inventory of 6 m stainless bar occupies roughly 420 m² plus 1.8 m service aisles on both sides. The Herochu system stores the same tonnage in 54 m²—an 87 % reduction—because the gantry needs only 700 mm frontal clearance and zero human aisle. The released square metres can host a second laser cell or be rented out; either way the payback clock starts the moment concrete is freed.

Vertical cube is just as ruthlessly exploited. Cassettes are adjustable on a 50 mm pitch, letting you mix 150 mm SCH40 pipe on level one, 90 mm solid round on level two, and 200 × 100 mm rectangular tube on level three. Load dividers slide sideways so a single cassette can grip one 12 m bundle or three 4 m bundles without tie-wrapping. Divider faces are nylon-faced to protect polished architectural bronze; optional V-block inserts cradle drill collar threads so shoulder damage disappears from your non-conformance log.

The control ecosystem is brand-agnostic. Default PLC is Siemens S7-1500 with PROFINET, yet we will ship Allen-Bradley, Mitsubishi, or Beckhoff if your standardisation plan demands it. The WMS talks SQL, OPC-UA and REST; therefore SAP, Oracle, Infor or a home-grown MES can reserve, release and decrement inventory in real time. A web dashboard shows heat-map utilisation, expected empty time, and remnant ageing so purchasing can cut emergency orders by 18 % on average. If an operator scans a barcode on the saw remnant, the system books it back into the nearest cassette and updates nesting software automatically—no re-keying, no typo, no ghost inventory.

Safety is engineered, not added. The gantry zone is fenced to Category 3 PLd; maintenance gates carry Fortress interlocks that dump servo power and apply motor brakes in <300 ms. A through-beam light grid 600 mm above floor level creates a “safe crawl” zone so operators can retrieve dropped tags without full lockout. Vertical travel is limited by both software cam and mechanical hard-stop; even if a limit switch fails, the carriage hits a polyurethane buffer rated for 150 % of dynamic load. Fire suppression nozzles can be pre-installed at 1.5 m intervals; the control cabinet already reserves 24 VDC outputs monitored by the FM-200 panel.

Energy consumption is modest: 4 kW during lift, 0.8 kW during idle, and <45 W standby thanks to servo regeneration that returns lowering energy to the DC bus. Compare that with a 5 t forklift that idles at 3.5 L diesel per hour and demands a driver every shift. Over five years the Herochu system typically saves 28,000 L of fuel and 74 t of CO₂ even before you count the labour redeployment.

Installation is treated like a project, not a crate. Our engineers visit for a three-day laser survey, verifying floor flatness, crack patterns and seismic joint gaps. Anchor bolts are Hilti HDA-P 20 × 170 mm, torque-monitored and logged. After mechanical completion we run a 1.2 × rated load static test and 1 × dynamic test for two hours; certificates are handed over during operator training. Your maintenance team receives a digital twin on USB: every sensor, every bearing, every spare part code clickable in 3-D so downtime never waits on a faxed manual.