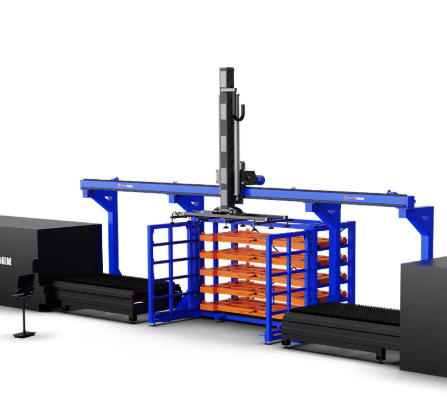

Revolutionizing Laser Cutting Operations with Herochu’s Automated Material Handling System

Introduction to Next-Generation Workshop Automation

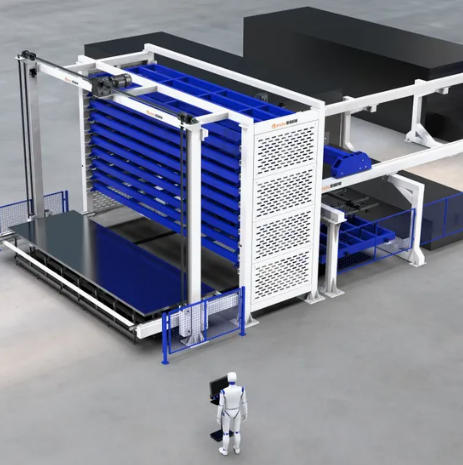

In today’s competitive manufacturing landscape, the Herochu Automatic Loading and Unloading System for CNC Fiber Laser Cutters represents a quantum leap in operational efficiency. Engineered for workshops demanding precision and productivity, this CE/EU/ISO 9001-certified solution transforms raw material handling from a labor-intensive bottleneck into a seamless automated process. Starting at just $8,900 with full customization capabilities, our system delivers measurable ROI through intelligent automation.

Core Technical Specifications

Dimensional Flexibility & Structural Integrity

- Model Range: 3015/4015/4020/6015/6020/6025mm configurations

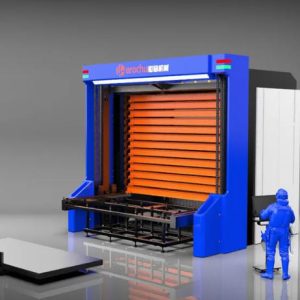

- Multi-Tier Storage: 8-13 floor capacity with 3T/5T load per layer options

- Movement System: Linear guide rail + chain drive combination

- Operational Speeds:

- Vertical lifting: 9m/min

- Inlet/outlet: 12m/min

- Plate Support: Customizable configurations for diverse material profiles

Engineering Excellence in Material Handling

Precision Movement Architecture

The system’s dual transmission mechanism combines the accuracy of linear guide rails with the durability of chain drives, achieving positional accuracy within ±0.1mm. This hybrid approach eliminates vibration during high-speed transfers, critical for maintaining cut quality in sensitive applications.

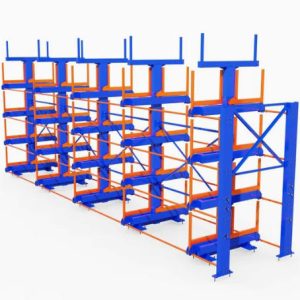

Smart Storage Solutions

Our multi-level storage units aren’t just space-savers—they’re intelligent material buffers. The cantilevered shelf design prevents sheet deformation while allowing:

- FIFO/LIFO inventory management

- Automated thickness detection

- RFID-enabled material tracking (optional)

Automation Features That Redefine Productivity

Vacuum Handling Technology

The independent vacuum loading system features:

- Zone-controlled suction for mixed material sizes

- Fail-safe pressure monitoring

- Energy-saving pulse cleaning cycles

- <5 second sheet acquisition time

Seamless Production Integration

- EtherCAT Bus Communication: Real-time synchronization with laser cutters

- Forklift Coupling Interface: Emergency manual loading protocol

- Priority Order Override: Dynamic job queue management

Operational Advantages for Modern Workshops

Labor Optimization

Reduce staffing requirements by 60-80% for material handling tasks. The system’s autonomous operation continues through shift changes and breaks, delivering 22.5 productive hours/day (vs. 16-18 with manual handling).

Throughput Enhancement

Case studies demonstrate:

- 45% reduction in cycle time

- 30% increase in machine utilization

- 15% improvement in sheet yield through optimized nesting

Safety & Compliance

- CE-certified emergency stop circuits

- Light curtain protection zones

- ISO 13849-1 PLd safety rating

- Automated scrap ejection channels

Smart Manufacturing Connectivity

The system serves as a material handling hub within Industry 4.0 environments, offering:

- OPC UA interface for ERP integration

- Predictive maintenance alerts

- Energy consumption analytics

- Remote diagnostics via VPN

Customization for Specialized Applications

Material-Specific Configurations

- Stainless steel anti-scratch coatings

- Non-ferrous material handling packages

- Composite material adapters

- High-reflectivity surface protocols

Workshop Integration Services

Our engineering team provides:

- Laser cutter interface programming

- Facility layout optimization

- Operator training packages

- Annual maintenance contracts

Comparative Performance Data

| Metric | Manual Handling | Herochu System | Improvement |

|---|---|---|---|

| Daily Throughput | 85 sheets | 132 sheets | +55% |

| Setup Time | 18 minutes | 3.5 minutes | -80% |

| Material Damage | 2.1% | 0.3% | -86% |

| Energy Use | 11.2kWh | 8.7kWh | -22% |

Why Global Manufacturers Choose Herochu

- Proven Reliability: 98.7% uptime across 240+ installations

- Future-Proof Design: Field-upgradable to AI vision systems

- Localized Support: 48hr response guarantee in NA/EU markets

- Sustainable Engineering: 92% recyclable components

Implementation Roadmap

- Needs Assessment (1-3 days)

- Custom Engineering (2-4 weeks)

- Factory Acceptance Testing (1 week)

- Onsite Installation (3-5 days)

- Productivity Benchmarking (ongoing)

Total Cost of Ownership Breakdown

- Initial Investment: $8,900+

- Annual Maintenance: $1,200-$2,500

- Energy Savings: $3,800+/year (vs. manual)

- Labor Savings: $45,000+/year (per shift)