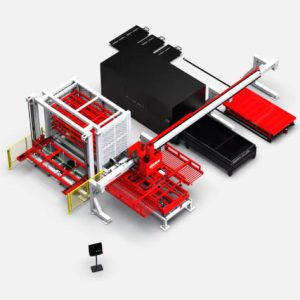

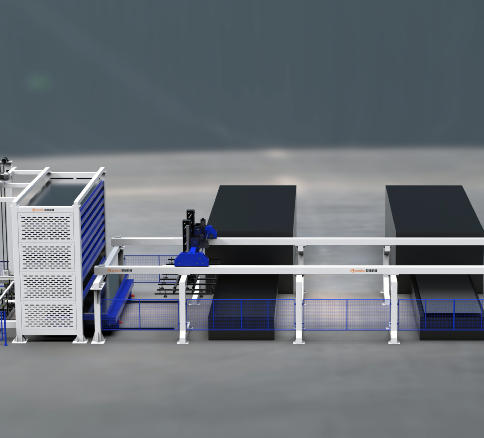

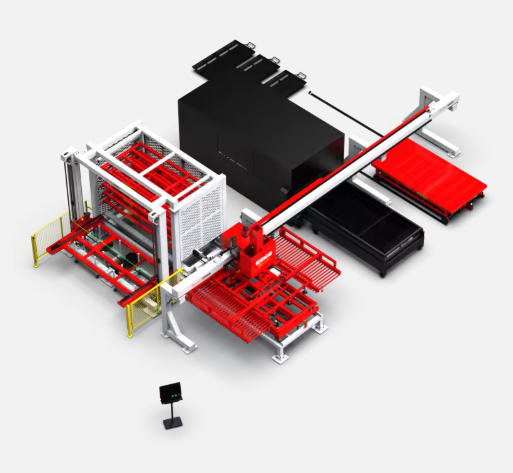

Herochu Automatic Loading and Unloading Systems for Fiber Laser Cutter

Custom-configured to fit your workshop from USD 20,200

CE • UE • ISO 9001 certified

Sheet-metal manufacturers who still rely on forklifts, magnets and manual stacking already know the hidden costs: scratched surfaces, inconsistent pallet heights, overtime premiums and the constant risk of laser-idle minutes. The Herochu Automatic Loading and Unloading System for Fiber Laser Cutter eliminates every one of those pain points by synchronising material flow, cutting performance and finished-part handling in a single, compact line.

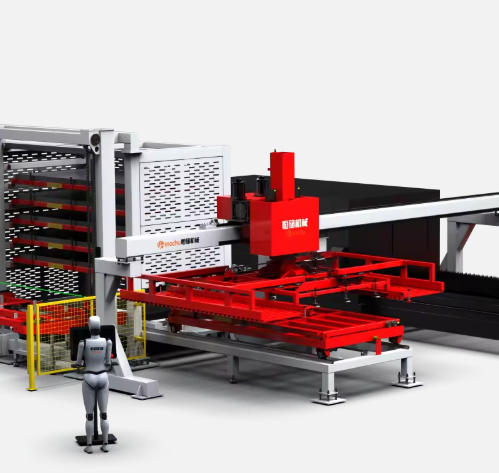

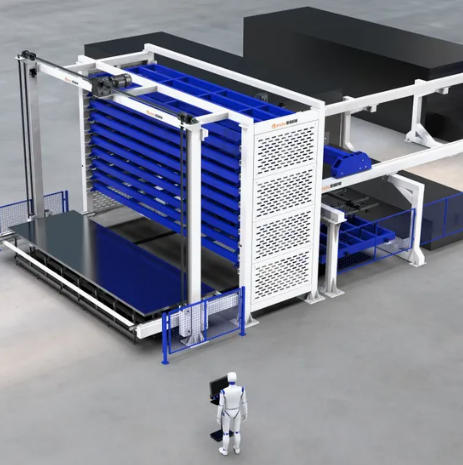

A complete line, not an accessory

Unlike retrofits that bolt awkward arms to an existing table, Herochu delivers a purpose-built architecture. A heavy-duty storage tower—height and rack count chosen by you—feeds sheets to the cutting bed through a dual-servo shuttle. Once the fiber laser completes the nest, an unloading gantry lifts the finished parts and skeleton onto separate pallets while a fresh sheet is already in motion. The result is an uninterrupted rhythm: 110 seconds end-to-end for a standard 1.5 m × 3 m plate, including micro-tab removal and label placement.

Radiation-safe, operator-friendly envelope

European safety directives are not an afterthought. The full perimeter housing uses laser-rated polycarbonate panels and interlocked access gates that cut beam power the moment any panel is opened. Inside, LED strip lighting gives operators clear sightlines for consumable checks, while integrated fume extraction keeps the workspace free of zinc oxide and chromium vapours. The envelope also shields mechanical components from accidental impact—an everyday occurrence in busy job shops—extending cable and actuator life by up to 40 %.

Intelligent height sensing and pallet management

Each unloading fork carries a non-contact laser distance sensor that records the exact stack height after every drop. When the programmable limit is reached, the HMI flashes green and sends an e-mail to the forklift driver, eliminating the “full pallet surprise” that shuts down the entire shift. The same sensor prevents double-sheet pickup by measuring thickness at the suction cups; if the value deviates from the recipe, the shuttle pauses and alerts maintenance before a crash occurs.

Real-world throughput figures

• 6 kW fiber source, 10 mm stainless: 2.1 m/min average cutting speed—10 % faster than the same laser without automatic handling.

• 3 mm mild steel, 150-part nest: full cycle completed in 7 min 40 s including load/unload.

• 24-hour endurance test: 0.2 % downtime attributed to consumable changes only.

Industry breadth

The system ships with a pre-loaded process library covering 200 grades of carbon steel, stainless, aluminium, brass and copper up to 20 mm. Whether your customer base spans elevator cladding, electrical enclosures, food-service counters or automotive brackets, the same line handles the mix without manual parameter tweaks. Quick-change nozzle and lens cartridges reduce alloy changeover to under two minutes.

Cost profile that finance teams applaud

Nitrogen has become the single largest variable cost in high-volume fibre cutting. Herochu’s proprietary piercing and cutting database lowers nitrogen consumption by up to 40 % on 6–12 mm stainless. In practical terms, cutting a 10 mm stainless part that once cost USD 0.18 in gas now costs USD 0.11. Over a typical 2,000-hour production year, that saving alone funds the depreciation of the entire handling system.

Floor space and scalability

Customers often assume automation demands an additional bay. In reality, the standard tower and shuttle assembly occupies 6.2 m × 3.5 m—less floor area than two manual pallet positions plus the forklift aisle they replace. Should volumes grow, extra tower modules bolt on in 1.5 m increments without moving the laser. Retrofit downtime is measured in hours, not weeks.

Maintenance designed for uptime

All linear axes ride on sealed linear guides with automatic oil-pulse lubrication; service intervals are 1,000 hours. Vacuum cups, gripper fingers and bellows are classified as wear items and stocked in regional service vans for same-day replacement. Remote diagnostics via secure VPN allow Herochu engineers to view PLC and servo data in real time, resolving 82 % of alarms without an on-site visit.

Deployment roadmap

- Site survey—laser model, sheet sizes, incoming material flow and ceiling height recorded in CAD.

- Custom proposal—tower height, rack count, unloading zone layout and safety fencing defined.

- Factory acceptance—customer witnesses full-speed cycle on their actual material mix.

- Installation and commissioning—three-day mechanical fit, one-day calibration, one-day operator training.

- Performance guarantee—throughput and availability KPIs written into the purchase contract.

Conclusion

The Herochu Automatic Loading and Unloading System for Fiber Laser Cutter turns the most labour-intensive step in sheet-metal fabrication into a silent, repeatable process. With CE, UE and ISO 9001 certification, guaranteed cycle times and total cost of ownership that beats manual handling within twelve months, the decision is no longer whether to automate, but how soon the line can be commissioned. Request your customised quotation today and reclaim the profit hidden in every sheet.