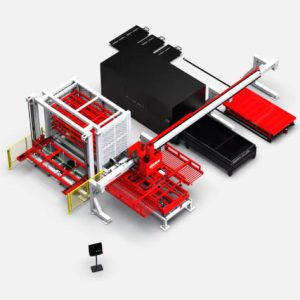

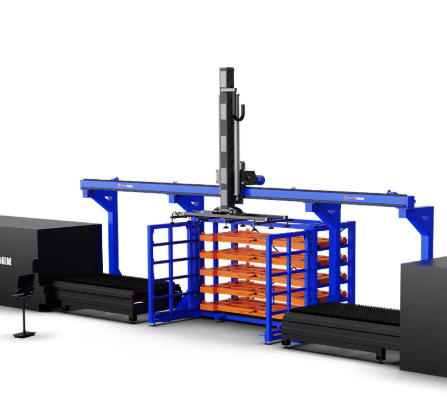

Herochu Automatic Loading & Unloading Laser Cutting Machine with Warehousing System

Revolutionize Your Metal Cutting Operations

The Herochu Automatic Loading & Unloading System for Fiber Laser Cutting Machines is engineered to maximize productivity, minimize downtime, and deliver unparalleled precision in metal fabrication. Certified under CE, UE, and ISO 9001 standards, this system integrates seamlessly with your existing setup, offering a fully automated solution that adapts to your workshop’s unique requirements.

Key Features & Benefits

- Lightning-Fast Loading & Unloading

- Achieve continuous loading in as little as 110 seconds, significantly reducing idle time.

- Cutting speeds for 10mm stainless steel are 10% faster than conventional methods, doubling throughput without compromising quality.

- Smart Warehousing Integration

- Customizable storage solutions allow for batch processing of sheets, eliminating manual intervention.

- Real-time height detection and intelligent alerts notify operators when material pallets are full, ensuring uninterrupted production.

- Versatile Cutting Capabilities

- Effortlessly process a wide range of metals, including stainless steel, aluminum, carbon steel, and copper.

- Ideal for precision cuts, complex shapes, and high-volume orders.

- Enhanced Safety & Durability

- A large protective enclosure shields operators from harmful radiation and prevents mechanical damage.

- Built for 24/7 operation with minimal maintenance requirements.

- Cost-Effective & Eco-Friendly

- Cutting costs are 90% lower than nitrogen-based methods, reducing operational expenses.

- Optimized material usage ensures near-zero waste, aligning with sustainable manufacturing practices.

Industry Applications

The Herochu system is trusted by professionals across multiple sectors, including:

- Automotive Parts & Aerospace

- Electrical Cabinets & Elevator Manufacturing

- Kitchen Equipment & HVAC Systems

- Advertising & Signage Production

- Sheet Metal Fabrication & Precision Engineering

Why Choose Herochu?

- Customizable Solutions: Tailored to fit your workshop layout and production demands.

- Proven Reliability: Engineered for long-term stability under heavy workloads.

- Competitive Pricing: Starting at $20,200, delivering rapid ROI through efficiency gains.

Transform your metal cutting operations today with Herochu’s Automated Laser Cutting System—where innovation meets industrial excellence.