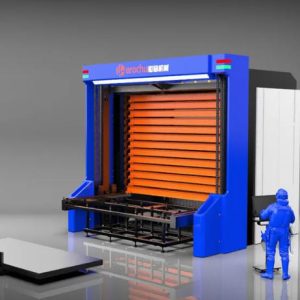

Herochu Automatic Warehouses for Sheets and Panels

From $19,998 – CE/UE/ISO 9001 – engineered for factories that never want to hunt for the right plate again.

Sheet metal stock is money lying flat. Every time a forklift shifts a stillage to reach another bundle underneath, the clock runs, the edges scratch, and the remnant you knew was “somewhere in the corner” disappears. Herochu automatic warehouses turn that chaos into a single vertical cabinet where every plate—full sheet or off-cut—has an address, a weight, and a time-stamp. Towers start at USD 19,998, expand bay by bay, and plug straight into your laser, punch, shear or panel bender so you can run first-shift orders at midnight without turning the lights on.

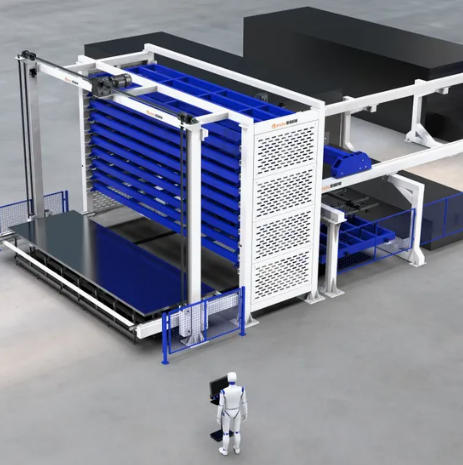

1. Store More in the Same Roof

A two-tower starter unit 6 m high, 3 m wide, stores 180 t of steel, stainless or aluminum in shelves only 120 mm thick. That is the same capacity as 1,200 m² of traditional block-stacking, yet the footprint is 28 m²—less than two parking spaces. Need more? Add another tower overnight; the rail and software simply extend. Heights up to 12 m are shipped pre-welded, so you gain cubic metres without civil work or mezzanine steel.

Shelves accept 3015, 4015, 4020, 6015, 6020 or 6025 mm lengths, but the frame is drilled on a 50 mm grid. If tomorrow you win a contract for 2,500 mm door skins, the shelves move in under thirty minutes and the PLC learns the new positions through a single teach command. Load per shelf is 3 t or 5 t—your choice—tested at 1.4 times rated capacity with a calibrated water-bag rig in our Jiangsu works. The test certificate travels with the machine.

2. Built for Sheet-Metal Reality, Not for Brochures

Columns are 8 mm folded plate, laser-welded, then milled top and bottom so the lift carriage runs within ±0.5 mm over 12 m. Linear guides are 45 mm hardened rail, sealed against grinding dust; bearings are lubricated for 20,000 km—about eight years of two-shift operation. Chain is 16B-2 nickel-plated, pre-stretched to half the ISO wear limit before it leaves the factory. The lift motor is a 3 kW servo with absolute encoder, so if power fails the PLC knows exactly where the carriage stands and no re-reference is needed when power returns.

Every shelf fork is fitted with a 200 mm wide replaceable polymer strip; no steel touches the sheet, so even mirror-polished stainless leaves the tower without a mark. Optional copper bars earth the carriage to prevent galvanic staining on expensive alloys.

3. Remnant Logic That Pays for the Machine

After the nest releases the part轮廓, the remaining sheet is often too small for the next full order but too large to scrap. The Herochu tower asks the operator only one question: “Keep or scrap?” If he taps “Keep,” the system weighs the plate through load cells built into the forks, records the new mass, and assigns it to a virtual remnant stack. Next time the scheduler calls for 2 mm mild-steel 1,500 × 800 mm, the software offers the matching remnant first. Customers report 6 % material savings in the first twelve months—on a 2,000 t/year laser park that is 120 t saved, roughly USD 120,000 at today’s prices.

4. Fewer Forklifts, More Air Time

Traditional stores need a forklift to dig, lift, drive, and place. The Herochu tower needs one forklift only when a new pack arrives from the slitter. After that, everything moves on the built-in shuttle: 12 m/min in and out, 9 m/min up and down. A typical shift at a Dutch white-goods factory dropped from 76 forklift movements to 9. Accident insurance premiums fell 18 % the next policy year, and the fleet lease returned two trucks early, saving another USD 1,100 per month.

5. Plug Into Any Machine, Any Era

The tower speaks plain TCP/IP. If your laser is new, the handshake is Euromap 67; if it is twenty years old and has only 24 V I/O, we add a relay module. No middleware, no annual software tithe. A single Ethernet cable carries:

- Sheet call-off

- Remnant return

- Weight confirmation

- Cutting program number

- Job complete signal

When the scheduler releases a nest, the laser asks the tower for sheet 3 mm 304 stainless 1,500 × 3,000 mm. The tower brings it, records tare, and opens the light curtain. After cutting, the laser sends “job done” and the carriage takes back the skeleton. All of this happens while the operator is deburring the previous job—no extra labour, no barcode scanning, no typing.

6. Developed in the Factory, Proven on the Floor

Every new function—vacuum cup spacing, fork chamfer, chain tensioner—runs 10,000 cycles on our test rig before it is released. We either do it right or we do not do it at all. That motto is stamped on the beam above the exit door, and it is why the warranty is twenty-four months on mechanics, lifetime on structural welds. Service is handled by our own crews, not by an agent whose phone rings busy. A VPN module inside the panel lets us log in within minutes, read the fault, and often email the fix before your maintenance manager finishes his coffee.

7. Safety That Satisfies Insurers

Vertical light curtains stop lift motion if anyone reaches into the aisle. Floor-level photo-eyes prevent shuttle launch when a foot is inside the bay. Each tower has a trapped-key interlock—remove the key and the carriage is mechanically locked. Over-speed governor and hydraulic buffer stop a full 5 t drop without deformation. The entire frame is earthed to EN 60204-1; resistance <0.1 Ω. If you handle titanium or magnesium, we fit ATEX-rated sensors and copper earthing bars. Documentation travels with the machine: risk assessment, conformity declaration, test videos, and torque certificates for every bolt.

8. Sizes That Fit Today, Grows With Tomorrow

- Widths: 3015, 4015, 4020, 6015, 6020, 6025 mm (others on request)

- Heights: 4 m to 12 m in 500 mm steps

- Shelf pitch: 120 mm standard, 75 mm for thin aluminium decks

- Load: 3 t or 5 t per shelf, mixed in the same tower

- Speeds: 9 m/min lift, 12 m/min shuttle

- Accuracy: ±1 mm repeatability at fork tip

- Temperature: −10 °C to +55 °C standard, −30 °C freezer version available

Add another tower next year and the software simply recognises the new address range. No re-licensing, no hardware swap.

9. Options That Make Money, Not Noise

- Integrated weighing: 0.1 % accuracy, uploads tare to MES for coil-to-part traceability.

- Copper earth kit: for titanium, Inconel, or any alloy that fears ferrous spark.

- LED aisle projector: shows next sheet size on the floor so the forklift driver drops the new pack on the correct shelf first time.

- Remnant roller: 1 m powered section flips small blanks back into the tower for night-shift kitting.

- Cladding kit: insulated panels maintain 18 °C and <60 % RH for laser-room climate control, reducing condensation on cold-rolled stock.

10. Ordering Path

- Email a sketch: sheet sizes, max pack weight, ceiling height, aisle width.

- Receive 3-D PDF, cycle-time report, and firm quote within 48 h.

- Approve drawing; 30 % deposit starts fabrication.

- System ships in 6–8 weeks; Herochu technician flies in for commissioning and operator training.

- Balance 70 % after signed acceptance; 24-month warranty begins.

Stop losing hours hunting plates, stop losing money on damaged stock, and stop losing sleep over tomorrow’s schedule. The Herochu automatic warehouse keeps every sheet under control, ready when the laser calls, and accounted for when the accountant asks. Fill the towers, empty the aisles, and let the forklifts collect dust—your sheet-metal factory just entered the unmanned era.