Herochu Bar and Pipe Racks: Low-Profile Storage & Transportation Solutions for Tight Spaces

For workshops with low ceilings—8 feet, 9 feet, or even less—bar and pipe storage feels like an unsolvable puzzle. Standard racks tower too tall, eating into precious vertical space and leaving gaps that go unused. Bars and pipes end up scattered across floors, stacked in unstable heaps, or crammed into corners where they’re hard to reach. Every time a crew member needs a 1-inch steel pipe or 3-foot aluminum bar, they spend 15+ minutes digging through the mess—delaying jobs, wasting labor, and risking damage to high-value stock. Herochu’s Bar and Pipe Racks eliminate this frustration, offering storage and transportation solutions engineered specifically for low-ceiling environments. Certified to CE, EU, and ISO 9001 standards, these customizable systems start at $3,660, turning cramped workshops into organized, high-efficiency spaces for fabricators, plumbers, and machine shops alike.

The Low-Ceiling Trap: Why Standard Storage Fails

Low ceilings (under 10 feet) don’t just limit headroom—they cripple storage efficiency. Most off-the-shelf bar racks are designed for high-bay facilities, with 18–20-inch gaps between shelves. In an 8-foot ceiling, that means you can only fit 3–4 shelves, leaving half your vertical space unused. The alternative—stacking bars on the floor—creates even bigger problems:

- Wasted Time: A crew member searching for a specific pipe spends 15 minutes per hunt, 8 times a day—losing 2 hours daily, or $12,000 in labor annually at $25/hour.

- Material Damage: Bars rolling around on the floor get dented, scratched, or bent. A single damaged 20-foot steel pipe can cost $50–$100 in scrap.

- Lost Revenue: Rush orders get delayed when the right bar or pipe can’t be found. One Ohio shop owner lost a $500 order because a worker couldn’t locate a ½-inch brass pipe in time— a preventable mistake that damaged his reputation.

- Safety Risks: Unstable piles topple easily, and rolling pipes create trip hazards. A single fall from a rolling bar can cost $10,000+ in workers’ compensation.

“We were stuck between too-tall racks and messy floors,” said a Pennsylvania-based plumber. “I’d walk into the shop and see pipes everywhere—my crew hated it, and I hated wasting money on scrap. Low ceilings felt like a death sentence for organization.” Herochu’s Bar and Pipe Racks fix this by reimagining storage for the spaces other systems ignore.

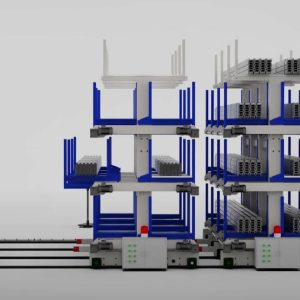

The Herochu Difference: Built for Low Ceilings, Built to Perform

Herochu’s Bar and Pipe Racks are engineered to turn low ceilings from a limitation into an advantage. We don’t force you to adapt to generic storage—we design solutions that fit your space, your stock, and your workflow. The core of our design is a low-profile, high-density system with three game-changing features:

1. Ultra-Low Shelf Clearance for Maximum Layers

Forget 18-inch gaps—our racks use 8-inch shelf spacing to squeeze more storage into tight vertical space. In an 8-foot ceiling, that means 6–7 shelves instead of 3, doubling or tripling your storage capacity without hitting the ceiling. For example, a 6-foot-wide Herochu rack with 7 shelves can hold 21 different bar or pipe types (sorted by material, diameter, and length) in the same footprint as a single floor pile. Each shelf sits just high enough to accommodate even bulky pipe bundles, but low enough to keep every layer accessible—no ladders, no stretching, no wasted space.

2. Roll-Resistant Trays & Guards for Organized Stock

Bars and pipes roll—there’s no getting around it. That’s why every Herochu rack comes with shallow, reinforced trays or side guards on each shelf. Trays cradle round stock to keep it from sliding, while guards prevent pipes from tumbling off when the rack is moved. For a Michigan machine shop with 7.5-foot ceilings, these trays were transformative: “We used to have pipes rolling across the floor every time someone walked by,” the owner said. “Now each pipe has its spot—my crew grabs what they need in 30 seconds, no more chasing rolling metal.”

3. Industrial Strength for Heavy-Duty Use

Bar and pipe stock is heavy: a bundle of 1-inch steel pipes can weigh 1,500+ pounds. Herochu’s racks are built to handle this with 11-gauge steel frames and reinforced shelf decks rated for 2,000–3,000 pounds per level. Unlike flimsy DIY shelves or plastic bins that crack under pressure, our systems stand up to forklift bumps, repeated tray use, and the grit of daily workshop life. The powder-coated finish resists rust and oil, even in damp or messy environments—ensuring the rack lasts for years without needing replacement.

Storage and Transportation: A Two-in-One Solution

Herochu’s Bar and Pipe Racks aren’t just for static storage—they’re designed for easy transportation, a critical feature for workshops that move stock between stations. We offer two transport-friendly configurations:

1. Mobile Pipe & Bar Carts

For shops that need stock near machining or assembly areas, our mobile carts feature heavy-duty casters (lockable for safety) and a low-profile design that fits under low ceilings. A single cart holds 5–8 trays of bars or pipes, rolling directly to lathes, welders, or cutting stations. A Texas fabricator uses three mobile carts: “We used to carry pipes 50 feet across the shop—now we roll the cart right to the plasma cutter. Prep time’s cut in half.”

2. Forklift-Ready Fixed Racks

Fixed racks include forklift pockets or reinforced lifting points, making it easy to move entire shelves of stock without unloading. This is a game-changer for warehouses with low ceilings and limited maneuvering space—no need to disassemble the rack or handle heavy bundles by hand. “We can reposition a full rack in 2 minutes,” said a Florida plumber. “Before, it would take two guys an hour to move the same pipes.”

The Transformation: What Low-Profile Racks Actually Do for Your Shop

When workshops switch to Herochu’s Bar and Pipe Racks, the difference is immediate—measured in time, money, and peace of mind. Take the Pennsylvania plumber with a 8-foot ceiling:

1. Storage Capacity Tripled

A single 6-shelf Herochu rack replaced a 120-square-foot floor pile of pipes. The shop went from storing 50 pipe types to 150, all in the same space. “I used to turn down jobs because I didn’t have room for stock,” the owner said. “Now I can take on more work without expanding.”

2. Retrieval Time Cut by 85%

What took 15 minutes now takes 2 minutes. Over a month, that’s 100+ hours of saved labor—equivalent to two and a half full workweeks. The crew reallocated that time to billable work, increasing monthly revenue by 12%.

3. Material Waste Dropped by 20%

Pipes and bars are no longer dented, bent, or lost. The shop’s scrap rate fell from 10% to 2%, saving $1,600 in material costs in the first three months. “I used to write off $50 worth of damaged pipe every week,” the owner noted. “Now it’s rare.”

4. Floor Space Reclaimed by 35%

Clearing floor piles opened up room for a new workbench and a safer forklift path. The shop’s accident rate dropped to zero, and OSHA inspections became stress-free. “The inspector commented on how organized we were—something that never happened before,” the safety manager said.

5. Inventory Management Simplified

Labeled shelves sync with the shop’s inventory software, turning 4-hour cycle counts into 30-minute tasks. Low stock is spotted instantly, so the shop no longer runs out of critical pipes mid-job. “We used to overstock to avoid shortages,” the owner explained. “Now we order exactly what we need, freeing up $3,000 in working capital.”

Why Herochu’s Racks Stand Out for Low-Ceiling Shops

In a market full of generic storage, Herochu’s Bar and Pipe Racks are built for the unique challenges of tight spaces. Here’s what sets us apart:

- Customization for Your Ceiling: We design shelf heights (6–10 inches) and rack widths (3–8 feet) to fit your exact ceiling clearance and floor space. Got a 7-foot ceiling? We’ll build a 5-shelf rack that maximizes every inch.

- Dual Purpose: Store & Transport: No need for separate storage and carts—our racks work for both, saving you money and space.

- Certified Durability: CE, EU, and ISO 9001 certifications mean our racks meet global safety standards. This isn’t cheap shelving—it’s an investment that pays for itself.

- Fast ROI: Starting at $3,660, most shops recoup costs in 4–6 months through labor and material savings. The Pennsylvania plumber hit ROI in 5 months and called it “the best shop upgrade I’ve ever made.”

Your Turn: Stop Wasting Space in Your Low-Ceiling Shop

If your bars and pipes are taking over the floor, your crew is wasting hours searching, and your low ceiling feels like a dead end—you’re leaving money on the table. Herochu’s Bar and Pipe Racks turn cramped spaces into organized, efficient hubs. We’ll measure your ceiling, assess your stock, and design a system that fits your workflow—no guesswork, no wasted money.

Imagine: A clear floor, bars and pipes in labeled trays, and a crew that spends more time working than hunting. That’s what Herochu’s storage and transportation solutions deliver.

Ready to make the most of your low-ceiling workshop? Contact Herochu today to schedule a free space assessment and design your custom Bar and Pipe Rack system.