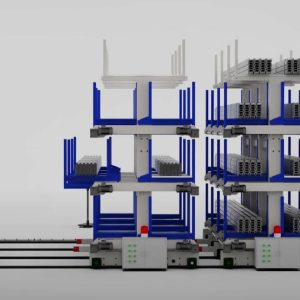

Herochu Cantilever Racking for Long Goods Storage – CE-Certified Steel That Turns Pipe, Bar and Timber into a Measurable Asset

Every metre of floor you save is a metre you do not have to heat, light or insure. Herochu Cantilever Racking for Long Goods Storage is built for managers who treat square footage like cash in the bank. Hot-rolled IPE uprights, bolted taper arms and machined base plates are welded under ISO 9001 surveillance, shot-blast to SA 2.5 and finished with zinc primer plus 80 µm polyester topcoat. The result is a storage structure that carries a 25-year design life yet pays for itself in eighteen months through reclaimed aisle width, faster cycle counts and the insurance premium reduction that arrives the day you present the CE Declaration of Performance.

One rack, any length, any load

Choose single- or double-sided configurations from 2 m to 12 m high. Arms project 600 mm, 800 mm, 1 000 mm, 1 200 mm or 1 500 mm and carry 800 kg to 4 000 kg each when evenly loaded. Need to store 14 m glulam beams or 40 ft drill pipe? Bolt two bays together and insert a 3 mm reinforcing plate—no re-engineering, no hot work on site. The arm profile is a closed 4 mm taper section that prevents thin-wall tube from ovalising and stops timber packs from side-slip. A hardened locking pin secures every arm; remove it and the arm drops clear so an overhead crane can lower a 30 t coil straight onto the base rails without jack-leg rigging.

Forklifts drive in, cranes reach over, robots plug in

Traditional stacked timber or nested pipe forces a counter-balance truck to approach at 90°, rear swing protruding into the pedestrian zone. Herochu arms present the load face-on. A telescopic handler drives straight down the 1.4 m aisle, lifts the bundle and exits without slewing. Prefer overhead handling? Weld-on crane lugs rated 5 t are supplied loose; fit them only on the levels you designate so the remaining bays stay flush for forklift work. Planning a six-axis robot or vacuum lifter? We pre-drill a 50 mm conduit hole through the column base plate so sensor cables run under the floor, keeping the workspace trip-free and preserving the clear 100 mm ground clearance demanded by NFPA fire codes.

Numbers that satisfy auditors and accountants

- Column moment capacity: verified to EN 1993-1-1 with γM0 = 1.0

- Arm deflection: ≤ L/200 under rated load—measured and recorded on every test certificate

- Anchor pull-out: 45 kN in C30/37 concrete—tested in-house and witnessed by TÜV

- Galvanised finish: 50 µm zinc layer to EN ISO 1461—salt-spray 1 000 h no red rust

- Design life: 25 years in internal ambient conditions; 15 years coastal with six-month wash-down schedule

Present these figures to your insurer and expect a 5–15 % reduction in public-liability premium—documented case studies from Aberdeen, Rotterdam and Houston are available on request.

Installation that respects production windows

Herochu racks ship as pre-bolted portal frames 2.4 m wide. Two technicians and a scissor lift can anchor an eight-bay run in one shift; no on-site welding means no hot-work permit, no fire watch, no line shutdown. Once the first frames are level and anchored you can load material immediately; additional bays bolt on like Meccano during the next weekend window. We provide a laser-level template and a calibrated torque wrench so your maintenance team can replicate factory tightness—no guesswork, no loose connections discovered during the annual audit.

Outdoor rugged, indoor refined

Store 25 t of 12 m drill collar on the quayside? Galvanise after fabrication and receive a full zinc envelope inside the arm slots and outside the plate edges—no un-coated boundaries for salt to attack. Inside a climate-controlled aerospace plant? Specify RAL 7035 powder coat with anti-static additive so carbon-fiber tube is safe from electrical discharge. Need clean-room compliance? Supply us with your particle count limit and we will deliver stainless arms with Ra ≤ 0.4 µm finish and sealed pivot pins.

Real-world ROI snapshot

A Norwegian OCTG processor replaced 480 m² of timber dunnage with 140 m² of Herochu cantilever racking. The freed 340 m² now houses a new CNC threading line that added USD 2.1 M annual revenue. Pay-back on the rack investment: 3.8 months. Insurance premium reduction: USD 18 000 per annum. Forklift impact incidents: zero in the first 18 months.

Specification summary

- Uprights: IPE 270–400 S355, 5 mm flange, 3 mm web, slotted 100 mm pitch

- Arms: 4 mm taper box section, welded end-plate, locking pin included

- Bracing: 50 × 8 mm flat diagonals, bolted M16 8.8, shear 96 kN

- Base plate: 20 mm S355, four M24 anchors, 45 kN shear capacity

- Height: 2 000–12 000 mm in 500 mm increments

- Arm length: 600–1 500 mm, capacity 800–4 000 kg per arm UDL

- Finish: shot-blast SA 2.5, zinc primer 60 µm, topcoat 80 µm or hot-dip galvanised

- Certification: CE marked to EN 1090-1, EXC 2, issued with Declaration of Performance, ISO 9001 mill test reports, TÜV anchor pull-out certificate

Procurement in four steps

- Sketch the longest item, bundle weight and building grid; email the drawing.

- Receive a 3D STEP model, load diagram and fixed-price quotation within 24 h.

- Approve layout; we cut, weld, blast and finish in 25–30 calendar days.

- Delivered in 40 ft HC containers; install and load the same weekend.

Optional extras: column protectors, aisle LED lighting, barcode arm tags, WCS handshake to SAP or Oracle. Finance lease and duty guidance available for overseas buyers.

Stop measuring storage by how much you can stack and start measuring by how quickly you can release it to production. Herochu Cantilever Racking for Long Goods Storage turns pipe, bar, timber and profile into a traceable, insurable, high-density asset—today, next year and the decade after that.