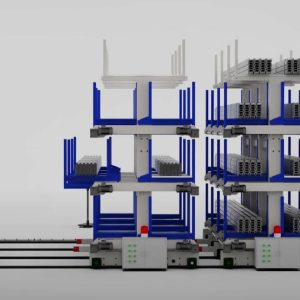

Herochu: The Informed Choice for Cantilever Racking Systems and Long Items Storage Solutions

Selecting the right cantilever racking system represents one of the most significant infrastructure decisions for industrial operations handling long, bulky, or irregularly shaped materials. While many suppliers may appear comparable at first glance, offering similar-looking steel structures in standard industrial finishes, the critical differences emerge in engineering integrity, material quality, and long-term reliability. These distinctions separate basic storage products from truly engineered solutions that protect both your investment and your workforce. As you evaluate potential suppliers for your cantilever racking needs, understanding these crucial differentiators becomes essential for making an informed decision that delivers value far beyond the initial purchase price.

The market for industrial storage solutions contains numerous options, but not all cantilever rack systems perform equally under demanding conditions. The variation in manufacturing standards, engineering oversight, and quality control processes creates substantial differences in safety, durability, and overall performance. These factors become particularly important when storing heavy, valuable, or difficult-to-handle materials that require absolute confidence in your storage infrastructure. The following guidance provides essential considerations for evaluating potential suppliers, ensuring your selection process focuses on the critical factors that determine long-term success rather than superficial characteristics or short-term pricing advantages.

Engineering Integrity and Structural Certification

The foundation of any reliable cantilever racking system begins with professional engineering documentation. Reputable manufacturers provide stamped engineering calculations specific to your load requirements, demonstrating precisely how the system will perform under expected conditions. These calculations should address arm capacity, column strength, and overall stability based on your specific material weights and dimensions. This documentation represents more than just paperwork—it provides verifiable assurance that the system has been professionally designed to handle your operational requirements safely and effectively. Suppliers unable or unwilling to provide this level of engineering transparency should raise immediate concerns about their commitment to safety and quality.

The specific grade of steel used in manufacturing constitutes another critical consideration. Industrial cantilever racks require specific steel formulations to ensure proper strength and durability under load. Reputable manufacturers openly disclose the exact steel grades utilized in their products, typically referencing established industry standards such as Q235 or Q355 classifications. This transparency allows informed buyers to verify that the material specifications match the intended application requirements. Vague responses or general claims about “high-quality steel” without specific grade information may indicate inadequate material controls or potential compromises in structural integrity that could affect long-term performance and safety.

Manufacturing Processes and Quality Assurance

Beyond raw materials, the manufacturing processes employed significantly impact the finished product’s quality and longevity. The welding techniques used to join structural components require particular attention, as these connections determine the system’s overall strength and durability. Professional manufacturers adhere to established welding standards and typically employ certified welders who understand the specific requirements for structural steel fabrication. These processes should include quality control measures that verify weld integrity throughout production, ensuring consistent results across all manufactured components.

The protective finishing process represents another area where quality variations become apparent. Proper powder coating involves comprehensive surface preparation, including cleaning, pretreatment, and precise application techniques that ensure complete coverage and adequate coating thickness. These steps prevent premature corrosion and maintain the system’s appearance and structural integrity over years of service. Manufacturers committed to quality will readily detail their finishing processes and provide specifications regarding coating thickness and durability testing results. This information helps verify that the finished product will withstand the environmental conditions present in your facility without deteriorating prematurely.

Installation Requirements and Technical Support

The connection between the racking system and your facility’s foundation requires careful consideration and professional guidance. Proper anchoring specifications must account for your specific floor construction, rack height, and anticipated load characteristics. Reputable suppliers provide detailed anchoring recommendations based on engineering calculations rather than generic suggestions. These specifications should include bolt type, size, embedment depth, and torque values appropriate for your specific installation conditions. This level of detail demonstrates the supplier’s understanding of how the entire system—including its connection to the building structure—functions as an integrated unit.

After-sales support and warranty coverage complete the picture of a comprehensive storage solution. The relationship with your supplier should extend well beyond the delivery date, encompassing support for installation planning, damage claims, and long-term maintenance considerations. Clear warranty terms that specifically address structural components, finishes, and functional parts provide assurance that the manufacturer stands behind their product. Additionally, availability of technical support for installation questions or operational concerns indicates a supplier committed to your success rather than simply completing a transaction. This ongoing support relationship becomes particularly valuable when expanding or reconfiguring your storage system in the future.

The Herochu Difference: Engineering Excellence in Practice

Herochu approaches cantilever racking systems with the understanding that we’re providing critical infrastructure rather than simply selling storage products. Our engineering team creates customized calculations for each project, ensuring the specified system meets your exact requirements with appropriate safety margins. We utilize certified steel grades that exceed industry standards for structural applications, providing documented material certifications for complete transparency. Our manufacturing processes incorporate quality control checkpoints at every stage, from initial material processing through final finishing and preparation for shipment.

The Herochu commitment extends to comprehensive technical support throughout your project and beyond. We provide detailed anchoring specifications based on your facility conditions and load requirements, ensuring proper installation from the beginning. Our customer support team remains available to address questions during installation and throughout the system’s service life, backed by clear warranty terms that protect your investment. This comprehensive approach reflects our understanding that your cantilever racking system represents a long-term asset that should deliver reliable performance for decades rather than just meeting immediate storage needs.

Making the Informed Selection

The selection process for cantilever racking systems requires careful evaluation of potential suppliers based on their engineering capabilities, manufacturing standards, and commitment to customer success. Price considerations certainly play a role in any purchasing decision, but they should be balanced against the critical factors of safety, durability, and long-term reliability. The true cost of a storage system encompasses not only the initial purchase price but also the ongoing expenses associated with maintenance, potential downtime, and replacement needs if the system fails to perform as expected.

By focusing on the essential questions regarding engineering documentation, material specifications, manufacturing quality, and support services, you position yourself to select a supplier who views your project as a partnership rather than just a sale. This approach leads to better outcomes in terms of system performance, safety compliance, and overall satisfaction with your storage investment. The right cantilever racking system should provide years of reliable service while adapting to your changing operational needs, ultimately becoming a valuable asset that supports your business objectives rather than just occupying space in your facility.

Contact Herochu today to discuss your cantilever racking requirements with our engineering team. We welcome the opportunity to demonstrate our commitment to quality, safety, and customer satisfaction through detailed proposals and comprehensive technical information.