Choosing Sheet Steel Storage Rack: A Guide to Durable, Heavy-Duty Industrial Solutions

For manufacturing plants, construction firms, and warehouses handling bulk sheet materials—from metal and steel to wood and gypsum—selecting the right storage rack isn’t just a purchase; it’s a decision that shapes operational efficiency, material longevity, and long-term cost savings. With storage demands growing yearly, settling for a one-size-fits-all solution can lead to cluttered spaces, damaged inventory, and slow workflows. Herochu’s sheet steel storage racks—customizable to your workshop, starting at $3,660 and backed by CE, EU, and ISO 9001 certifications—address these pain points. This guide breaks down the critical factors to evaluate when choosing a heavy-duty, durable sheet steel storage rack, ensuring you invest in a system that aligns with your needs today and scales with you tomorrow.

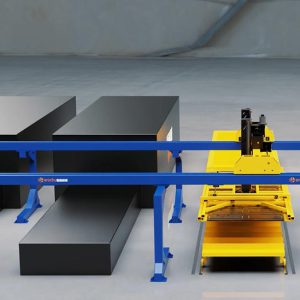

Start with Space Efficiency: Maximize Storage Density Without Sacrificing Access

The first rule of warehouse management is making the most of limited space—and your sheet steel storage rack should be designed to do exactly that. Every facility has unique layout constraints: column spacing, aisle widths, ceiling heights, and footprint limits. A high-quality rack doesn’t just “fit” your space—it transforms it by boosting storage density while keeping materials accessible.

Herochu’s sheet steel storage racks excel here with flexible, adjustable designs. Unlike fixed racks that force you to conform to their dimensions, our systems let you tweak the number of layers (from 2 to 10, with custom options available) and layer capacity (supporting 2T to 5T per layer, with upgrades on demand) to match your material sizes. This means you can store thin aluminum sheets on one layer and thick steel plates on another—no wasted vertical or horizontal space. A warehouse manager at a mid-sized construction firm put it best: “Herochu’s adjustable design let us change layer heights based on what we’re storing that week—we’ve boosted our space utilization by 35% since installing them.”

Modularity is key, too. Our racks adapt to your warehouse’s existing structure, whether you’re working around narrow aisles or low ceilings. No more rearranging your entire facility to fit a rack—we build the rack to fit your layout, ensuring every inch of space works for you.

Prioritize Operational Convenience: Simplify Access to Save Time

Efficiency dies when retrieving a single sheet of steel takes 20 minutes of moving other materials. Traditional stacking or poorly designed racks force teams to waste time on repetitive, non-value-added work—like shifting bundles to reach a bottom layer. The best sheet steel storage racks eliminate this friction by making access fast and intuitive.

Herochu’s horizontal sheet steel racks are built for one-person operation: no need for multi-team lifts or complicated machinery. Each layer features 100% extractable drawers with smooth-rolling wheels—slide a drawer out, grab the sheet you need, and close it back. No moving adjacent materials, no struggling with unsteady stacks. For facilities using cranes, jibs, or vacuum lifters, the design integrates seamlessly: load directly into the drawer, or unload without rearranging the rack. This simplicity cuts retrieval time by up to half, freeing your team to focus on production instead of material handling.

One metalworking shop owner noted: “Before Herochu, two people spent an hour a day just digging for the right steel sheet. Now one person does it in 10 minutes—we’ve reallocated that time to actual manufacturing.”

Protect Your Sheets: Minimize Damage to Preserve Inventory Value

Sheet materials—especially metal, glass, and finished wood—are fragile in storage. Bending, scratching, or edge damage from stacking or friction can render expensive stock unusable, eating into your bottom line. A durable sheet steel storage rack should act as a protector, not just a holder.

Herochu’s horizontal design eliminates the pressure points of vertical stacking. By resting sheets flat on sturdy, powder-coated surfaces, the racks prevent extrusion and friction between layers—no more dented steel edges or scratched aluminum surfaces. The powder coating itself adds another layer of protection: it resists corrosion from moisture or chemicals, keeping both the rack and your sheets in good condition for years. For materials prone to warping, like thin stainless steel, the stable horizontal position ensures they stay flat, avoiding costly rework or replacements.

A fabrication manager summed it up: “We used to lose 5% of our steel sheets to storage damage. With Herochu’s racks? It’s less than 1%. That’s thousands saved every quarter.”

Demand Flexibility & Scalability: Grow With Your Material Needs

Construction and manufacturing don’t stand still—your storage rack shouldn’t either. One month you might be storing 2m wood boards; the next, 6m steel plates. A rigid rack will leave you scrambling to find extra space or buy new equipment. Herochu’s sheet steel storage racks are built for adaptability.

Our modular design lets you reconfigure layers, adjust heights (from 50mm to 200mm between layers), or add new sections as your inventory changes. Need to switch from storing metal sheets to gypsum boards? Simply adjust the layer spacing—no tools, no downtime. And if you expand your workshop or relocate, the racks are detachable and stackable, so you can take your storage system with you instead of starting over. This scalability means your initial investment keeps working for you, even as your business grows.

Herochu’s racks, certified to CE, EU, and ISO 9001 standards, are built to last—their high-strength iron and carbon steel construction resists wear, even in high-traffic industrial environments. This durability means fewer repairs, longer lifespans, and consistent performance. Plus, the time saved on material handling and the reduction in damaged stock often cover the initial cost within the first year.

Choose Herochu: A Rack That Works for Your Workshop

When choosing a sheet steel storage rack, don’t just check boxes—invest in a system that solves your unique challenges. Herochu’s customizable, durable, and efficient racks align with every factor in this guide: space efficiency, operational ease, material protection, flexibility, and long-term value. Whether you’re a small fabrication shop or a large construction firm, we’ll tailor the rack to your workshop’s layout, material needs, and budget.

Contact Herochu today to discuss your storage goals and get a personalized quote. With our sheet steel storage racks, you’re not just buying storage—you’re buying a more efficient, cost-effective, and reliable workshop.