Maximize Vertical Storage: The Definitive Guide to Compact Cantilever Roll Out Racking

In the relentless pursuit of operational efficiency within manufacturing, construction, and logistics, the challenge of storing long, cumbersome materials—pipes, structural steel, timber, and panels—remains a persistent hurdle. Traditional shelving and static racking consume invaluable floor space, create access nightmares, and often lead to damaged inventory and worker inefficiency. For facilities where every square foot counts, a paradigm shift in storage methodology is not a luxury but a necessity. This is the precise problem our engineers at Herochu set out to solve, culminating in the development of our industry-leading Compact Cantilever Roll Out Racking system. This solution embodies a perfect synergy of robust strength, intelligent space conservation, and unparalleled accessibility, redefining what is possible in modern warehouse and workshop storage.

The Engineering Philosophy: Strength Meets Precision

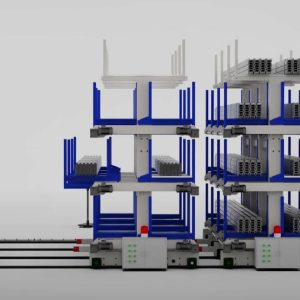

At its core, the Herochu Compact Cantilever Roll Out Racking is a masterclass in practical, heavy-duty design. Constructed entirely from premium ASTM A36 carbon steel, the system is built to endure the most demanding industrial environments. Its architecture consists of rugged upright columns that provide unwavering stability, a fixed base layer for foundational integrity, and the system’s standout feature: fully adjustable telescopic cantilever arms. These arms are the heart of the innovation, engineered to glide smoothly on heavy-duty bearing wheels along a reinforced round tube, all linked to a central transmission frame.

The system’s configuration, typically featuring two movable layers above one fixed base layer, is meticulously designed to exploit vertical space aggressively. This modularity allows for a highly customizable storage profile, ensuring that the racking can be tailored to fit the exact dimensions and load-bearing requirements of your facility, regardless of its size constraints. The entire unit is finished with a durable electrostatic powder coating, not only for superior corrosion resistance but also to offer a professional, clean appearance; our standard blue is iconic, but customization to suit specific facility color schemes is a straightforward process.

Operational Excellence: How It Transforms Workflow

The operational benefits of this system are immediate and profound. The traditional method of retrieving long materials from static racks often requires moving other items, using multiple personnel, or employing complex machinery just to gain access. This is both time-consuming and hazardous. Our telescopic cantilever system eliminates these inefficiencies entirely.

Operation is elegantly simple and intentionally manual for reliability and low maintenance. A worker turns the ergonomic crank handle attached to the transmission frame. This action engages a chain drive system that smoothly extends the entire arm assembly out from the main structure, bringing the stored materials directly into the operating aisle. This “bring-the-storage-to-the-worker” principle means that overhead cranes or hoists can now operate with maximum efficiency, placing or retrieving items with pinpoint accuracy without any obstructions. Once the task is complete, a reverse turn of the crank retracts the arms seamlessly back into the compact, space-saving position. With a formidable load capacity of 4,400 lbs per layer, this system provides Herculean strength in a remarkably compact footprint, making it an ideal cantilever roll out racking solution for spaces where power-operated systems are impractical or unnecessary.

Tangible Benefits for Your Business

Investing in Herochu’s Cantilever Racking system delivers a rapid return on investment through multiple channels:

- Radical Space Optimization: The system’s defining characteristic is its compact nature. When retracted, it requires minimal aisle space, allowing facilities to store more material in the same area or free up floor space for other critical operations. This density directly translates to increased storage capacity without the need for physical expansion.

- Enhanced Safety and Material Integrity: By eliminating the need for workers to climb over or reach through stacks of material to access items buried at the back, the risk of workplace accidents is significantly reduced. Furthermore, materials are stored securely on dedicated arms, preventing the scratching, bending, and warping that often occurs in disorganized piles.

- Dramatic Productivity Gains: Material handling times are slashed. What used to take minutes of maneuvering now takes seconds of cranking. This efficiency allows your team to complete more jobs faster, reducing labor costs and increasing overall throughput. The logical organization also simplifies inventory management and cycle counting.

- Unmatched Durability and Certification: We stand behind the quality of our products. Every component is manufactured under strict quality control protocols and the entire system is CE, EU, and ISO 9001 certified, guaranteeing that it meets the highest international standards for safety and performance.

A Solution Designed for Your Reality

We understand that no two facilities are identical. That is why our Compact Cantilever Roll Out Racking is fully customizable to your workshop. From overall dimensions and arm lengths to load capacities and finish color, our engineering team can adapt the design to your specific needs, ensuring a perfect fit and optimal functionality. With a starting investment of $3,660, this system represents a cost-effective and transformative upgrade to your material handling processes.

Packaging and Support

To ensure your system arrives in perfect condition, it is expertly disassembled into key components. These are carefully wrapped in protective film, organized, and securely mounted on custom-fabricated pallets for safe and efficient shipping across North America. Clear assembly instructions are provided, and our support team is available to ensure a smooth installation process.

If your operation is constrained by inefficient storage for long materials, the Herochu Compact Cantilever Roll Out Racking system is the definitive solution. It is more than just racking; it is a strategic tool designed to enhance safety, drive productivity, and unlock the full potential of your available space.

Contact Herochu today to speak with a storage specialist and begin the process of customizing a system that will transform your workspace.