Herochu Heavy Duty Forklift Sheet Metal Storage Racks: Industrial-Grade Efficiency & Safety

In sheet metal processing facilities, manufacturing plants, and high-volume warehouses, the gap between storage and production efficiency often starts with how heavy sheet stock is handled. Traditional pallets and basic racks force teams into slow, manual workflows—wasting hours moving materials to laser cutters, plasma machines, or bending stations—while exposing workers to injury risks from slipping sheets and overexertion. Worse, these outdated solutions fail to protect valuable metal stock from damage, eating into profit margins. Herochu’s Heavy Duty Forklift Sheet Metal Storage Racks eliminate these bottlenecks, offering a rugged, forklift-integrated system built for the demands of heavy-duty industrial use. Certified to CE, EU, and ISO 9001 standards, these customizable racks deliver safety, efficiency, and long-term value—starting at $3,660.

The Shortcomings of Traditional Storage (And How Herochu Fixes Them)

Traditional storage methods like basic pallets or generic racks were never designed for the unique challenges of heavy sheet metal. Pallets let sheets shift, sag, or scrape against each other during transport, leading to costly scratches or warping. Manual loading and unloading require teams to lift or maneuver heavy stock by hand, increasing the risk of strains, falls, or crush injuries. Even standard racks often lack the structural strength to support dense materials like steel or copper, limiting load capacity to far below what modern facilities need.

Herochu’s Heavy Duty Forklift Sheet Metal Storage Racks address these flaws at every level. Engineered specifically for forklift compatibility, the racks let operators load, unload, and move full sheets or pallets directly—no manual lifting required. The reinforced frame design supports up to 5000 kg per unit, handling even the heaviest industrial sheet stock without bending or instability. And with a focus on material protection, the racks’ secure pallet guides and non-slip surfaces keep sheets in place during transport and storage, reducing waste from damage.

Built for Forklift Integration: Efficiency at Every Step

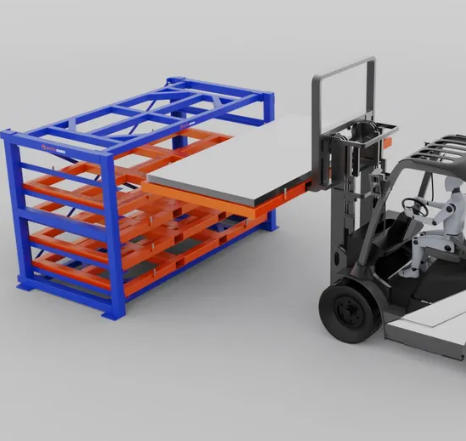

The defining advantage of Herochu’s Heavy Duty Forklift Sheet Metal Storage Racks is their seamless compatibility with standard industrial forklifts—a feature that transforms warehouse workflows. Here’s how it streamlines operations:

Direct Loading/Unloading to Production Lines

Forklift operators can pick up full pallets of sheet metal from the rack and transport them directly to laser cutting, plasma processing, or bending machines. There’s no need for intermediate handling (like transferring sheets to carts or manually feeding machines), cutting workflow time by 40% or more. For facilities running multiple shifts, this efficiency translates to higher daily output and faster order fulfillment.

Dual-Side Access for Flexible Maneuvering

Unlike single-entry racks that trap operators in tight spaces, Herochu’s design offers dual-side access. Forklifts can approach the rack from either side, making it easy to navigate busy warehouses or tight layouts. This flexibility is especially valuable for facilities with overlapping workflows—such as loading raw materials on one side and retrieving processed sheets on the other—without causing bottlenecks.

Pallet-Secure Design for Safe Transport

The racks feature integrated pallet guides and locking tabs that keep pallets stable during forklift movement. This eliminates the risk of sheets slipping off pallets mid-transport, which not only protects materials but also prevents workplace accidents. Even when moving full 5000 kg loads, operators can work with confidence knowing the rack and pallet system are engineered for stability.

Heavy-Duty Strength: Materials & Load Capacity

Herochu doesn’t cut corners on durability. Each Heavy Duty Forklift Sheet Metal Storage Rack is constructed from high-grade structural steel, chosen for its tensile strength and resistance to wear. The frame undergoes precision welding and quality checks to ensure every joint can withstand repeated forklift use and heavy loads. For facilities in harsh environments (like those handling corrosive metals or working outdoors), optional zinc plating or powder coating adds an extra layer of corrosion protection, extending the rack’s lifespan to 10+ years.

The load capacity is where these racks truly stand out. Each unit supports up to 5000 kg—enough to hold stacks of thick steel plates, dense copper sheets, or heavy aluminum stock. The multi-layer design maximizes vertical space, with adjustable shelf heights (from 400mm to 1.5m) to fit different sheet thicknesses. A standard 4-layer rack can store up to 20,000 kg of sheet metal while occupying a footprint of just 1.5m x 3m—freeing up floor space for other equipment or operations.

Safety Features: Protecting Your Team & Materials

Safety is non-negotiable in industrial settings, and Herochu’s racks are built with this in mind:

- Overload Indicators: Optional built-in indicators alert operators if a layer exceeds its weight capacity, preventing structural damage and accidents.

- Anti-Slip Shelves: Textured shelf surfaces keep sheets from sliding, even during facility vibrations or forklift movement.

- Rounded Edges: All frame edges are rounded to reduce the risk of cuts or scrapes when operators work near the rack.

- Stabilized Base: The wide, weighted base prevents tipping, even when loading heavy pallets from one side.

These features don’t just keep teams safe—they also reduce workers’ compensation claims and material loss, contributing to a stronger bottom line.

Customizable to Your Workshop: No More One-Size-Fits-All

Herochu understands that every workshop has unique needs. That’s why the Heavy Duty Forklift Sheet Metal Storage Racks are fully customizable. Whether you need a specific height to fit your warehouse ceiling, wider shelves to accommodate 6m sheets, or a corner-friendly design to fit an irregular space, our team tailors the rack to your layout. We also offer optional add-ons like:

- Label Holders: For easy inventory tracking of different sheet types or sizes.

- Wheel Kits: For mobile racks that can be moved to production lines as needed.

- Weatherproof Covers: For outdoor storage or facilities with high humidity.

The customization process is straightforward: share your workshop dimensions, sheet sizes, forklift type, and load requirements, and our team creates a 3D blueprint of your tailored rack before production begins. This ensures the final product fits perfectly with your existing equipment and workflows.

Industries We Serve: Where Heavy-Duty Racks Deliver Results

Herochu’s Heavy Duty Forklift Sheet Metal Storage Racks are trusted by industries across Europe and beyond:

- Metal Fabrication: Storing pre-cut steel and aluminum sheets, with direct forklift access to laser cutting machines.

- Automotive Manufacturing: Holding structural steel sheets for car bodies, with fast transport to assembly lines.

- Construction: Housing heavy galvanized steel or copper sheets, with dual-side access for quick loading onto trucks.

- Aerospace: Storing thick aluminum and titanium sheets, with secure pallet design to prevent surface damage.

- Logistics Warehouses: Consolidating bulk sheet metal shipments, with high-density storage to reduce rental costs.

In each case, the racks transform disorganized storage into a streamlined part of the production process.

Why Choose Herochu: Certified Quality & Expert Support

When you invest in Herochu’s Heavy Duty Forklift Sheet Metal Storage Racks, you’re not just buying a product—you’re partnering with a team that understands industrial storage:

- Certified Reliability: CE, EU, and ISO 9001 certifications mean the racks meet global safety and quality standards, so you can trust their performance.

- Workshop-Focused Design: We design for your specific forklift model, sheet sizes, and layout, minimizing installation time and disruption.

- Transparent Value: Starting at $3,660, the racks deliver ROI through reduced labor costs, fewer material damages, and higher efficiency.

- Post-Sale Support: Our team provides installation guidance and maintenance tips to ensure your racks perform at their best for years.

Ready to Upgrade Your Heavy Sheet Storage?

Traditional pallets and basic racks are holding your facility back. Herochu’s Heavy Duty Forklift Sheet Metal Storage Racks let you work faster, safer, and more efficiently—all while protecting your valuable materials.

Contact Herochu today to discuss your workshop’s needs. Our industrial storage experts will create a customized solution, provide a detailed quote, and help you take the first step toward a more productive warehouse. With Herochu, heavy sheet metal storage isn’t a hassle—it’s a competitive advantage.

If you’d like to refine this further, feel free to share details like specific forklift models your target audience uses, unique industry pain points (e.g., outdoor storage needs), or additional add-ons to highlight. I can also adjust the focus to emphasize ROI metrics or customer success stories to boost engagement!