Revolutionizing Raw Material Storage: A Heavy-Duty Space Saving Roll Out Racks Success Story

In the competitive landscape of North American manufacturing, operational efficiency is not merely a goal—it is a fundamental requirement for survival and growth. Floor space is a premium asset, and its misuse represents one of the most significant, yet often overlooked, drains on profitability and safety. This was the precise challenge confronting a leading US-based manufacturer, whose struggle with sheet metal storage had become a critical bottleneck. Their experience, and the transformative solution provided by Herochu, stands as a powerful testament to the impact of intelligent warehouse design.

The Pre-Implementation Challenge: A Costly and Hazardous Status Quo

The manufacturer’s issue was a common one with severe consequences. Raw steel plates, essential to their production line, were stored using a traditional and overwhelmingly inefficient method: flat on the workshop floor. This approach consumed a vast expanse of valuable real estate that could otherwise be allocated to additional machinery, assembly lines, or future expansion. The disorganization was a constant source of friction. With materials of various types and similar thicknesses piled together, workers frequently faced the frustrating and costly problem of mixing up sheets. This led to incorrect cuts, wasted raw materials, project delays, and ultimately, a direct hit to the bottom line.

Beyond the financial implications, the safety hazards were alarming. The sharp, exposed edges of the scattered plates created a perpetual pedestrian hazard, significantly increasing the risk of lacerations or more severe injuries. This environment not only endangered employees but also contributed to material damage—scratches, deformation, and curled edges from improper handling were a regular occurrence, compromising the quality of the raw materials before they even entered production. The need for a systemic overhaul was undeniable.

The Herochu Solution: Implementing High-Capacity Steel Plate Storage Shelves

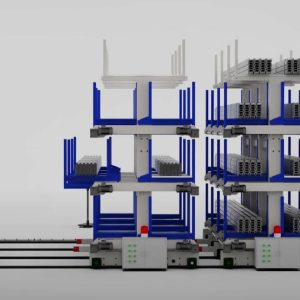

The search for a solution led them to Herochu and our engineered Heavy-Duty Space Saving Roll Out Racks. We engaged in a detailed consultation to understand the specific weight capacities, material sizes, and workflow requirements of their facility. The proposed solution was a state-of-the-art, customizable drawer-style racking system designed to conquer chaos with precision engineering.

A single, robust Herochu unit was configured to feature eight independently retractable drawer layers, complemented by a fixed top level. This intelligent design effectively created nine distinct, organized storage tiers within a remarkably compact vertical footprint. The transformation was immediate and profound. What was once a sprawling, dangerous patchwork of steel on the floor was now consolidated into a secure, vertical storage column, instantly reclaiming valuable square footage and dramatically enhancing the workshop’s safety profile.

Key Benefits and Measurable Operational Improvements

The adoption of the Herochu roll-out rack system yielded multifaceted benefits that extended across the entire operation:

- Unparalleled Space Optimization: The core advantage of these space saving roll out racks is their density. Because each drawer glides out independently along heavy-duty roller tracks, no industrial alleyways are required between units for forklift or crane access. This allows multiple units to be placed directly adjacent to one another, maximizing the use of every cubic foot of available vertical space and effectively tripling warehouse capacity without a single brick being laid.

- Dramatically Enhanced Efficiency & Productivity: Material retrieval was revolutionized. The integrated crane-operated access mechanism allows a single operator to handle loading and unloading tasks with unprecedented speed and safety. Instead of manually shifting through dangerous floor piles, workers can now effortlessly glide out a dedicated drawer, access the exact required plate with their overhead crane, and retract the drawer—all within minutes. This drastic reduction in handling time accelerates project timelines and optimizes labor allocation.

- Superior Safety and Material Integrity: Safety is the most critical improvement. The sharp edges of every sheet are now fully enclosed within the protective steel structure of the drawers, completely eliminating pedestrian trip and laceration hazards. Furthermore, storing plates flat and supported across their entire surface within the drawers prevents the scratches, warping, and edge damage synonymous with floor storage, ensuring material integrity and reducing waste.

- Streamlined Inventory Management: The systematic organization inherent to the Herochu system brought clarity to inventory management. With nine different material types or thicknesses stored in a dedicated, labeled location, visual checks and cycle counts became quicker and infinitely more accurate. This eliminated the errors of material misidentification, ensuring the right grade of steel is used for every job.

A Transformed Workshop Environment

Following the installation, the workshop was unrecognizable. The facility felt more organized, more spacious, and fundamentally safer. The palpable reduction in clutter reduced cognitive load for workers, allowing them to focus on precision tasks rather than navigating a hazardous storage yard. This systematic approach cultivated a culture of efficiency and order, resulting in a safer, more productive, and more profitable manufacturing environment.

Your Success Story Starts with Herochu

The challenges faced by this manufacturer are not unique. If your operation is constrained by inefficient storage, safety concerns, and material waste, your success story awaits. Herochu’s Heavy-Duty Space Saving Roll Out Racks are CE, EU, and ISO 9001 certified, guaranteeing the highest standards of quality, safety, and performance.

Customizable to your specific workshop layout and requirements, our systems start at an accessible $3,660. This is not an expense; it is a strategic investment in your company’s safety, efficiency, and future growth potential.

Contact Herochu today to schedule a consultation. Let our engineering team analyze your space and design a storage solution that will write your own operation’s next chapter of success.