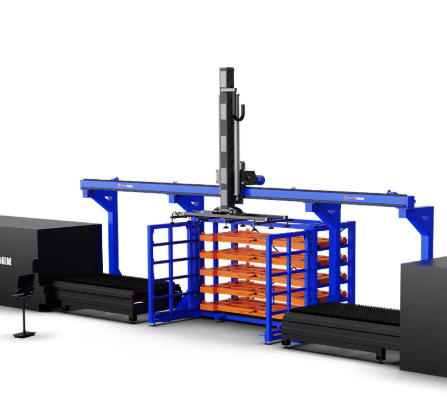

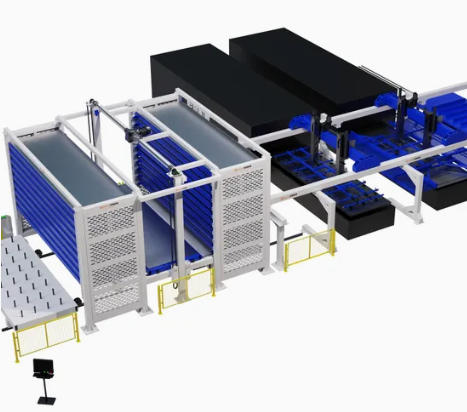

Herochu builds the answer in steel and chain, prices it from USD 8 900, and ships it with CE, EU and ISO 9001 paperwork already stamped. The towers stand 3 m to 25 m high, yet occupy the same footprint as two standard pallets. Inside that slice of floor, a chain-driven lifting carriage climbs at 9 m/min while an inlet shuttle travels at 12 m/min, delivering a 5 t pack of stainless steel to the laser table in under ninety seconds. One operator, one touch-screen, zero forklifts between rack and cutter.

Choose the size that matches your nest

Standard bay widths cover every popular sheet format: 3015, 4015, 4020, 6015, 6020, 6025 mm. Each tower houses 8–13 floors; load per floor is either 3 t or 5 t, so a single 6025 × 13 × 5 t module stores 325 t of material in 28 m². That is the equivalent of 18 block-stacked stillages vanished from the aisleways, freeing square metres for a second laser or a bending cell you never had room to install.

Linear guide rails + chain = speed without drama

A 50 × 50 mm hardened rail keeps the lifting carriage aligned to 0.2 mm over the full height. The chain is calibrated to 0.1 mm link tolerance, so repeatability remains inside ±0.5 mm even after 100 000 cycles. Vertical and horizontal drives share one 5.5 kW inverter; regenerative braking feeds descent energy back into the system, cutting average power demand to 0.9 kWh per cycle—less than a domestic kettle boiling for three minutes.

Pack support that respects surface quality

Laser-cut blanks destined for architectural cladding or white-goods outer skins cannot afford scratches. Herochu offers three support styles: rubber-coated fingers for general steel, nylon rollers for pre-painted sheet, and floating plastic skids for high-gloss stainless. Swap one for another in fifteen minutes; no tools, no re-calibration. The carriage also presents the pack at 900 mm above floor, the ergonomic sweet-spot for a single operator to peel off the top sheet without stooping.

Install today, expand next year

The frame bolts together like adult Meccano. Two technicians can erect a 6025 mm, 10-level tower during a weekend shutdown. If forecasts change, bolt-on sections add 1.5 m height increments, or a second tower can share the same aisle and transfer car. ERP integration is equally painless: an OPC-UA node is standard; SAP, Oracle, Microsoft Dynamics and most MES packages import the provided schema within hours. Should you change laser supplier, the handshake protocol adapts—no proprietary black box, no ransom upgrade fee.

Inventory you can see from the airport

Every tray carries an RFID tag. Scan a coil number on arrival and the system records alloy, thickness, weight, remnant percentage and heat certificate. When the planner releases a nest, the tower queues the correct pack, updates stock in real time and reserves the remnant for the next job. Out-of-stock alerts arrive by SMS; reorder reports export directly to the purchasing portal. One German fabricator reduced emergency material orders by 42 % in the first quarter after go-live.

Safety engineered for the Monday morning shift

Light curtains guard the aisle; break the beam and drives drop to safe-torque-off in 200 ms. Carriage overspeed is monitored by a mechanical governor that triggers a fail-safe brake rated at 150 % of maximum static load. Fork pocket sensors prevent a truck from entering while the shuttle moves; an acoustic beacon and flashing lamps warn when the tower is about to cycle. The control cabinet houses category-4 safety relays and a keyed lock-out for maintenance. These measures satisfy EN 15095, ISO 13849-1 and the forthcoming EU machinery regulation 2023/1230.

Data that pays for the steel

Cycle counters, energy meters and load-cell readouts stream to an on-board edge computer. Dashboards reveal peak demand hours, average dwell time per pack, and carriage mileage. One user noticed 30 % of retrievals happened between 07:45 and 08:15; by staggering shift start times they flattened the curve and delayed a planned second tower by eighteen months. Another site correlated remnant size with nest efficiency, cutting scrap rebates by USD 120 000 per year.

Labour redeployed, not redundant

Instead of two forklift drivers shuttling stillages, one technician oversees the tower HMI and prepares the next nest. Skilled welders move from dragging plate to programming parts—higher value work that justifies wage increases and improves retention during a labour shortage. Insurance underwriters notice: one UK client saw employers’ liability premium fall 8 % after documenting zero manual-handling incidents post-installation.

Cost trajectory that favours the bold

Purchase price opens at USD 8 900 for a 3015 mm, 8-floor, 3 t-per-shelf light module. A flagship 6025 mm, 13-floor, 5 t heavy tower with twin transfer cars and ERP node closes near USD 49 000. Energy, maintenance and software subscriptions add roughly USD 1.40 per tonne moved. Compare that to forklift amortisation, fuel, pallet wear, aisle occupancy and the hidden cost of lost remnants, and payback lands between ten and fourteen months in typical European job-shops.

Delivery and commissioning you can set your watch to

Steel sections are shot-blasted, zinc-primed and finished in RAL 5017 traffic blue. Chain and motors are pre-wired into the mast; on-site work is limited to bolting frames, levelling rails and connecting mains. A three-person Herochu crew completes mechanical assembly in one shift, electrical commissioning the next morning, and operator training by lunch. A signed acceptance certificate triggers the warranty: five years on structure, two years on drives, lifetime on control software updates.

The tower that starts as storage ends as strategy

Automatic warehouses for sheet metal storage revolutionize efficiency by compressing inventory into vertical space, feeding machines at robotic speed, and turning stock data into scheduling power. Herochu simply delivers that revolution at a price smaller shops can justify and larger plants can scale without limit. Request the dimension sheet, slot the tower into your next budget round, and spend the following quarter watching forklift traffic disappear while laser uptime climbs toward the theoretical maximum you paid for but never reached—until now.