How to Choose the Right Sheet Metal Storage System: Prioritize ROI, Efficiency, and Durability

For manufacturing, construction, and metalworking businesses, choosing the right sheet metal storage system isn’t just about finding a place to hold inventory—it’s about solving core operational challenges: wasted space, high labor costs, material damage, and inflexibility. The wrong system can drain budgets, slow production, and erode profits, while the right one becomes a driver of efficiency and long-term savings. Herochu’s sheet metal storage systems—customizable to your workshop, starting at $3,660 and certified to CE, EU, and ISO 9001 standards—are designed to address these pain points. This guide breaks down how to select a system that balances immediate needs with long-term ROI, ensuring your investment delivers tangible value.

Start by Mapping Your Pain Points: What Are You Trying to Fix?

The first step in choosing the right sheet metal storage system is to identify your biggest warehouse struggles. Most businesses face one or more of these common issues:

- Wasted space: Limited warehouse square footage means you can’t afford to let vertical or horizontal space go unused. Traditional vertical stacking or fixed racks often leave gaps, forcing you to rent extra space or turn down orders due to storage constraints.

- High labor costs: Manual handling of sheet metal—especially heavy steel or aluminum—requires multiple workers, slow retrieval times, and increases the risk of injury. This eats into payroll budgets and drags down productivity.

- Material damage: Sheet metal is prone to scratching, warping, or edge dents when stacked or moved improperly. Damaged stock means reordering costs, production delays, and wasted resources.

- Inflexibility: Market demands shift—one month you’re storing 4x8ft aluminum sheets, the next 10ft steel plates. A rigid storage system can’t adapt, leaving you with unused capacity or overcrowded racks.

Herochu’s sheet metal storage systems are built to solve all these. By focusing on space efficiency, labor savings, material protection, and flexibility, they turn storage from a cost center into a competitive advantage.

Evaluate Space Efficiency: Maximize Storage Density to Cut Rental Costs

Space is one of your warehouse’s most valuable assets—so your storage system should make every square foot count. When comparing options, ask: Can this system increase storage density without making materials hard to access?

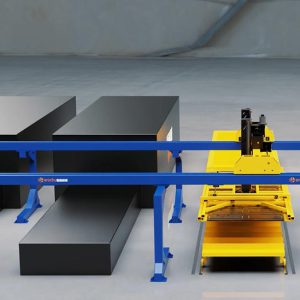

Herochu’s horizontal sheet metal storage systems excel here. Unlike traditional racks that force you to work around fixed dimensions, our designs are adjustable to fit your inventory. You can customize the number of layers (from 2 to 10, with custom upgrades available) and layer spacing (50mm to 200mm) to match sheet sizes—thin aluminum on one layer, thick steel on another—no wasted vertical space. The horizontal layout also eliminates the gaps common in vertical stacking, boosting overall space utilization by 25-30%.

Prioritize Labor Savings: Simplify Retrieval to Reduce Headcount Costs

Labor is another major expense for warehouses—and sheet metal storage can be a labor drain if the system is cumbersome. Traditional methods often require two or three workers to move, stack, and retrieve sheets, plus extra time spent digging through piles to find the right one. The right storage system should let a single worker handle tasks quickly and safely.

Herochu’s systems feature 100% extractable drawers with smooth-rolling wheels. A single operator can slide a drawer out, grab the exact sheet they need, and close it—no lifting, no shifting other materials, no waiting for a team. This cuts retrieval time by 30-40% and eliminates the need for multi-person crews.

A building materials supplier in Ohio saw immediate results: “Before Herochu, two people spent 3 hours a day retrieving sheet metal. Now one person does it in 90 minutes. Labor costs dropped by 20%, and our team has time to focus on other tasks.” When choosing a system, look for ergonomic, user-friendly designs—efficiency here directly translates to lower payroll bills.

Protect Your Inventory: Minimize Damage to Avoid Rework and Replacement Costs

Sheet metal is expensive—so a storage system that damages your stock is costing you money. Traditional stacking crushes edges, scratches surfaces, and warps thin sheets, leading to rework, replacements, and missed deadlines. The right system should act as a protector, not just a holder.

Herochu’s horizontal design keeps sheets flat and separated, reducing friction and pressure between layers. The powder-coated steel surfaces resist scratches, and the stable layout prevents warping—even for delicate materials like stainless steel or pre-painted aluminum.

When evaluating systems, check for features that protect your inventory: smooth surfaces, secure drawer latches, and stable weight distribution. Damage reduction isn’t just a “nice-to-have”—it’s a direct line to lower operational costs.

Demand Flexibility: Choose a System That Grows With Your Business

Market demands change—your storage system should too. A rigid system that only fits one sheet size or weight will become obsolete as your business expands or shifts focus. Look for modular, scalable designs that adapt to new needs.

Herochu’s sheet metal storage systems are fully modular. You can add layers, adjust spacing, or even relocate sections if you move warehouses. Need to switch from storing 4ft sheets to 10ft sheets? Simply reconfigure the drawer lengths—no tools, no downtime. This flexibility means your initial investment keeps working for you, even as your inventory changes.

A metalworking shop in Michigan expanded its product line to include custom steel plates and was able to reconfigure their Herochu system in a day: “We didn’t have to buy new racks—we just adjusted the layers. That saved us $15,000 in new equipment costs.”

Verify Certifications and Cost: Ensure Quality and Long-Term Value

Finally, don’t overlook quality and compliance. A cheap, uncertified system may save money upfront but will cost more in repairs, replacements, and downtime. Herochu’s systems are CE, EU, and ISO 9001 certified—meaning they meet strict international standards for safety, durability, and performance. You’re not just buying a rack; you’re buying a system that will last for years.

Choose Herochu: A System Built for Your Success

When you’re asking “How to Choose the Right Sheet Metal Storage System,” the answer comes down to one question: Does this system solve my pain points and deliver ROI? Herochu’s customizable, certified, and efficient systems do both. Whether you’re a small fabrication shop or a large construction firm, we’ll tailor the system to your workshop’s layout, inventory, and budget.

Contact Herochu today to discuss your storage needs and get a personalized quote. With our sheet metal storage systems, you’re not just storing materials—you’re building a more efficient, cost-effective, and profitable business.