Improving Efficiency in a Sheet Metal Storage Warehouse: A Case Study of Herochu’s Storage Solutions

For sheet metal manufacturers, a disorganized storage warehouse isn’t just a messy space—it’s a drain on productivity, a risk to safety, and a source of unnecessary costs. When a leading US-based manufacturer found itself drowning in unorganized raw steel plates, with wasted space, material mix-ups, and safety hazards plaguing its operations, it turned to Herochu’s customizable sheet metal storage systems. The result? A transformed warehouse, boosted efficiency, and tangible cost savings—proving why Herochu’s solutions, starting at $3,660 and certified to CE, EU, and ISO 9001 standards, are the answer to improving efficiency in sheet metal storage.

The Crisis: How Disorganized Storage Broke Down Operations

Before partnering with Herochu, the US manufacturer faced a perfect storm of storage-related issues that threatened its bottom line. Raw steel plates of varying types, sizes, and thicknesses were haphazardly laid flat across the workshop floor—a method that consumed nearly 40% of its available space, leaving little room for equipment movement or additional inventory. This lack of organization led to frequent mix-ups: plates with similar thicknesses were mistaken for one another, resulting in incorrect laser cuts and wasted material. Over six months, these errors cost the company over $15,000 in scrapped steel and rework.

Worse, the exposed plates posed severe safety risks. Sharp edges jutted out from piles, increasing the likelihood of lacerations for employees navigating the floor. In the year prior to the upgrade, the facility reported three minor injuries related to material handling—incidents that disrupted workflow, raised workers’ compensation costs, and lowered team morale. “We were spending more time fixing mistakes and navigating hazards than actually producing,” said the manufacturer’s operations manager. “Our storage system was holding us back.”

The Herochu Solution: Drawer-Style Racking That Reclaims Space & Safety

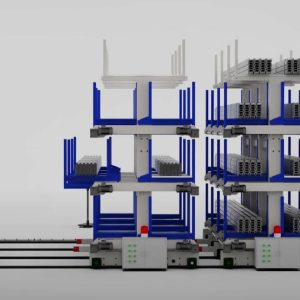

To address these challenges, Herochu recommended its high-capacity drawer-style steel plate storage shelves—a customizable system engineered to turn chaotic storage into streamlined efficiency. The core of the solution was a modular racking unit featuring eight retractable drawer layers and a fixed top shelf, all designed to maximize vertical space while keeping materials accessible.

Unlike the manufacturer’s previous floor-stacking method, Herochu’s system organizes up to nine different sheet metal types in a single compact footprint. Each drawer extends fully, allowing workers to access stored plates without moving adjacent materials, and the fixed top shelf provides additional space for bulk or less-frequently used stock. The system was tailored to the manufacturer’s specific needs: drawer dimensions were adjusted to fit their most common sheet sizes (from 4×8 ft. steel plates to smaller alloy sheets), and load ratings were calibrated to support their heaviest materials (up to 500kg per drawer).

Installation was seamless, too. Herochu’s team worked around the manufacturer’s production schedule, setting up the racks during off-hours to avoid downtime. Within two days, the first set of shelves was operational—immediately beginning to resolve the company’s storage woes.

The Transformation: Efficiency, Safety, and Savings Unlocked

The impact of Herochu’s storage system was immediate and measurable, with improvements felt across every aspect of the manufacturer’s operations.

1. Space Reclaimed, Capacity Tripled

By shifting from floor-stacking to vertical, drawer-style storage, the manufacturer reclaimed 35% of its workshop floor space—enough to add a new laser cutting machine without expanding the facility. A single Herochu rack replaced 120 square feet of floor-stacked plates, and the dense arrangement (no industrial alleys needed between units) maximized vertical height, pushing storage capacity from 200 plates to 600 in the same area. “We went from struggling to fit our current inventory to having room to grow,” the operations manager noted.

2. Retrieval Time Cut by 70%

The retractable drawers and crane-compatible design eliminated the need for manual lifting or forklift maneuvering to access buried plates. Previously, retrieving a specific sheet could take 15–20 minutes; with Herochu’s system, it takes just 3–5 minutes. A single operator can now handle loading and unloading, freeing up two additional team members to focus on production tasks. Over a month, this translated to 120+ hours of saved labor—equivalent to three full workweeks.

3. Material Waste Reduced to Near Zero

Categorized storage eliminated mix-ups between similar-looking plates. Each drawer is labeled by material type, thickness, and grade, so workers grab the correct sheet on the first try. In the six months after installation, the manufacturer’s material scrap rate dropped from 8% to less than 1%, saving over $14,000 in raw material costs alone. The shelves also protect plates from damage: enclosed drawers prevent scratches, deformation, and curled edges, ensuring every sheet is usable when retrieved.

4. Safety Risks Eliminated

With sharp-edged plates securely stored in drawers, the workshop’s injury risk plummeted. In the year following installation, the facility reported zero material-handling injuries. “Employees no longer have to navigate around piles of steel,” the safety manager said. “The drawers keep everything contained, and the clear labeling means no one is reaching blindly for materials.” This improved safety also boosted team confidence and productivity, as workers could focus on tasks without worrying about hazards.

5. Inventory Management Simplified

Organized storage turned inventory counts from a day-long chore into a 30-minute task. Each drawer’s label corresponds to the manufacturer’s inventory management software, and cycle counts are as simple as checking the drawer’s contents. Stockouts of high-demand plates became a thing of the past, as the team could quickly identify low inventory and reorder in time. “We used to overstock to avoid running out,” the operations manager explained. “Now we order exactly what we need, cutting our inventory holding costs by 20%.”

Why Herochu’s Storage Solutions Deliver Results

This case study isn’t an anomaly—it’s a testament to how Herochu’s systems are built to solve real-world sheet metal storage challenges. What sets Herochu apart?

- Customization: Every system is tailored to your workshop’s size, material types, and workflow—no one-size-fits-all solutions.

- Space Efficiency: Vertical, dense designs maximize storage capacity without expanding your footprint.

- Safety & Durability: CE, EU, and ISO 9001 certifications ensure compliance with global safety standards, and industrial-grade construction guarantees long-term performance.

- Accessible Investment: Starting at $3,660, Herochu’s systems deliver ROI in months, not years—like the US manufacturer, which recouped its cost in just five months.

Your Turn: Improve Efficiency in Your Sheet Metal Storage Warehouse

If your workshop is struggling with wasted space, material mix-ups, safety hazards, or inefficient retrieval—you’re not alone. The US manufacturer’s story proves that the right storage system can transform your operations. Herochu’s customizable drawer-style racking, fixed shelves, and hybrid solutions are designed to address your unique pain points, whether you’re a small fabricator or a large-scale manufacturer.

This case study is just one example of how Herochu helps businesses improve efficiency in sheet metal storage. Your workshop could be next.

Ready to reclaim space, cut costs, boost safety, and streamline operations? Contact Herochu today to schedule a free storage assessment and design a custom solution for your warehouse.