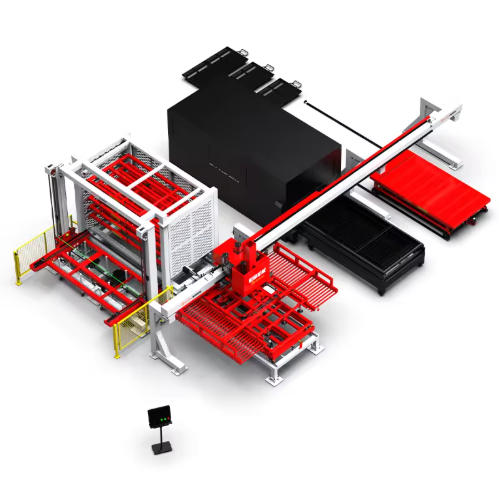

Herochu Laser Cutter Loading System: The Smart Choice for Modern Fabrication Shops

Why Manual Loading is Killing Your Productivity

In today’s fast-paced manufacturing environment, manual sheet handling can waste up to 40% of your laser cutter’s productive time. Herochu’s CE/UE/ISO 9001-certified automatic loading system eliminates this inefficiency with:

- 12m/min loading speed (3x faster than manual methods)

- 3-5 ton per layer capacity for heavy-duty materials

- 8-13 floor storage for batch processing

Starting at just $8,900, our systems pay for themselves in under 12 months through reduced labor costs and increased machine utilization.

How It Works: Precision Engineering for Laser Cutting

1. High-Speed Material Handling

- Linear guide rail + chain drive for smooth, vibration-free operation

- 9m/min vertical lifting with 12m/min horizontal transfer

- Universal compatibility (3015mm to 6025mm work areas)

2. Smart Automation Features

- Dual-table synchronization for continuous operation

- Vacuum lifting options for delicate materials

- Real-time monitoring via integrated PLC system

3. Industry-Specific Customization

| Industry | Key Benefits |

|---|---|

| Automotive | High-volume part sorting with 99.9% accuracy |

| Aerospace | Titanium handling with ±0.1mm precision |

| Architectural | Large-format sheet processing (up to 6m) |

Technical Specifications

| Parameter | Specification |

|---|---|

| Max Sheet Size | 6m × 3m |

| Thickness Range | 0.5–30mm |

| Power Supply | 380V/50Hz, 30KVA |

| Cycle Time | 110 seconds (full automation) |

Get a Custom Quote Today

To optimize your system, specify:

- Material types (e.g., 10mm stainless steel)

- Daily output requirements

- Existing machine models

Herochu engineers will design a solution that fits your production floor.