Herochu Laser Cutting: Automation of Loading and Unloading – Fiber Laser Cutter Efficiency Boost

For shops relying on manual material handling for fiber laser cutting, every pause to load sheets, adjust pallets, or fix misalignments eats into productivity. Herochu’s Laser Cutting: Automation of Loading and Unloading changes that. This cutting-edge system isn’t just an add-on—it’s a fully integrated solution that turns standalone laser cutters into 24/7 production powerhouses. Starting at $35,000, fully customizable, and backed by CE, UE, and ISO 9001 certifications, it slashes labor costs, eliminates material waste, and keeps your workflow running nonstop—even in high-speed, high-volume environments.

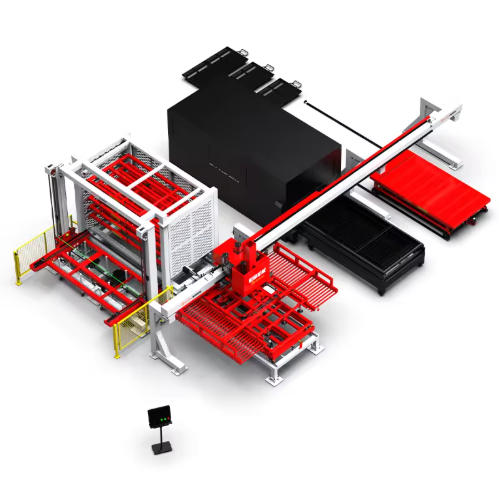

More Than Just Loading: A Fully Automated Laser Cutting Ecosystem

Herochu’s system is designed for fiber laser cutters, but it goes far beyond basic loading and unloading. It combines three critical functions—material handling, storage, and cutting integration—into one seamless setup. Need to store stacks of metal sheets? The multi-level warehousing system (customizable to your workshop’s space) holds up to 24MT total—enough to keep large-scale production going without constant material restocks. Want to skip manual oversight? The system links directly to your CNC machines, creating a fully automated line where sheets move from storage to cutter to finished pallet with zero human intervention.

This isn’t just about convenience—it’s about consistency. Manual handling leads to misaligned sheets, wasted material, and uneven cutting. Herochu’s automation eliminates those variables: every sheet is lifted, positioned, and unloaded with precision, ensuring every cut matches your specs. And with a large protective housing around the cutter, you get two bonuses: radiation safety for your team and protection against mechanical damage to the machine—extending its lifespan.

Technical Specs That Deliver High-Speed, Heavy-Duty Performance

What makes this system stand out in busy workshops? It’s built for speed, strength, and reliability—with specs that solve real-world production challenges:

Speed That Cuts Wait Time

When every second counts, slow loading kills efficiency. Herochu’s system moves at a lifting speed of 0.25m/s and a translational speed of 0.4m/s—fast enough to keep up with even the fastest fiber laser cutters. And the continuous feeding time? As short as 110 seconds. That means after one sheet is cut, the next is in place almost instantly—no more waiting for a worker to haul material over. For example, when cutting 10mm stainless steel, this system boosts speed by at least 10% compared to ordinary manual setups. You get double the output without sacrificing cut quality.

Strength to Handle Large Loads

24MT total storage capacity isn’t just a number—it’s a game-changer for large-scale shops. Whether you’re working with thin aluminum sheets or thick steel plates, the system handles heavy loads effortlessly. No more limiting production because you can’t store enough material. The heavy-duty frame and storage racks are engineered to support those 24MT loads without bending or wear, even with daily use.

Precision That Reduces Waste

Mechanical vibration is the enemy of laser cutting precision. Herochu’s system has a vibration value of ≤0.5G—so the machine stays stable during every move. Less vibration means less mechanical wear (extending part life) and more consistent cuts (reducing scrapped material). Plus, the system uses real-time height detection for finished materials: as soon as a pallet is full, it sends an intelligent alert. No more overloading pallets or leaving finished parts sitting idle—keeping your workflow smooth.

Adaptability to Your Workshop

Industrial environments aren’t one-size-fits-all, and neither is this system. It operates in temperatures from -10°C to 45°C—so whether your workshop is in a cold warehouse or a warm manufacturing bay, it performs reliably. It runs on a 30KVA power supply, optimized for energy efficiency—so you get high performance without sky-high utility bills. And if you need to adjust for different sheet sizes or cutting needs? The entire system is customizable: add more storage levels, tweak feeding speeds, or integrate with additional laser cutters.

Why This System Slashes Costs (and Boosts Profits)

Automation isn’t just about speed—it’s about smart spending. Herochu’s Laser Cutting Automation delivers three key cost-saving benefits:

Labor Costs Cut in Half

With batch automatic cutting and zero manual intervention, you don’t need a team member dedicated to loading sheets. Your staff can focus on higher-value tasks—like quality control or machine maintenance—while the system handles the repetitive work. Over time, this adds up to major labor savings, especially for 24/7 operations.

Material Waste Reduced to “0” Tailings

The system’s precise motion control and smart material management mean you use every inch of your metal sheets. No more leftover scraps from misaligned loading or inefficient cutting. The humanized design optimizes raw material usage, turning “waste” into finished parts—and boosting your bottom line.

Low Operating Costs

Forget expensive nitrogen cutting. Under the same power, Herochu’s system has a cutting cost that’s only 10% of nitrogen cutting. That’s a massive savings for shops that cut large volumes of metal. And with minimal mechanical wear (thanks to low vibration) and a protective housing that prevents damage, you’ll spend less on repairs and replacements, too.

Industries That Benefit Most

This system isn’t limited to one sector—it’s built to solve material-handling problems across industries that rely on laser cutting:

- Engineering Machinery: Cut thick steel plates for heavy equipment without manual lifting.

- Electrical Cabinet & Elevator Industries: Batch-produce precise metal components for cabinets or elevator parts.

- Kitchen Equipment & Lighting Hardware: Handle thin to medium metal sheets for appliances or fixtures with speed.

- Auto Parts & Exhibition Equipment: Meet high-volume demands for custom-cut parts with zero downtime.

- Sheet Metal Processing: Turn small-batch jobs into high-volume production with fully automated workflows.

Whether you’re cutting stainless steel, aluminum, or other metals (in varying thicknesses), the system works efficiently and stably—even during long shifts.

Why Choose Herochu’s Laser Cutting Automation?

Certifications matter when it comes to industrial equipment—and Herochu’s system is CE, UE, and ISO 9001 certified, so you know it meets global standards for safety, quality, and performance. But beyond certifications, here’s what sets us apart:

- Customization: We don’t make you fit our system—we design the system to fit your workshop. Need more storage? A faster feeding speed? Integration with multiple lasers? We’ll build it.

- Reliability: With low vibration, a protective housing, and energy-efficient design, this system is built to run for years with minimal maintenance.

- Support: From installation to training, our team helps you get the most out of your automation. We’ll show your staff how to use the system, troubleshoot issues, and adjust settings for new jobs.

Ready to Turn Your Laser Cutter Into a Production Powerhouse?

If manual loading is slowing you down, material waste is eating into profits, or labor costs are too high, Herochu’s Laser Cutting: Automation of Loading and Unloading is the solution. Starting at $35,000, it’s an investment that pays for itself—with faster output, lower costs, and a workflow that runs without interruption.

Contact us today to discuss your needs: tell us your laser cutter type, the metal sheets you work with, and your production volume. We’ll customize a system that fits your shop and give you a quote. With Herochu, laser cutting automation isn’t just for big factories—it’s for any shop that wants to work smarter, not harder.