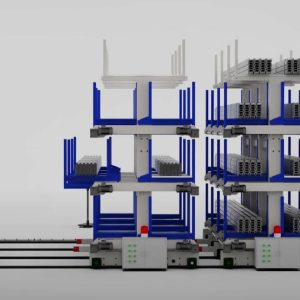

Herochu Heavy Duty Cantilever Racking Systems: Built for Safety, Designed for Longevity

The Next Phase of Your Storage Investment

When your CE, EU, and ISO 9001-certified Herochu cantilever racking system is installed, it marks the beginning of a decades-long partnership—not just a one-time purchase. These racks are engineered to withstand the rigors of industrial environments, but their true value is unlocked through proper use, routine maintenance, and a culture of safety awareness.

This guide is not about complex engineering manuals. It’s about practical, actionable best practices that protect your team, your materials, and your investment.

The Golden Rules of Safe Loading

1. Always Know Your Capacity

- Every arm and column is labeled with its maximum load rating. Never exceed it.

- Capacity is based on evenly distributed loads. Concentrated weight reduces safe limits.

2. Load from the Bottom Up

- Fill lower levels first to maintain the rack’s center of gravity.

- Avoid creating top-heavy configurations that compromise stability.

3. Distribute Weight Evenly

- Place 20-foot bundles so they span multiple arms, not just the ends.

- Ensure weight is spread across all arms in a bay, not concentrated on one.

4. Place, Don’t Push

- Gently lower materials onto arms. Never force a bundle into the rack—lateral stress damages columns.

5. No Climbing

- The rack is not a ladder or access platform. Climbing risks structural failure and falls.

Monthly Visual Inspection Checklist

Designate a team member to perform this 15-minute check monthly:

| Component | What to Check |

|---|---|

| Columns | Look for forklift impacts (dents, bends). Ensure they remain perfectly plumb. |

| Arms | Check for deflection or bending. Verify locking pins/bolts are secure. |

| Bracing | Inspect horizontal/diagonal braces for straightness and tight connections. |

| Anchors | Confirm base bolts are tight with no gaps. |

| Load Labels | Ensure labels are legible and accurate. |

If damage is found:

- Immediately unload the affected area.

- Report for professional assessment before reuse.

Building a Culture of Safety

1. Report All Impacts (No-Fault Policy)

- Encourage operators to report collisions immediately.

- Hidden damage leads to catastrophic failures.

2. Keep Aisles Clear

- Aisles are not storage zones. Blocked aisles increase accident risks.

3. Install Column Protectors

- Floor-mounted guardrails or bumper guards prevent forklift damage.

- A small cost to avoid costly repairs.

From Investment to Perpetual Asset

By adopting these practices, your Herochu cantilever racking system transitions from a purchase to a long-term asset. You’ll achieve:

✅ Extended lifespan (decades of reliable use).

✅ Reduced downtime (proactive maintenance prevents failures).

✅ Enhanced safety (protecting personnel and materials).

Contact Herochu today for a free safety audit or customized training for your team.