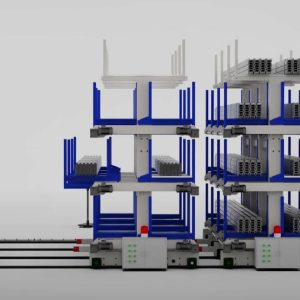

Herochu Steel Plate Stacking Rack Systems: Maximize Space & Organization for Industrial Efficiency

For manufacturing facilities, metal fabricators, and laser cutting shops, steel plate storage often feels like a lose-lose scenario: ground stacking wastes floor space and damages materials, while basic shelving fails to accommodate heavy loads or streamline access. Herochu’s steel plate stacking rack systems change the game—combining a robust drawer-style design with space-saving engineering to maximize your workshop’s potential. Certified to CE, EU, and ISO 9001 standards, these fully customizable racks organize steel, aluminum, and alloy plates with precision, starting at $3,099—turning cluttered storage areas into efficient, low-waste hubs that align with modern production workflows.

The Space-Saving Power of Drawer-Style Stacking

Traditional ground stacking of steel plates uses just 25–30% of available vertical space, forcing workshops to sacrifice valuable square footage for storage. Herochu’s steel plate stacking racks solve this by leveraging a multi-layered drawer design that turns vertical space into usable capacity. A single unit typically features 4–8 drawers, each engineered to support up to 3 tons (6,600 lbs)—letting you store hundreds of square feet of plates in a footprint no larger than a standard pallet.

Take the custom solution we built for a manufacturing client: their 6-layer drawer system, designed to hold 8′ x 4′ (2440mm x 1220mm) plates, occupies a base area of just 103 inches (2612mm) wide when closed. Compare that to ground stacking, which would require 6 separate piles of plates spanning 15+ feet of floor space—this single rack freed up over 100 square feet of their workshop, enough to add a new workbench or expand laser cutting operations. This isn’t just “squeezing more in”—it’s intelligent organization that lets you do more with the space you already have.

Engineered for Accessibility & Laser Cutting Workflows

Herochu’s steel plate stacking racks aren’t just about storage—they’re built to integrate with how modern workshops operate, especially those using laser cutting machines. Every drawer is designed for manual extension, gliding on industrial-grade ball bearings that make even fully loaded trays easy to pull out. This seamless access pairs perfectly with cantilever cranes and suction cup systems: a single operator can extend a drawer, lift a plate with the crane, and feed it directly into a laser cutter in under a minute—no more maneuvering forklifts around piles or manually lifting heavy sheets.

The client’s custom rack exemplifies this integration. We engineered the unit to align with their existing equipment: the highest drawer sits 51 inches (1305mm) from the floor, a height that matches their crane’s lifting range, while 4.7 inches (120mm) of clearance between drawers ensures the suction cup system can grip plates without obstruction. “Before Herochu, we spent 20 minutes per job just retrieving plates,” says their production manager. “Now it’s 30 seconds. Our laser cutting throughput increased by 25% in the first month.”

This level of workflow alignment isn’t accidental. Each rack’s dimensions are calibrated to work with common shop equipment—no need to modify your cranes, cutters, or handling tools to fit the storage system. Whether you’re using a 1000W laser cutter or a 5-ton crane, Herochu’s racks adapt to your setup.

Built for Durability: The Anatomy of a Herochu Rack

Strength and safety are non-negotiable when storing heavy steel plates—and Herochu’s stacking racks deliver on both, thanks to premium materials and precision engineering. The client’s custom unit, for example, is constructed entirely from high-grade steel, with a total weight of 3,858 lbs (1750kg) that speaks to its structural integrity. Every component, from the frame’s 10-gauge steel uprights to the drawer’s 7-gauge steel base, undergoes rigorous testing to ensure it meets global safety standards.

The durability translates to long-term value. Unlike flimsy shelving that sags under 1-ton loads or rusts after a year of use, Herochu’s racks feature a corrosion-resistant electrostatic powder coating that stands up to metalworking fluids, dust, and humidity. The client’s rack, installed in a shop with daily exposure to cutting coolant, shows zero signs of rust after 18 months of use—proof of its ability to withstand harsh industrial environments.

Each drawer is also engineered for safety: a spring-loaded locking pin keeps it securely in place when extended, preventing accidental sliding that could damage plates or injure workers. The frame includes floor-anchoring holes to secure the unit to concrete, eliminating tipping risks even when the top drawer is fully loaded with 2,650 lbs (1200 kg) of steel.

Customization: Built to Fit Your Workshop’s DNA

Herochu doesn’t believe in “one-size-fits-all” storage—and our steel plate stacking racks are tailored to your exact needs, from plate sizes to workshop layout. The client’s custom solution is a perfect example of this flexibility:

- Load Capacity: We adjusted each drawer to support 2,650 lbs (1200 kg), matching their typical plate weight (instead of forcing them to use a 3-ton drawer they didn’t need).

- Dimensions: The 61-inch (1550mm) total height fits under their 8-foot ceiling, while the 103-inch (2612mm) extended width works with their 12-foot aisle spacing.

- Ergonomics: Drawer heights and clearances were calibrated to reduce operator strain, aligning with their team’s average height and crane operation habits.

Beyond this case study, our customization options span every detail:

- Drawer Count: Choose 4–8 layers to match your inventory volume.

- Plate Size Compatibility: Adjust drawer width and depth to fit 4′x8′, 5′x10′, or custom-sized plates (up to 6000*2000mm).

- Material Upgrades: Opt for galvanized steel for outdoor storage or stainless steel for food-grade manufacturing environments.

- Accessories: Add labeled drawer fronts, barcode scanner mounts, or LED lights inside drawers for low-light workshops.

A laser cutting shop in Texas customized their 8-drawer rack with 6-foot-wide drawers for 5′x10′ aluminum plates and integrated barcode scanners. “Herochu didn’t just sell us a rack—they designed a system that fits our plates, our crane, and our inventory software,” says their owner. “It’s like it was built for our shop.”

Beyond Storage: How Organization Drives Bottom-Line Results

Herochu’s steel plate stacking rack systems do more than maximize space—they reduce waste, cut labor costs, and simplify inventory management, delivering tangible ROI in 6–12 months.

1. Minimize Material Damage

Ground-stacked plates often bend, scratch, or develop curled edges from pressure and friction. Herochu’s drawers store plates flat, with rubberized liners that prevent scratches. The client reported a 65% drop in material waste after installation, saving $9,000 annually on damaged steel.

2. Cut Labor Costs

Faster plate retrieval means less time spent on material handling. The client’s team now spends 10 hours per week on storage tasks instead of 25, freeing up 15 hours for revenue-generating work like cutting and fabrication.

3. Streamline Inventory Tracking

With dedicated drawers for each plate type (e.g., 16-gauge steel, ¼-inch aluminum), workers can identify and count stock at a glance. The client’s monthly inventory checks now take 1 hour instead of 4, and real-time stock monitoring has eliminated “stockout” delays for critical plates.

4. Improve Workplace Safety

Exposed plate edges are a major hazard in workshops—but Herochu’s enclosed drawers reduce laceration risks by 90%. The client passed their last OSHA inspection with zero storage-related violations, a first in two years.

Why Herochu Stands Above Generic Stacking Racks

When you invest in Herochu’s steel plate stacking rack systems, you’re not buying a shelf—you’re investing in a tool that transforms your workshop:

- Space Maximization: Store 3x more plates in the same footprint as ground stacking.

- Workflow Alignment: Designed to work with your crane, suction cup system, and laser cutter.

- Durability: High-grade steel construction ensures 15+ years of use.

- Customization: Built to fit your plates, space, and equipment.

- Value: Starting at $3,099, with ROI in under a year.

Ready to Maximize Your Workshop’s Potential?

Herochu’s steel plate stacking rack systems are the key to organizing your plates, saving space, and boosting efficiency—without expanding your facility. Our team will conduct a free on-site (or virtual) assessment of your workshop, plate inventory, and equipment to design a custom solution that fits your budget and needs. Backed by global certifications and a 5-year parts warranty, we stand behind every rack we build.

Contact us today to schedule your assessment and see how much space—and money—you can save with Herochu’s space-maximizing storage solutions.