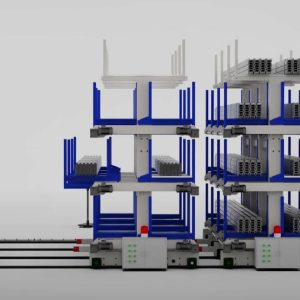

Herochu New Heavy Duty Structural Cantilever Rack: Engineered for Safety, Built with Transparency

When you’re investing in new heavy duty structural cantilever rack, you’re not just buying steel—you’re buying a critical piece of your facility’s safety infrastructure. Industrial buyers know the difference between a generic rack and an engineered system: the former cuts corners to hit a low price, while the latter is built to withstand decades of heavy loads, harsh environments, and daily use. Herochu’s new heavy duty structural cantilever rack is designed for the intelligent buyer—one who asks the hard questions about engineering, materials, and support. Fully certified to CE, EU, and ISO 9001 standards, our racks don’t just meet expectations; they answer the 5 critical queries that separate reliable suppliers from risky ones.

For manufacturers, construction firms, and warehouse managers storing long, heavy materials—from 10-ton steel beams to 6-meter aluminum profiles—settling for a “good enough” rack isn’t an option. Catastrophic failures, workplace injuries, and unplanned replacements cost far more than investing in quality upfront. Herochu’s structural cantilever rack is built to eliminate that risk, with transparent engineering, premium materials, and a partnership approach that extends long after delivery. This is how we answer the questions that matter most to the buyers who know better.

1. “Can You Provide Stamped Engineering Calculations for My Load?”

The first rule of a safe structural cantilever rack is: no guesswork. Herochu doesn’t just “build strong racks”—we engineer systems tailored to your exact load requirements. Every order comes with a licensed engineer-stamped report detailing arm capacity, column strength, base stability, and wind load resistance (critical for outdoor storage). For example, if you’re storing 8-ton steel plates on 2.5m arms, our report will show how we calculated the arm deflection (limited to 1/150 of arm length, per ISO 9001 standards), the column’s ability to resist lateral stress, and the total system’s stability under dynamic loads (like forklift placement).

We never say, “It’s strong enough.” Instead, we show you. This documentation isn’t just for compliance—it’s your guarantee that your rack is built to handle your materials, not a generic “heavy load.” For facilities undergoing OSHA or EU safety audits, these stamped calculations are tangible proof of due diligence.

2. “What Specific Grade of Steel Do You Use?”

A rack is only as strong as its raw material—and Herochu doesn’t hide behind vague claims like “high-quality steel.” Our new heavy duty structural cantilever racks are constructed from Q355B low-alloy high-strength steel (equivalent to S355JR in EU standards) for columns and arms, with Q235B steel for reinforcing braces. Why Q355B? It offers 20% higher tensile strength than standard Q235 steel, meaning thinner components can handle the same load—or thicker components can support heavier weights, reducing overall rack footprint.

We source our steel directly from ISO 9001-certified mills in Shandong, China, and provide mill test certificates (MTCs) with every order. This transparency lets you verify the steel’s chemical composition and mechanical properties, ensuring it meets CE and EU material standards. For buyers in corrosive environments (e.g., coastal warehouses or chemical facilities), we also offer optional galvanized steel components—still Q355B, but treated to resist rust for 20+ years.

3. “Can You Detail Your Welding and Powder Coating Process?”

Durability lives in the joints and the finish—and Herochu’s manufacturing process leaves no room for shortcuts. Our welding follows ISO 3834-2 standards, the global benchmark for fusion welding of metallic materials. Every arm-to-column joint is a full-penetration weld (not spot welding), inspected by certified welders and tested via ultrasonic flaw detection to ensure no hidden cracks. We use robotic welding for consistency on high-volume components, with manual touch-ups by skilled technicians for custom configurations.

For powder coating, we follow a 5-step pre-treatment process: degreasing, rinsing, phosphating, passivation, and drying. This removes contaminants and creates a porous surface that bonds with the powder, preventing chipping and peeling. The final powder coat is 80–100 microns thick (thicker than the industry average of 60 microns) and cured at 180°C for 20 minutes, creating a scratch-resistant finish that stands up to forklift impacts and industrial chemicals. We offer standard RAL colors (e.g., RAL 5010 blue, RAL 7035 gray) or custom colors to match your facility’s branding—all with the same rigorous application process.

4. “What is Your Recommended Anchoring Specification?”

A rack can’t be stable if it’s poorly anchored—and Herochu rejects “one-size-fits-all” solutions. Our engineering team calculates anchoring requirements based on three variables: rack height, total load per column, and floor concrete strength. For a 4m-tall rack supporting 12 tons per column on 200mm-thick concrete, we recommend M24x300mm galvanized anchor bolts (grade 8.8) spaced 300mm apart along the base plate. For shorter racks (2–3m) or lighter loads (3–5 tons), we may specify M20x200mm bolts—but only after verifying your floor’s compressive strength (via your facility’s construction documents or on-site testing).

We provide detailed anchoring drawings with every order, including torque specifications (typically 450 N·m for M24 bolts) and edge distance requirements (minimum 150mm from bolt to floor edge) to prevent concrete spalling. For outdoor installations or uneven floors, we offer adjustable base plates with slotted holes, letting you level the rack before final anchoring—ensuring stability even on imperfect surfaces.

5. “What Does Your After-Sales Support and Warranty Cover?”

Herochu’s relationship with you doesn’t end when the rack ships. Our after-sales package includes:

- Pre-delivery inspection videos: We send footage of your rack undergoing load testing (e.g., 125% of rated capacity for 24 hours) and quality checks, so you know it’s ready before it leaves our factory.

- Shipping damage support: If components arrive bent or scratched, we ship replacements within 48 hours—no paperwork delays.

- Installation assistance: Our team provides 24/7 phone support for your installers, plus detailed 3D assembly drawings. For international clients, we can arrange on-site installation by our certified technicians (available in 30+ countries, including the U.S., Germany, and Australia).

- 5-year warranty: Covers manufacturing defects (e.g., faulty welds, peeling coating) and structural failure under normal use. We even include a 1-year warranty on anchor bolts—something most suppliers exclude.

Beyond the warranty, we offer lifetime technical support: if your load requirements change in 10 years (e.g., you start storing heavier pipes), our engineers can design retrofits (e.g., reinforced arms, additional bracing) to upgrade your existing rack—saving you the cost of a full replacement.

Why Herochu’s New Heavy Duty Structural Cantilever Rack Stands Above the Rest

Generic suppliers sell steel; Herochu sells engineered systems. Our CE, EU, and ISO 9001 certifications aren’t just logos—they’re proof that we meet the strictest global standards for safety and quality. We answer your tough questions with documentation, not excuses. We use premium Q355B steel, weld to ISO standards, and customize anchoring to your floor. And we stand behind our racks with support that lasts as long as the product itself.

For the intelligent buyer—one who values safety, transparency, and long-term value—Herochu’s new heavy duty structural cantilever rack is the only choice. Whether you’re storing rebar in a construction yard, laser-cut plates in a manufacturing facility, or wiring spools in a distribution center, our rack is built to handle your load, protect your team, and maximize your storage efficiency.

Ready to work with a supplier who answers the hard questions? Contact Herochu today to request a stamped engineering quote, verify our steel grades, or schedule a video tour of our manufacturing facility.