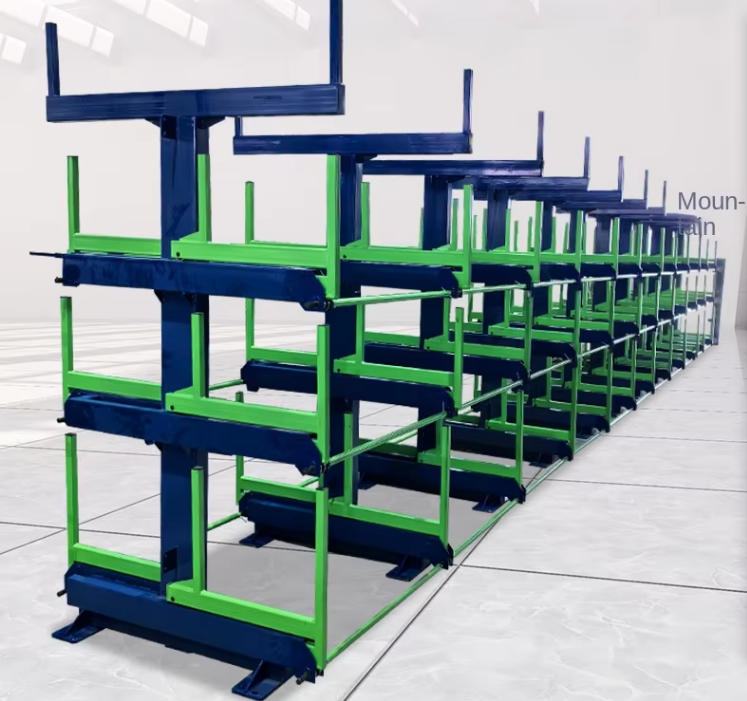

Herochu New & Used Cantilever Rack Systems – Buy It Once, Expand It Forever

Walk into any job shop that cuts, bends or welds long stock and you will see the same scene: bars, tubes and plates scattered like pick-up sticks across the floor, waiting for a forklift to hunt, lift and hope nothing topples. Herochu New & Used Cantilever Rack Systems erase that chaos in an afternoon. Starting at three thousand nine hundred and eighty-nine dollars for a four-foot starter bay, every column is CE-, UE- and ISO 9001-certified and can be unplugged, re-pinned or re-spaced as your inventory changes shape. Buy new for a green-field plant, buy used to stretch a tight budget, or mix both in the same aisle—our arms, braces and bases are dimensionally identical across generations, so yesterday’s frames accept tomorrow’s upgrades without a cutting torch.

The design is almost stubbornly simple: a vertical column, two horizontal arms and a welded base form an open-front shelf that welcomes long, awkward or heavyweight stock a pallet rack simply cannot swallow. Yet inside that simplicity hides a modular ecosystem that can grow from a single beer-budget bay to a fifty-metre, crane-served corridor handling 5 t loads per level. Whether you store twenty-foot structural beams, six-tonne aluminium plates or a forest of six-inch stainless bar, the rack adjusts before your coffee cools.

Columns roll from 5 mm hot-rolled coil, laser-cut for the arm pin holes and robot-welded to a 10 mm base plate that sits flush on any concrete floor. Arms are formed from 6 mm C-channel, taper-cut at the tip so a forklift driver sees daylight instead of steel when he slides in a bundle. Choose light series (500 kg per arm), medium series (1.2 t) or heavy series (2.5 t) and mix them on the same column—no one insists that level three must carry the same load as level one. Arms adjust on a 76 mm pitch, so you can store 250 mm channel on Monday and 600 mm plate on Tuesday by tugging five pins and a brace.

The open-front philosophy kills the “shuffling” tax. A bundle placed on a cantilever arm is instantly visible, measurable and reachable from three sides. Need the fifth bar from the left? Hook it, pull it, done—no pyramid dismantling, no re-stacking, no scratched edges that turn into expensive scrap. In high-mix, low-volume shops that service aerospace or architectural stainless, that single feature saves more money than the entire rack costs in its first month.

Space efficiency shows up in cubic metres, not square ones. A typical 1.5 m deep bay holds 4 t of bar stock in the footprint of a wooden pallet; go double-sided and you serve two aisles with one column, doubling density without doubling steel cost. Height is limited only by your crane or your ceiling—standard columns reach 6 m, but 8 m and 10 m masts ship regularly to ports in Houston and Hamburg. If you add a ceiling-mounted gantry later, the rack is already rated for the higher pick height; no structural reinforcement required.

Safety is engineered, not laminated on afterwards. Each arm accepts a removable steel pin that prevents accidental uplift during forklift withdrawal. A 125 mm high lip is welded at the tip, so a crooked bundle nudges itself back into line instead of skating off the edge. Columns arrive pre-drilled for horizontal X-bracing, turning a row of individual towers into a single rigid frame that resists seismic and forklift impact without the floor anchors typical pallet racks demand. Should you relocate, the braces unbolt and the entire bank travels like oversized Lego.

Buying used does not mean buying uncertainty. Every pre-owned component that enters our yard is mag-particle tested for cracks, shot-blasted to Sa 2.5 and re-coated in the same powder line as new steel. Arms are re-certified at 1.25 times rated load and sold with the same five-year structural warranty as virgin material. Paint colour may vary—some beams carry the battle scars of previous logos—but the metallurgy and the mechanical specs are identical. Budget-conscious customers often purchase one used bay to solve an immediate bottleneck, then add new extensions six months later when the capital request is approved. The bolt holes line up perfectly, and the accountant sees a single depreciation line.

Accessorise until the rack disappears and the system emerges. Install deck plates and create solid shelves for plywood or composite panels. Bolt on coil saddles and store slit coils nose-in without a mandrel. Clip on divider tubes and segregate ten-foot bars by alloy grade. Add a front cantilever mezzanine and turn the top levels into hand-pick slow movers while the lower arms feed the saws. If your product mix drifts from bar to plate to coil and back again, the same uprights re-configure in an afternoon while the coffee machine is still hot.

Integration with automation is no longer a futuristic footnote. We now supply arms with embedded RFID antennas that log bundle ID, weight and location every time a forklift sets material down. The data feeds directly to most ERP and MES platforms, so your purchasing manager knows the exact metre-count of 50 × 50 mm mild steel angle before he opens his spreadsheet. For lights-out operations, a guided vehicle can slide forks straight into the open front, retrieve a labelled bundle and deliver it to a saw or laser load table without human touch. The rack becomes a node in the factory nervous system instead of a dumb steel skeleton.

Freight logic follows the same modular mindset. Columns nest inside one another, arms stack like chairs, and braces bundle into tight cubes, so a forty-foot container swallows up to forty tonnes of rack hardware. Whether you need one bay or one hundred, the landed cost per kilo stays flat because we fill the cube before we quote the freight. Local assembly requires only a socket set and a torque wrench—no welding, no shot-fire anchors, no building permit in most jurisdictions. A two-bay starter can be standing upright and loaded within ninety minutes of the pallet hitting the floor.

Return on investment arrives the first time a forklift driver pulls a single six-metre bar in thirty seconds instead of spending twenty minutes un-stacking and re-stacking. Multiply that event by three jobs per day, two shifts per day, two hundred and fifty days per year and the labour saving alone pays for an average rack in under four months. Factor in reduced material damage, reclaimed floor space and lower insurance exposure and the pay-back drops below one fiscal quarter. After that, the rack keeps printing savings for decades because the steel does not obsolesce—only the paint fades.

Herochu has shipped New & Used Cantilever Rack Systems to ports, plants and prefab yards in forty-six countries. We keep new stock on the ground in Qingdao and used inventory in Rotterdam and Houston, so a replacement arm or an extra brace is never more than a few days away. Whether you are a one-man job shop wrestling with twenty-foot bar or a multinational bridging continents with structural beam, we build the rack that lets you see what you own, reach what you need and scale when you grow. Buy it once, bolt it together, load it heavy, and forget it exists—until the day you measure how much money it has saved.