Advanced Sheet Metal Palletizing Robot for Efficient Automation Solutions

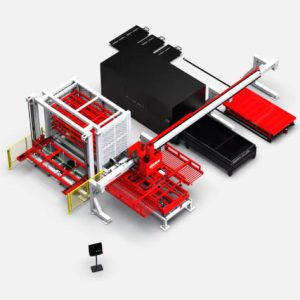

The Herochu Palletizing Robot, also known as a Column or Linear Robot, is a three-axis system developed to meet the rigorous demands of industrial environments. Its robust construction guarantees exceptional performance under continuous operation.

|

STANDARD

|

HC-R3015-500

|

HC-R3015-750

|

HC-R3015-1000

|

HC-R4020-500

|

HC-R4020-750

|

|

Thickness of feeding plate

|

8mm

|

12mm

|

20mm

|

8mm

|

12mm

|

|

Maximum feeding width

|

3000*1500mm

|

4000*2000mm

|

|||

|

Minimum feeding width

|

1250*1000mm

|

1250*1000mm

|

|||

|

Maximum plate weight

|

300kg

|

500kg

|

1000kg

|

300kg

|

500kg

|

|

Number of suction cups

|

15

|

15

|

118

|

15

|

15

|

|

Suction cup diameter

|

150mm

|

200mm

|

250mm

|

150mm

|

200mm

|

|

Power mode

|

Electric

|

||||

Herochu Advanced Sheet Metal Palletizing Robot: The Pinnacle of Automated Efficiency

In the relentless pursuit of industrial excellence, operational efficiency is the cornerstone of profitability and growth. Manual handling of sheet metal, a process fraught with inefficiency, potential injury, and significant variable costs, represents a critical bottleneck for modern manufacturing and fabrication workshops. Herochu addresses this fundamental challenge head-on with our Advanced Sheet Metal Palletizing Robot. This state-of-the-art automation solution is engineered to liberate your workforce from monotonous and physically demanding tasks, transforming your material handling operations into a model of precision, speed, and reliability.

As a cornerstone of industrial automation, the Herochu Palletizing Robot is designed to seamlessly integrate into your production line, performing the critical tasks of workpiece classification, transportation, loading, and unloading with unwavering consistency. This system is far more than a simple machine; it is a strategic investment designed to elevate your operational capabilities, reduce direct labor costs, and minimize production cycle times. By automating the palletizing process, you gain a decisive competitive advantage, ensuring your workshop operates at its maximum potential, shift after shift.

Uncompromising Performance and Robust Engineering

The Herochu Palletizing Robot, also known as a Column or Linear Robot, is a three-axis system developed to meet the rigorous demands of industrial environments. Its robust construction guarantees exceptional performance under continuous operation.

-

Number of Axes: 3

-

Positioning Accuracy: ±0.5mm

-

Repeatability: ±3mm

-

Maximum Speed: 25 meters/minute

-

Carrying Capacity: ≤150kg

-

Scope of Work: Customizable from 3000mm to 48000mm to fit your specific workshop layout.

-

Single Sheet Thickness Range: Handles materials from 0.5mm to 4mm with precision.

Built with a focus on structural integrity and powerful load-bearing capabilities, this robot is perfectly suited for the loading and unloading of laser cutting machines and raw material plates, ensuring a smooth and uninterrupted flow of materials through your facility.

Key Advantages of Integrating the Herochu Automation Solution

Our engineering philosophy prioritizes not only raw performance but also practical, day-to-day operational benefits.

-

Space-Optimized Design: Engineered with a minimal footprint, our robot maximizes your valuable floor space, allowing for efficient workshop planning without compromising on capability.

-

Simplified Structure, Superior Strength: The straightforward mechanical design translates to exceptional durability and a formidable load capacity of up to 150kg, ensuring long-term reliability and reduced risk of mechanical failure.

-

Ease of Maintenance and Operation: We believe powerful technology should be accessible. The Herochu robot features an intuitive control system and a simplified architecture that minimizes maintenance requirements and simplifies troubleshooting, keeping your downtime to an absolute minimum.

-

Multi-Station Operational Flexibility: A single Herochu robot can efficiently service the loading and unloading needs of up to three separate workstations, maximizing your return on investment and streamlining complex workflows.

-

Standard Automatic Splitting System: This integrated feature ensures flawless and automated separation of sheets, facilitating a smooth and continuous material feed without manual intervention.

-

Seamless System Integration: The robot is designed for compatibility and can be effectively used alongside a manual sheet material library, providing a flexible automation upgrade path for workshops of all sizes.

A Strategic Investment in Safety and Productivity

Beyond efficiency gains, the Herochu Palletizing Robot fundamentally enhances workplace safety. It expertly replaces human operators in handling potentially dangerous materials, thereby significantly reducing the risk of workplace accidents and ensuring compliance with stringent health and safety regulations. This allows your skilled workforce to be redeployed to higher-value, cognitive tasks that drive innovation and quality, fostering a safer and more engaging work environment.

Certified Quality and Customizable Automation

Your trust and safety are our highest priorities. Every Herochu Advanced Sheet Metal Palletizing Robot is CE and UE certified, guaranteeing compliance with European health, safety, and environmental protection standards. Furthermore, our manufacturing processes are certified under the ISO 9001 quality management system, a testament to our unwavering commitment to excellence and consistent quality in every product we deliver.

Understanding that no two workshops are identical, the Herochu solution is fully customizable. Starting at $20,200, we provide a scalable automation platform that can be tailored to your specific production requirements, product types, and spatial constraints. This flexibility allows you to quickly adjust to changing market demands, expand production capacity with ease, and future-proof your operations.

Embrace the future of manufacturing. Contact the Herochu team today to schedule a consultation and discover how our Advanced Sheet Metal Palletizing Robot can become the driving force behind your automated, intelligent, and unmanned operational success.

Q1: What steps should I take to start the procurement process?

Q2: How can I inform you of my need for suitable shelves?

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

Q4: Do you offer on-site installation and debugging services?

Q5: What measures do you take to ensure product quality?

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Q7: How can I verify your company’s strength?

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

PRODUCTS

-

Fiber Laser Automation Systems

Automation loading and unloading systems for Laser Processing Machines

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Fiber Laser Automation | Automatic Loading And Unloading

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Loading & Unloading Equipment Servo swing arm handling manipulator

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Advanced Sheet Metal Palletizing Robot for Efficient Automation Solutions

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Heavy Duty Roll Out Cantilever Pipe Storage Racks

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Laser Loading and Unloading Systems Suction Crane Vacuum Lifter for Sheet Metal

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Pneumatic Cantilever Manipulator Vacuum Lifter Crane

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Automatic Pipe Storage Racks Automated Profile Storage Warehouse Systems

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Roll Out Cantilever Pipe Storage Rack

Read moreRated 0 out of 5