Advanced sheet metal storage rack systems

For facilities constrained by floor space, vertical sheet metal storage racks offer a transformative solution. By storing sheets upright, these systems exploit the often-underutilized vertical cube of a warehouse, freeing up valuable square footage for production machinery or additional work-in-process areas. The primary advantage of a well-designed vertical system is its ability to provide individual access to each sheet. Unlike horizontal stacks, where retrieving one plate requires moving several others, vertical racks allow operators to target a specific sheet instantly. This is typically achieved through a tilting or partitioning mechanism that securely holds sheets in place while allowing for easy insertion and removal.

Reengineering Material Flow: The Strategic Advantage of Advanced Sheet Metal Storage Rack Systems

Within the high-stakes environment of modern manufacturing and metal fabrication, the storage of raw materials is seldom viewed as a strategic function. Often treated as a necessary evil, sheet metal storage can, in fact, become the most significant bottleneck in a production cycle. Inefficient handling of large, costly sheets of steel, aluminum, and other metals leads to tangible losses: time wasted retrieving specific plates, space consumed by disorganized stacks, and capital eroded through surface damage and edge deformation. The transition from conventional stacking to advanced sheet metal storage rack systems represents a fundamental shift from passive storage to active inventory management. These engineered systems are not merely shelving; they are a core component of a lean manufacturing philosophy, designed to protect valuable assets, optimize workflow, and unlock latent capacity within a facility. For any operation where material handling impacts the bottom line, the implementation of a sophisticated storage solution is a critical decision.

The Limitations of Conventional Methods and the Case for Engineering

Traditional storage methods, primarily horizontal stacking on the floor or on basic racks, impose severe limitations on operational efficiency. The act of retrieving a single sheet from the middle of a stack requires significant crane or forklift intervention, a time-consuming process that risks damaging the material below. This approach creates an inherent conflict between inventory density and accessibility. Furthermore, the inability to easily identify or inspect individual sheets fosters disorganization, leading to production delays and potential errors in material selection. The physical strain on both the materials and the equipment accelerates wear and tear, increasing operational costs. Advanced sheet metal storage rack systems are conceived to dismantle these inefficiencies. By applying principles of mechanical engineering and ergonomic design, they transform chaotic storage areas into organized, high-throughput zones that integrate seamlessly with material handling workflows.

Vertical Systems: Maximizing Cubic Space and Accessibility

For facilities constrained by floor space, vertical sheet metal storage racks offer a transformative solution. By storing sheets upright, these systems exploit the often-underutilized vertical cube of a warehouse, freeing up valuable square footage for production machinery or additional work-in-process areas. The primary advantage of a well-designed vertical system is its ability to provide individual access to each sheet. Unlike horizontal stacks, where retrieving one plate requires moving several others, vertical racks allow operators to target a specific sheet instantly. This is typically achieved through a tilting or partitioning mechanism that securely holds sheets in place while allowing for easy insertion and removal.

High-performance vertical systems feature robust structural frames constructed from high-tensile steel, with adjustable arms or dividers to accommodate a wide range of sheet sizes and thicknesses. A critical design element is the inclusion of a slight backward tilt, which ensures that the weight of the sheet is directed into the rack’s structure, preventing accidental tipping and enhancing safety. This configuration is particularly beneficial for handling delicate or pre-finished materials, such as stainless steel or brushed aluminum, where even minor scratches can result in costly rejections.

Heavy-Duty Roll-Out Racks: The Pinnacle of Handling Efficiency

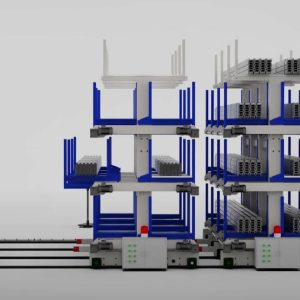

Where accessibility and handling frequency are paramount, roll-out sheet metal racks represent the pinnacle of storage technology. Functioning like heavy-duty drawers, these systems are mounted on precision bearing rollers or tracks, allowing an entire rack loaded with tons of material to be extended smoothly and safely into the aisle. This design provides unfettered access to the entire face of the stored sheets, enabling overhead cranes or vacuum lifters to position themselves optimally for secure lifting. The ergonomic benefit is profound; it eliminates the dangerous and inefficient practice of operators leaning into racks or trying to maneuver sheets out of tight spaces.

The engineering behind these systems is substantial. Each roll-out carriage is built to handle extreme loads, often up to several tons per compartment, with reinforced steel frames and industrial-grade rollers. Safety interlocks and integrated braking systems prevent accidental movement or over-extension, ensuring stability during operation. For large-format plates, such as the standard 3,000×2,000mm sheets common in many fabricating shops, roll-out racks drastically reduce retrieval times from minutes to seconds, directly accelerating production cycles and improving asset utilization.

Customization as a Standard: Tailoring the System to the Workflow

A fundamental truth in industrial storage is that no two workshops are identical. A system that works perfectly in one facility may be entirely unsuitable in another due to variations in plate dimensions, material handling equipment, workflow patterns, and floor space constraints. Therefore, the most critical feature of any advanced storage system is its inherent customizability. The Herochu philosophy is that customization is not an optional extra but a standard requirement. Our advanced sheet metal storage rack systems are engineered to be modular and adaptable. Key parameters such as overall height, depth, compartment width, and load capacity are not fixed; they are variables defined by the client’s specific needs.

This tailored approach ensures that the storage system acts as a natural extension of the production process. Whether the requirement is for a vertical system to conserve space in a compact laser cutting cell or a series of heavy-duty roll-out racks for a high-volume plasma cutting line, the solution is configured from the ground up. This includes considerations for integration with existing overhead cranes, forklift routes, and even future expansion plans. Starting at an accessible price point of $2,280, this bespoke engineering makes advanced storage a viable and high-return investment for businesses of various scales.

Certification and Quality: The Foundation of Operational Integrity

In an industrial setting, where worker safety and asset protection are non-negotiable, the pedigree of equipment is everything. Herochu advanced sheet metal storage rack systems are designed and manufactured under the most rigorous quality assurance protocols, evidenced by our CE, EU, and ISO 9001 certifications. These certifications are not merely badges; they are a guarantee of a systematic commitment to safety, durability, and performance. The ISO 9001 standard, in particular, governs every stage of production, from initial material selection and structural design calculations to welding procedures and final assembly. This ensures that every rack that leaves our facility is capable of performing reliably under the demanding conditions of daily industrial use, providing peace of mind and a solid foundation for operational integrity.

From Storage Burden to Competitive Asset

The decision to invest in an advanced sheet metal storage rack system is a strategic move to convert a perennial operational burden into a tangible competitive advantage. The returns are measured in quantifiable terms: the reclamation of valuable floor space, the elimination of material damage costs, the dramatic reduction in retrieval times, and the enhancement of workplace safety. By organizing and protecting valuable inventory, these systems bring a new level of control and efficiency to the shop floor. To explore how a customizable Herochu storage solution can be engineered to meet the unique demands of your workshop, we invite you to contact our engineering team for a detailed consultation. Let us help you transform your material handling workflow from a source of cost into a driver of productivity.

Q1: What steps should I take to start the procurement process?

Q2: How can I inform you of my need for suitable shelves?

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

Q4: Do you offer on-site installation and debugging services?

Q5: What measures do you take to ensure product quality?

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Q7: How can I verify your company’s strength?

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

PRODUCTS

-

Heavy Duty Cantilever Racking System

Long Goods Heavy Duty Cantilever Rack

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

New & Used Cantilever Racks | Heavy-Duty Storage Systems

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Heavy Duty Cantilever Racking System & Shelves

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Heavy-Duty Steel Plate Organizer Shelf Drawer-Type Sheet Storage racks

Read moreRated 0 out of 5