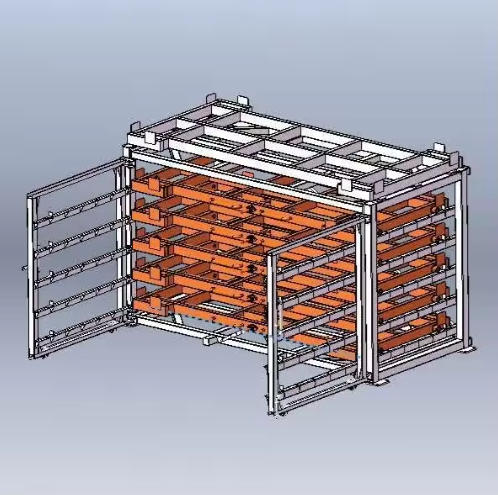

Automatic sheet metal storage tower for Fiber Laser cutting

The Herochu Automatic Sheet Metal Storage Tower represents a fundamental reimagining of this dynamic. This is not merely a storage unit; it is a high-density, automated vertical warehouse engineered to integrate seamlessly with your fiber laser cutting system. By moving storage upward into a compact footprint, the system directly addresses the critical pain point of space occupation. It replaces wide, inaccessible stacks with a towering structure that can hold a vast inventory of sheet metal in a fraction of the area. This three-dimensional storage philosophy is the key to unlocking the full value of your workshop’s square footage. The space you save can be repurposed for additional value-added operations, new production lines, or simply to create a safer, more organized working environment.

In the contemporary manufacturing landscape, the fiber laser cutting machine stands as a pinnacle of speed and precision. However, its potential is often constrained not by its own capabilities, but by the logistical challenges that surround it. The traditional method of storing sheet metal—characterized by sprawling floor stacks and disorganized racks—creates a significant bottleneck that undermines the very efficiency the laser cutter is meant to provide. This approach consumes a prohibitive amount of valuable factory floor space, complicates inventory management, and forces skilled operators to perform the tedious and physically demanding work of material handling. The result is a production cell where the non-cutting time, the time spent searching for and moving raw materials, becomes an unacceptable drain on productivity and profitability.

The Herochu Automatic Sheet Metal Storage Tower represents a fundamental reimagining of this dynamic. This is not merely a storage unit; it is a high-density, automated vertical warehouse engineered to integrate seamlessly with your fiber laser cutting system. By moving storage upward into a compact footprint, the system directly addresses the critical pain point of space occupation. It replaces wide, inaccessible stacks with a towering structure that can hold a vast inventory of sheet metal in a fraction of the area. This three-dimensional storage philosophy is the key to unlocking the full value of your workshop’s square footage. The space you save can be repurposed for additional value-added operations, new production lines, or simply to create a safer, more organized working environment. This transformation from a crowded storage area to a streamlined, automated material hub is the first step toward creating a truly modern and efficient manufacturing process.

At the core of the Herochu Storage Tower is a sophisticated automation system controlled by a programmable logic controller (PLC). This technology elevates material handling from a manual chore to a precise, one-person operation. Through an intuitive control interface, an operator can command the system to retrieve or store a specific sheet from any level with simple instructions. The machinery responds with reliable accuracy, utilizing a robust chain drive transmission system to vertically position the required shelf. With a vertical lifting speed of nine meters per minute, the system ensures swift cycle times, dramatically accelerating the raw material turnover and keeping your fiber laser cutter actively engaged. This precision eliminates the guesswork and physical strain associated with manual retrieval, virtually eliminating the risk of sheet damage and workplace injury while ensuring that the correct material is delivered every time.

The true power of this automation is realized in its ability to create a connected production cell. The Herochu Automatic Storage Tower is designed for seamless integration with your fiber laser cutter and other automation equipment. This synergy facilitates an uninterrupted flow of materials, where a sheet is retrieved from the tower and automatically fed into the laser machine with minimal human intervention. This capability is a cornerstone for businesses aiming to establish automated processing cells or even pursue “lights-out” manufacturing operations, where production can continue safely and efficiently outside of normal working hours. For companies operating a flexible production model with multiple product varieties and small batch sizes, this system provides the necessary management flexibility and high-frequency access to stay competitive.

Herochu understands that a one-size-fits-all solution is insufficient for the diverse needs of modern industry. Our Automatic Sheet Metal Storage Tower is built with customization as a core principle. Based on the model HC-S6015-125, which accommodates plates up to 6000x1500mm across ten layers, we offer extensive customization to align with your workshop’s specific requirements. This includes tailoring the number of layers, the distance between them, load-bearing capacity, and optional plate support systems to protect sensitive materials. With a starting investment of $5,000, this advanced automation is an accessible and strategic upgrade for a wide range of enterprises. Furthermore, the entire system is CE, EU, and ISO 9001 certified, providing assurance that the equipment meets rigorous international standards for safety, quality, and performance. By implementing the Herochu Automatic Sheet Metal Storage Tower, you are not just organizing your inventory; you are installing a dynamic, intelligent component that elevates your entire fiber laser cutting operation to new levels of productivity, safety, and control.

Q1: What steps should I take to start the procurement process?

Q2: How can I inform you of my need for suitable shelves?

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

Q4: Do you offer on-site installation and debugging services?

Q5: What measures do you take to ensure product quality?

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Q7: How can I verify your company’s strength?

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

PRODUCTS

-

Sheet Metal Storage Racks

High-Capacity Vertical Sheet Racks for Organized Storage Needs

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Heavy-Duty Vertical Roll-out Sheet Racks for Steel Scrap

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Automatic Sheet Metal Storage Systems for Fiber Laser Cutters

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Automatic sheet metal storage tower for Fiber Laser cutting

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

The Sheet Steel Rack Solution for Optimized Warehouse Storage

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Maximize Warehouse Space: A Guide to Sheet Steel Storage Racks

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Automatic Storage System for Long Material

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Heavy Duty Sheet Metal Storage Racks of Warehouse

Read moreRated 0 out of 5