Automatic Steel Plate Storage Racking System

Herochu’s system isn’t a repurposed generic rack—it’s a specialized solution built on the backbone of advanced automated pallet racking technology, reengineered for steel plates. At its core, the system combines three key components to deliver seamless operation

Specification

|

Specification

|

3015/4015/4020/6015/6020/6025mm

|

|

Number of floor

|

8-13

|

|

Load per layer

|

3T/5T

|

|

Mode of movement

|

Linear guide rail + chain

|

|

Transmission mode

|

Chain drive

|

|

Vertical lifting Speed

|

9m/min

|

|

Inlet and outlet Speed

|

12m/min

|

|

Plate Support

|

optional selection

|

Herochu Automatic Steel Plate Storage Racking System: Industrial-Grade Automated Solution

For manufacturing facilities, metal fabrication shops, and warehouses managing large volumes of steel plates—whether raw, partially cut, or finished—storage inefficiency is more than an inconvenience. It’s a barrier to productivity: manual handling slows retrieval, generic racks waste space, and mismanaged inventory leads to costly delays or damage. Herochu’s Automatic Steel Plate Storage Racking System redefines how businesses store and access steel plates, merging the precision of automated pallet racking technology with robust design tailored for heavy, bulky steel. Starting at $19,999 and backed by CE, EU, and ISO 9001 certifications, this system delivers 24/7 reliability, space optimization, and productivity gains of 40–60%—making it the ideal choice for operations scaling up or streamlining their steel handling workflows.

Certified Durability for Heavy Steel Plate Storage

Steel plates demand a storage system built to handle their weight, size, and rigidity—and Herochu’s Automatic Steel Plate Storage Racking System doesn’t just meet those demands; it exceeds them. With CE, EU, and ISO 9001 certifications, every component—from the vertical storage frames to the robotic retrieval mechanisms—undergoes rigorous testing to ensure structural integrity and operational safety. This isn’t just compliance; it’s a promise that the system can support steel plates of all thicknesses (from thin gauge to 50+ mm) and sizes (up to 4,000 mm x 2,000 mm) without bending, warping, or failing. For facilities operating in regulated industries—like automotive, construction, or heavy equipment manufacturing—these certifications eliminate compliance risks and provide peace of mind that both workers and inventory are protected.

How Automated Pallet Racking Tech Powers Steel Plate Storage

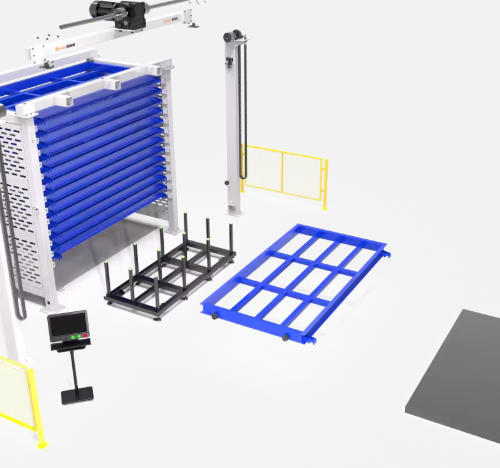

Herochu’s system isn’t a repurposed generic rack—it’s a specialized solution built on the backbone of advanced automated pallet racking technology, reengineered for steel plates. At its core, the system combines three key components to deliver seamless operation:

- Robotic Shuttles & Automated Guided Vehicles (AGVs): These precision tools handle the heavy lifting—literally. Unlike manual forklifts that risk dropping or scratching steel plates, robotic shuttles glide along integrated rails to retrieve or store plates with millimetric accuracy. AGVs complement this by transporting plates between the racking system and production machines (like laser or plasma cutters), eliminating the need for human operators to move heavy loads.

- Computerized Warehouse Management System (WMS): The system’s brain, the WMS coordinates every movement in real time. It tracks inventory levels, assigns optimal storage locations (to maximize space), and plans retrieval routes (to minimize wait times). For example, if a laser cutter needs a 3 mm stainless steel plate for a rush order, the WMS instantly locates the plate, sends a signal to the robotic shuttle, and updates inventory counts as soon as the plate is retrieved—no manual data entry required.

- Vertical Storage Frames with Integrated Lifting Mechanisms: Steel plates take up massive floor space when stored horizontally. Herochu’s vertical frames turn unused overhead space into storage capacity, with multiple levels of racking that can be configured as single-deep, double-deep, or multiple-deep. This design typically increases storage capacity by 30–50% compared to traditional racks—critical for facilities with limited square footage.

The Objectives That Drive Every Design Choice

Herochu’s Automatic Steel Plate Storage Racking System is built to solve four core challenges facing steel-intensive operations: boosting productivity, optimizing space, protecting inventory, and enabling 24/7 operation. Here’s how it delivers on each:

1. Boost Productivity by 40–60%

Manual steel plate handling is slow, labor-intensive, and error-prone. A single worker might take 15 minutes to locate and move a heavy plate to a cutting machine—time that adds up over a shift. Herochu’s system cuts that retrieval time to 60 seconds or less, thanks to automated shuttles and real-time WMS tracking. But the gains don’t stop there: the system acts as a buffer for cutting machines, storing partially cut plates until they’re fully consumed. This means machines never sit idle waiting for material—they run continuously, increasing overall productivity by 40–60%. Some Herochu customers have even reported 90%+ productivity improvements when pairing the system with turntable feeding systems.

2. Maximize Space Without Expanding Your Facility

Floor space is a premium in most workshops, and steel plates are notorious for taking up too much of it. Herochu’s vertical storage design changes that. By stacking plates upward instead of outward, the system turns 100 square feet of floor space into enough storage for 50+ plates (depending on size and thickness)—a 30–50% increase in capacity compared to traditional horizontal racks. For example, a facility that previously stored 200 3,000 mm x 1,500 mm plates across 200 square feet can now store 300+ plates in the same space—freeing up room for additional cutting machines or workflow expansion.

3. Protect Steel Plates from Damage

Steel plates are valuable, but they’re also vulnerable to scratches, dents, or bending if handled improperly. Herochu’s system eliminates these risks with gentle, consistent handling: robotic shuttles grip plates from the sides (avoiding pressure on delicate surfaces), and the WMS ensures plates are stored in stable, secure positions. Even partially cut plates—often the most fragile—are protected, as the system stores them in dedicated compartments until they’re ready for further processing. This reduces damage rates by up to 70%, cutting down on wasted material and costly reorders.

4. Enable 24/7 Operation (No Human Limits)

Manufacturing doesn’t stop at 5 PM—but manual labor does. Herochu’s Automatic Steel Plate Storage Racking System operates around the clock, with no breaks or shifts. The automated shuttles, AGVs, and WMS work together to handle storage and retrieval even when the workshop is empty, so morning shifts start with machines pre-loaded and inventory ready. This is a game-changer for facilities with tight deadlines or global clients who require 24-hour production cycles.

Configurations Tailored to Your Steel Handling Needs

Herochu knows no two steel operations are the same—so the system offers flexible configurations to match your workflow, equipment, and space:

1. Storage Towers with Rail Systems

Ideal for facilities with multiple cutting machines, storage towers are paired with optional rail systems that let robotic shuttles service up to 5 towers at once. This setup acts as a central “hub” for steel plates, feeding material to laser, plasma, or oxyfuel cutters as needed. The towers also provide an ergonomic working height for loading/unloading—reducing worker strain and improving safety. For example, a shop with 3 Messer laser cutters (each with different process capabilities) can use the rail system to ensure the right plate is delivered to the right machine, with the WMS tracking which process is needed for each job.

2. In-Line Shuttles with Mini-Storage Towers

For smaller facilities or those with limited overhead space, in-line shuttles paired with mini-storage towers offer a compact solution. The mini-towers act as a buffer for part unloading—so when a cutting machine finishes a plate, the shuttle moves the partially cut piece to the tower instantly, letting the machine start on the next plate without waiting. Optional noise and light abatement enclosures make this configuration perfect for workshops where worker comfort is a priority.

3. Turntable Feeding Systems

Traditional in-line storage forces facilities to arrange machines in a straight line—but turntables break that mold. They let storage towers and cutting machines be placed in nonlinear layouts, so you can design your workshop around production flow (not the racking system). Turntables also let multiple machines share a single storage system: for example, two laser cutters can pull plates from the same tower, maximizing equipment utilization and reducing costs. This flexibility is especially valuable for shops with irregularly shaped floors or growing equipment fleets.

Full Customization: Build the System Your Workshop Needs

Herochu doesn’t just offer configurations—we offer full customization. Every aspect of the Automatic Steel Plate Storage Racking System can be adjusted to fit your unique needs:

- Load Capacity: Increase shelf strength to handle plates up to 2,000 kg per unit (ideal for thick, heavy steel).

- Storage Depth: Choose single-deep (for frequent access) or multiple-deep (for bulk storage of rarely used plates).

- Integration: Sync the WMS with your existing ERP system (like SAP or Oracle) for end-to-end supply chain tracking, or add compatibility with specific cutting machines (e.g., Trumpf, Amada, or Messer).

- Safety Features: Add motion sensors to prevent collisions, anti-slip surfaces for wet environments, or emergency stop systems for high-traffic areas.

- Aesthetics: Select industrial black, safety red, or custom colors to match your facility’s branding or safety protocols.

Whether you’re a small fabricator storing 100 plates or a large manufacturer managing 10,000+, Herochu’s team works with you to design a system that fits your budget, space, and long-term goals.

Why Herochu for Automatic Steel Plate Storage?

In a market flooded with generic automated racks, Herochu’s system stands out for three critical reasons:

- Specialization: It’s built exclusively for steel plates—unlike automated pallet racks repurposed for metal, which often fail under heavy loads or damage delicate surfaces.

- Proven Results: Customers see 40–60% productivity gains, 30–50% more storage space, and 70% less material damage—hard numbers that translate to lower costs and higher profits.

- Certified Reliability: CE, EU, and ISO 9001 certifications ensure the system meets global safety standards, so you’re not just investing in storage—you’re investing in peace of mind.

Don’t let manual steel plate storage hold your operation back. Herochu’s Automatic Steel Plate Storage Racking System turns slow, wasteful processes into fast, efficient ones—freeing up time, space, and resources to grow your business. Contact Herochu today to discuss your customization needs and find out if this solution is right for your workshop.

Q1: What steps should I take to start the procurement process?

You may get in touch with our backend technical staff first. Based on your specific parameters, we will formulate a suitable technical solution and provide a quotation. Alternatively, you can leave your contact details—such as WhatsApp, WeChat, or email address—and our professional sales team will reach out to you proactively.

Q2: How can I inform you of my need for suitable shelves?

You can share key information with us, including the type of items you plan to store on the shelves, the dimensions of those items, the quantity of shelves required, and any other specific details you have. With this information, we will develop a professional solution tailored to your needs. If you prefer, you can also leave your contact information, and our specialized team will contact you to address your questions.

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

To determine the right option, two key factors need to be considered first:

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

For a more accurate recommendation based on your specific needs, please leave your contact information, and we will provide targeted service.

Q4: Do you offer on-site installation and debugging services?

Yes, we do. We can dispatch professional technicians to your factory to carry out on-site installation and debugging of the robotic arm, and we will continue working until the equipment completes a successful trial operation. Our team has provided such services in many countries, including South Africa, the United States, Russia, South Korea, Qatar, Egypt, Lebanon, and Mexico.

Q5: What measures do you take to ensure product quality?

We have a comprehensive quality assurance system, supported by the following key measures:

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Our factory is located in Jinan, Shandong Province, China, specifically at No. 10 Industrial Park, Jiyang Street. It features a modern, standard workshop covering an area of 10,000 square meters.

Q7: How can I verify your company’s strength?

We offer two convenient ways for you to assess our company’s capabilities:

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

We are Jinan Constant Storage Machinery Manufacturing Co., Ltd., a high-tech enterprise that integrates research and development, production, sales, installation, and after-sales service. Our core product range includes intelligent sheet metal material warehouses, drawer-type sheet metal shelves, telescopic cantilever shelves, servo swing arm manipulators, gantry loading and unloading manipulators, fully automatic loading and unloading systems, and heavy-duty sheet metal and pipe storage shelves. Equipped with a professional technical team and advanced production equipment, we are committed to providing high-quality, high-performance mechanical products and customized solutions to customers around the world.

PRODUCTS

-

Heavy Duty Cantilever Racking System

Heavy Duty Telescopic Cantilever Storage System Metal Pipe Storage System Shelves

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Automatic Steel Plate Storage Racking System

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Automatic Pallet Racking System Solution Steel Shelf Metal Rack

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Pipe Store Long Span Goods Automated Storage System

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Manual Control Roll out Sheet Metal Rack with Forklift

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Pull Out Sheet Storage Drawer Rack Roll-Out Sheet Rack for Sheets

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Customizable Workshop Storage Cantilever Racking System

Read moreRated 0 out of 5