Automatic warehouses for sheet metal storage

The Herochu Automated Warehouse is engineered with a focus on robustness, precision, and adaptability. The system is available in a range of standard sizes to accommodate diverse workshop layouts and material requirements, including 3015, 4015, 4020, 6015, 6020, and 6025mm configurations. The structure typically features between 8 and 13 floors, with a formidable load capacity of 3 or 5 tonnes per layer, ensuring the secure storage of even the heaviest sheet metal packs.

|

Specification

|

3015/4015/4020/6015/6020/6025mm

|

|

Number of floor

|

8-13

|

|

Load per layer

|

3T/5T

|

|

Mode of movement

|

Linear guide rail + chain

|

|

Transmission mode

|

Chain drive

|

|

Vertical lifting Speed

|

9m/min

|

|

Inlet and outlet Speed

|

12m/min

|

|

Plate Support

|

optional selection

|

Herochu Automated Warehouses for Sheet Metal Storage: Engineering a New Era of Industrial Efficiency

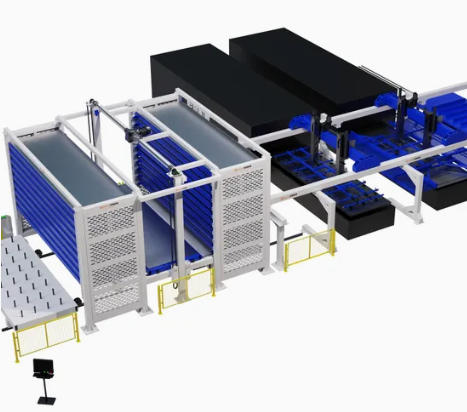

In the competitive landscape of modern manufacturing, the management of raw materials is not merely a logistical task—it is a critical determinant of overall productivity and profitability. For companies working extensively with sheet metal, the challenges of traditional storage methods are all too familiar: sprawling floor space consumption, labor-intensive handling, significant safety risks, and inefficient inventory control. These challenges create bottlenecks that impede workflow, increase operational costs, and limit scalability. It is to address these fundamental industrial pain points that Herochu introduces its series of Automated Warehouses for Sheet Metal Storage. This system represents a paradigm shift, transforming storage from a passive, space-consuming necessity into a dynamic, integrated component of your automated production line. As a turnkey solution customizable to the specific dimensions and throughput of your workshop, with configurations starting at $8,900, the Herochu automated warehouse is an accessible and transformative investment for forward-thinking fabricators. Every unit is CE, EU, and ISO 9001 certified, guaranteeing adherence to the highest international standards of safety, quality, and performance.

Precision Engineering and Configurable Specifications

The Herochu Automated Warehouse is engineered with a focus on robustness, precision, and adaptability. The system is available in a range of standard sizes to accommodate diverse workshop layouts and material requirements, including 3015, 4015, 4020, 6015, 6020, and 6025mm configurations. The structure typically features between 8 and 13 floors, with a formidable load capacity of 3 or 5 tonnes per layer, ensuring the secure storage of even the heaviest sheet metal packs.

The mechanism of movement is a cornerstone of its reliability, utilizing a combination of linear guide rails and a heavy-duty chain drive system. This pairing ensures smooth, precise, and unwavering alignment during all operations. The vertical lifting speed is a consistent 9 meters per minute, while the inlet and outlet speed reaches 12 meters per minute, creating a rapid and rhythmic flow of materials. The plate support system is offered as an optional selection, allowing for further customization to suit specific material types and sizes, ensuring optimal support and preventing deformation.

A Compact, High-Density Tower for Maximum Space Utilization

The Herochu system is a very compact tower storage system specifically engineered for storing sheet metal and other flat goods in the tightest of spaces close to production. Its primary advantage lies in its ability to optimize the often-underutilized vertical space within a facility. By using the room height to store sheet packs on an optimized stacking height, a single Herochu unit can provide up to 65 organized storage locations on a minimal footprint. This high-density approach liberates valuable floor space that can be repurposed for additional machinery, assembly operations, or other value-added activities, effectively increasing the functional capacity of your existing workshop without the need for physical expansion.

Seamless Integration and Operational Fluidity

A defining characteristic of the Herochu Automated Warehouse is its exceptional integration capability. These systems are highly customizable and easy to integrate into machine and plant environments. They can be configured as a single or double tower and set up free-standing in the immediate vicinity of processing machines like laser cutters or punching centers. This strategy of storage close to production drastically reduces the time, effort, and distance required for material movements, slashing internal logistics time and accelerating the entire production cycle.

Furthermore, various versions of the series can be easily connected to laser cutting machines or ERP systems from different manufacturers. This interoperability is a key strategic advantage; it allows for real-time data exchange, enabling better stock control and timely reordering of material to avoid shortages. The system’s modular design also means it can be expanded at a later date, for instance, with an additional tower or enhanced software interface, ensuring your investment grows in step with your business.

Intuitive Control and Ergonomic Material Access

Operational simplicity is at the core of the Herochu design. The system is easy to operate, even by non-specialist staff. An intuitive control interface features centrally located and logically designed operating elements. The process is straightforward: an operator simply selects the desired storage tray, and the system’s integrated lifting traverse does the rest. This lifting unit automatically transports the system pallets to an ergonomic working height, eliminating the need for strenuous bending, reaching, or the use of overhead cranes. This ergonomic access is not merely a convenience; it is a critical feature that promotes workforce well-being and prevents strain-related injuries.

Tangible Business Advantages and Return on Investment

The implementation of a Herochu Automated Warehouse delivers a comprehensive suite of benefits that directly impact the bottom line.

-

Increased Efficiency and Shorter Response Times: By optimizing material flow, the system ensures sheets are made available precisely when and where they are needed. This is particularly crucial for production environments with continuous material requirements and just-in-time needs, significantly shortening production cycles.

-

Failure Reduction and Improved Stock Management: Automation minimizes human error in the infeed and outfeed process, drastically reducing costly mistakes, material waste, and out-of-stock situations. The integrated warehouse management software provides real-time monitoring and tracking of sheet metal stocks, enabling unparalleled inventory accuracy.

-

Enhanced Work Safety: The system fundamentally improves worker safety by reducing or eliminating the manual handling of heavy, sharp-edged sheets. This proactive approach reduces the risk of injury and the associated human and financial costs.

-

Effective Use of Personnel and Reduced Costs: Automating the storage and retrieval process allows skilled labor to be redeployed to more value-added tasks such as programming, quality control, and machine operation. This alleviates labor shortages and maximizes the utility of your workforce. While the initial investment is significant, the long-term reduction in labor costs, combined with gains in efficiency and waste reduction, delivers a compelling and rapid return on investment.

-

Data Management for Continuous Improvement: The system continuously collects data on warehouse activities. This data can be analyzed to identify trends, predict future demand, and further optimize warehousing and production planning, fostering a culture of continuous operational improvement.

The Herochu Automated Warehouse for Sheet Metal Storage is more than a storage solution; it is a strategic asset that drives operational excellence. It represents a commitment to safety, efficiency, and intelligent manufacturing. By consolidating your sheet metal inventory into a secure, automated, and space-saving tower, you gain not just storage space, but a significant competitive advantage. To explore how a customizable Herochu system can be engineered to meet your specific operational requirements, we encourage you to contact our technical sales team for a detailed consultation.

Q1: What steps should I take to start the procurement process?

Q2: How can I inform you of my need for suitable shelves?

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

Q4: Do you offer on-site installation and debugging services?

Q5: What measures do you take to ensure product quality?

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Q7: How can I verify your company’s strength?

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

PRODUCTS

-

Sheet Metal Storage Racks

Industrial Shelving Systems for Heavy-Duty Sheet Metal Storage

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Efficient Heavy Duty Horizontal Sheet Metal Storage Rack System

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Automatic warehouses for sheet metal storage

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Cantilever Pneumatic Arm Manipulator

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Estanterias cantilever | Scaffalature cantilever

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Prateleira cantilever racking supplier

Read moreRated 0 out of 5