Choosing the Right Sheet Steel Storage Rack for Maximum Space Efficiency & Organization

Closely tied to space is the Convenience of Operation. The ease with which materials can be stored and retrieved has a direct and significant impact on workflow efficiency and labor costs. Traditional stacking methods often require moving multiple items to access a single sheet, a time-consuming and potentially hazardous process. A well-engineered horizontal rack transforms this dynamic. The ideal system enables true single-person operation, where an employee can access any specific sheet without assistance. This is typically achieved through a series of fully extendable, heavy-duty drawers that bring the entire sheet into the open for safe and easy handling with a crane or vacuum lifter. This design eliminates repetitive, non-value-added work and accelerates material flow to production lines.

|

Standard

|

HC-B3015-63

|

HC-B4015-63

|

HC-B4020-65

|

HC-B6020-65

|

|

Plate size

|

3000*1500mm

|

4000*1500mm

|

4000*2000mm

|

6000*2000mm

|

|

Number of layers

|

6

|

6

|

6

|

6

|

Choosing the Right Sheet Steel Storage Rack for Maximum Space Efficiency & Organization

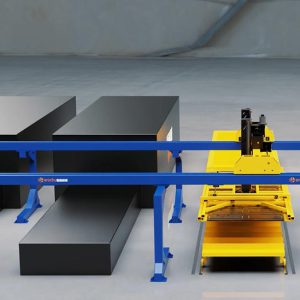

As operational scale increases and storage demands intensify, the selection of an appropriate racking system becomes a strategic decision with far-reaching consequences for productivity and profitability. For facilities in the manufacturing and construction sectors that manage substantial inventories of sheet materials—including metal, wood panels, and gypsum board—the horizontal sheet steel storage rack has emerged as a preferred solution. Its reputation is built on a foundation of exceptional space utilization, operational simplicity, and a proven ability to minimize product damage. However, identifying the optimal system for your specific needs requires a careful evaluation of several critical factors beyond the basic specification sheet. An informed selection process, focusing on the following five areas, will ensure your investment delivers maximum value, enhances organization, and supports long-term growth.

The first and perhaps most pressing consideration is Space Efficiency. The primary objective of any specialized storage system is to store more material within the same footprint, thereby increasing storage density. A high-quality rack must offer a flexible design that maximizes not only horizontal space but, more importantly, vertical clearance. The ability to adjust the number of tiers and the height between each layer is paramount. This adaptability allows you to tailor the storage configuration to the exact dimensions of your sheet stock, ensuring no cubic inch of your warehouse volume is wasted. Furthermore, the system must conform to your existing warehouse structure, accounting for column placements, necessary aisle widths, and ceiling height. A truly efficient rack integrates seamlessly into the available space rather than forcing a compromise in your layout.

Closely tied to space is the Convenience of Operation. The ease with which materials can be stored and retrieved has a direct and significant impact on workflow efficiency and labor costs. Traditional stacking methods often require moving multiple items to access a single sheet, a time-consuming and potentially hazardous process. A well-engineered horizontal rack transforms this dynamic. The ideal system enables true single-person operation, where an employee can access any specific sheet without assistance. This is typically achieved through a series of fully extendable, heavy-duty drawers that bring the entire sheet into the open for safe and easy handling with a crane or vacuum lifter. This design eliminates repetitive, non-value-added work and accelerates material flow to production lines.

A third critical factor is Sheet Protection. Sheet materials, particularly metal, glass, and finished wood products, are highly susceptible to scratching, bending, and edge damage when improperly stored. The horizontal storage method is inherently superior for material preservation. By storing sheets flat and supported along their entire length, these racks eliminate the point pressures and friction that occur in vertical stacks or leaning configurations. This approach significantly reduces surface abrasion and prevents the warping or deformation that can render expensive materials unusable. Protecting your inventory from damage is not just a matter of reducing waste; it is a direct contributor to maintaining consistent quality in your end products and controlling replacement costs.

Flexibility and Scalability are also essential qualities in a dynamic industrial environment. The variety of materials, sizes, and weights handled by a single facility can be vast. A rigid, one-size-fits-all rack quickly becomes a limitation. Therefore, the chosen system should boast a modular design, allowing for reconfiguration as needs change. The capacity to adjust shelf heights, widths, and even load capacities ensures the rack can accommodate diverse products, from thin aluminum sheets to thick steel plates. This scalability means your storage solution can evolve alongside your business, preventing premature obsolescence and providing a truly long-term asset.

Finally, a clear-eyed analysis of Cost-Effectiveness is required. While the initial investment for a robust, customizable system like the Herochu Horizontal Sheet Steel Storage Rack—starting at $3,660—may be higher than rudimentary alternatives, the long-term return on investment is substantial. This value is realized through lower labor costs, reduced material damage, improved safety, and enhanced operational throughput. Furthermore, selecting a system that is CE, EU, and ISO 9001 certified, as all Herochu products are, provides assurance of quality and durability, minimizing future maintenance expenses and ensuring compliance with international standards. By carefully weighing these five factors, you can make a confident decision that optimizes your workspace, protects your assets, and strengthens your operational foundation.

Q1: What steps should I take to start the procurement process?

Q2: How can I inform you of my need for suitable shelves?

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

Q4: Do you offer on-site installation and debugging services?

Q5: What measures do you take to ensure product quality?

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Q7: How can I verify your company’s strength?

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

PRODUCTS

-

Sheet Metal Storage Racks

Heavy Duty Sheet Metal Storage Racks of Warehouse

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Choose the Right Sheet Racking Systems & Storage Racks

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Choosing the Right Sheet Steel Storage Rack for Maximum Space Efficiency & Organization

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Fully automatic loading and unloading system for Laser Cutting Machines

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Automatic Loading and Unloading Systems of Laser Cutter

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Flexible Solution for Laser Cutter’s Loading and Unloading System

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Loading and Unloading Systems of Laser Cutting Process

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Industrial Shelving Systems for Heavy-Duty Sheet Metal Storage

Read moreRated 0 out of 5