Fully automatic loading and unloading system for Laser Cutting Machines

The Herochu Fully Automatic Loading and Unloading System for Laser Cutting Machines is engineered specifically to dismantle this barrier. This integrated solution transforms a standalone laser cutter into a continuous, labor-light production unit, enabling a prolonged, uninterrupted manufacturing process. By automating the entire material flow, from storage to finished part, the system ensures that your laser machine spends the maximum possible time doing what it does best: cutting. This discussion will explore the sophisticated components of a fully automated system, detail its operational workflow, and analyze the tangible benefits that justify its position as a critical upgrade for forward-thinking fabrication workshops.

Achieving Uninterrupted Production: The Herochu Fully Automatic Loading and Unloading System for Laser Cutting Machines

In the competitive landscape of modern metal fabrication, the pursuit of efficiency is relentless. Laser cutting machines represent a significant investment, chosen for their speed, precision, and versatility. However, the true potential of this advanced technology is often constrained not by its cutting capabilities, but by the manual processes that surround it. The intervals required for loading raw materials and unloading finished parts and scrap constitute significant downtime, creating a production bottleneck that limits output and inflates operational costs. For facilities targeting high-volume production, this intermittent workflow is a substantial barrier to growth and profitability.

The Herochu Fully Automatic Loading and Unloading System for Laser Cutting Machines is engineered specifically to dismantle this barrier. This integrated solution transforms a standalone laser cutter into a continuous, labor-light production unit, enabling a prolonged, uninterrupted manufacturing process. By automating the entire material flow, from storage to finished part, the system ensures that your laser machine spends the maximum possible time doing what it does best: cutting. This discussion will explore the sophisticated components of a fully automated system, detail its operational workflow, and analyze the tangible benefits that justify its position as a critical upgrade for forward-thinking fabrication workshops.

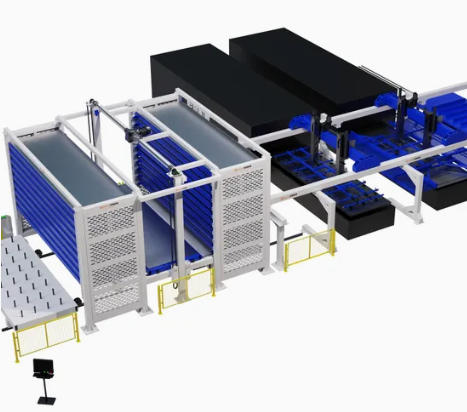

The Anatomy of a Fully Automated Production Cell

A Herochu system is not merely an accessory; it is a seamlessly integrated production ecosystem. The core configuration consists of a three-dimensional storage warehouse that acts as the raw material bank, a robust bilateral gantry truss for structural stability, and a highly precise loading and unloading composite truss manipulator that handles the material with absolute care. This is complemented by a finished material truck for part removal and a sophisticated PLC control system that acts as the central nervous unit, orchestrating every movement with flawless coordination. Together, these components form a sheet metal automatic production unit that effectively guarantees superior product quality, dramatically improves production efficiency, and systematically reduces long-term production costs.

The fundamental principle of a fully automatic system is the elimination of operator intervention during the core production cycle. Material is organized in stacks on pallets within the storage system. When the laser machine is ready for a new sheet, the automated material handling system, typically employing a powerful and intelligent vacuum lifter, retrieves a sheet from the pre-designated stack. An automated vehicle, such as a conveyor or shuttle cart, then transports the material to the cutting area. The sheet is presented to the cutting bed, where it is securely held in place by a clamping mechanism. The machine then automatically positions the material with micron-level accuracy, ensuring optimal orientation for the cutting program.

Once the laser cutting cycle is complete, the process reverses. The suction cups of the manipulator descend, lifting the entire skeleton containing the cut parts. This is swiftly moved away from the bed and placed onto a conveyor or a dedicated stacking area for finished goods. Simultaneously, or immediately thereafter, the next raw sheet is loaded, creating a seamless loop. This cycle repeats autonomously for hours, or even an entire shift, requiring no human presence. The system may be configured with various technologies to suit specific spatial and production needs, including loading and unloading carts for simpler applications, high-density storage towers for space-constrained environments, or articulated robots for maximum flexibility in handling different part geometries.

Tangible Advantages of Full Automation

The decision to integrate a fully automatic loading and unloading system is driven by a compelling return on investment calculated through multiple channels.

The most immediate benefit is a drastic reduction in labor costs. By automating the physically demanding and repetitive tasks of loading and unloading, a single operator can supervise multiple laser cells. This reallocates human resources to more value-added roles such as programming, quality control, and maintenance, thereby optimizing the workforce.

Productivity experiences a monumental surge. The system eradicates the downtime inherent in manual material changeover. Because loading and unloading occur automatically and with exceptional speed, the laser machine can operate continuously. This capability for a long period of laborless production, including lights-out operation, directly translates to a substantial increase in production volume and a superior return on the capital invested in the laser equipment itself.

Consistency and quality are also significantly enhanced. Manual positioning is susceptible to slight variations, which can affect cut quality and nesting efficiency. The automated system positions every sheet with identical precision, eliminating human error and ensuring that every batch meets the same high standard. This repeatability minimizes material waste and guarantees part accuracy.

Furthermore, operational safety is profoundly improved. Automating the handling of heavy, sharp-edged sheet metal removes personnel from the most hazardous aspects of the cutting process. The risk of musculoskeletal injuries from lifting or accidents involving the laser machine during manual intervention is effectively mitigated, fostering a safer working environment.

Considerations for Implementation

While the advantages are clear, a fully automatic system represents a strategic investment best suited for specific operational profiles. Small-scale workshops with lower-volume production may find the initial investment challenging to justify against their current output. The system does require a dedicated footprint for the storage warehouse and manipulator, necessitating a review of available floor space. Additionally, certain systems are engineered for specific material size ranges or thicknesses, so compatibility with a workshop’s primary materials must be confirmed during the planning stage.

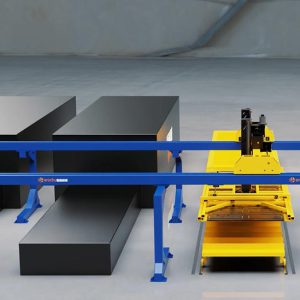

Advanced Configurations: Shuttle Tables and Pallet Changers

For operations requiring the utmost in continuous throughput, the shuttle table system presents an elegant solution. This configuration utilizes two or three tables that rotate in an endless loop. While one table is inside the laser machine being cut, another is outside being unloaded of finished parts and loaded with a new raw sheet. This rotation creates a truly non-stop production cycle, as there is zero waiting time for table exchange. These shuttle systems can be seamlessly combined with automatic storage and retrieval systems for a complete hands-off workflow.

Alternatively, the pallet changer system offers high efficiency for batch production. This system uses pallets that hold the raw material. Once the material on one pallet is cut, the entire pallet is automatically swapped with a new, pre-loaded pallet. This allows for very rapid changeover between different jobs or material types, minimizing non-productive time and enhancing flexibility within an automated framework.

Selecting the Optimal System for Your Workshop

The choice between a standard truss-based system, a shuttle table, or a pallet changer is not one-size-fits-all. It depends critically on factors unique to your operation. The type of material processed is paramount; a vacuum-based system is ideal for standard sheet metal, while specialized handlers may be needed for tubes or delicate materials. The desired production rate, the variety of part sizes, and the available floor space are all critical determinants.

Herochu systems are engineered with this need for customization at their core. Fully customizable to your workshop and production requirements, we ensure a perfect fit for your operational goals. Our commitment to quality and safety is validated by CE, EU, and ISO 9001 certification, providing assurance of international standards compliance.

Embrace the future of unmanned fabrication. The Herochu Fully Automatic Loading and Unloading System, starting at $12,288, is your gateway to unparalleled productivity, reduced operational costs, and a significant competitive advantage. Contact our engineering team today for a detailed consultation to explore how we can design a solution that perfectly aligns with your production ambitions.

Q1: What steps should I take to start the procurement process?

Q2: How can I inform you of my need for suitable shelves?

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

Q4: Do you offer on-site installation and debugging services?

Q5: What measures do you take to ensure product quality?

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Q7: How can I verify your company’s strength?

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

PRODUCTS

-

Sheet Metal Storage Racks

Heavy Duty Sheet Metal Storage Racks of Warehouse

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Choose the Right Sheet Racking Systems & Storage Racks

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Choosing the Right Sheet Steel Storage Rack for Maximum Space Efficiency & Organization

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Fully automatic loading and unloading system for Laser Cutting Machines

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Automatic Loading and Unloading Systems of Laser Cutter

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Flexible Solution for Laser Cutter’s Loading and Unloading System

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Loading and Unloading Systems of Laser Cutting Process

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Industrial Shelving Systems for Heavy-Duty Sheet Metal Storage

Read moreRated 0 out of 5