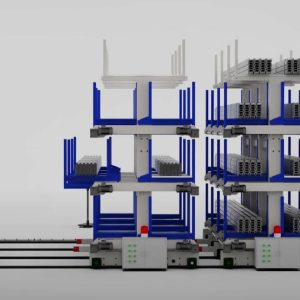

Heavy-Duty Cantilever warehouse racks

The Herochu Heavy-Duty Cantilever Rack system is engineered to eliminate these problems at their source. The design is elegantly robust, consisting of strong, certified steel upright columns with arms that project outwards, creating a series of vertical storage bays. This cantilevered arm design is the key to its versatility, as it provides unobstructed access from the front and sides, making it ideal for items that are long, bulky, or irregular in shape. There are no front-facing vertical posts to impede the loading and unloading process, which can be efficiently handled by forklifts or overhead cranes.

Reclaim Your Cubic Footprint: The Strategic Advantage of Herochu Heavy-Duty Cantilever Warehouse Racks

There is a pervasive and costly illusion in many industrial warehouses and workshops today. On the surface, the facility appears operational, even busy. Yet, a closer examination reveals a silent drain on profitability stretching from the floor to the ceiling. This drain is the vast volume of unused airspace above storage areas dedicated to long, cumbersome, or irregularly shaped materials. While the monthly rent or mortgage payment is calculated based on the entire cubic volume of the building, operational storage often neglects everything above the first ten or fifteen feet. The result is a significant financial paradox: you are paying for a three-dimensional asset but utilizing it as a one-dimensional plane.

This inefficiency represents one of the most substantial hidden costs in industrial operations. Consider the mathematics of a typical scenario. A warehouse with 20,000 square feet and a 26-foot clear height offers a total of 520,000 cubic feet of potential storage volume. If long materials like steel tubing, lumber, or plastic piping are laid flat in stacks that only reach five feet high, the effective use of a 2,000-square-foot section drops to a mere 10,000 cubic feet. This leaves 42,000 cubic feet of empty, paid-for space directly above. At a conservative lease rate of $0.038 per cubic foot per month, that unused air costs the business over $19,000 annually for just one section. This is capital that could be reinvested in new equipment, workforce development, or directly to the bottom line.

The solution to this volumetric inefficiency is not to seek a larger building, but to intelligently maximize the one you already own. This requires a shift from passive stacking to active, vertical storage engineering. Herochu addresses this fundamental challenge with our range of Heavy-Duty Cantilever Warehouse Racks. These are not simply shelving units; they are engineered systems designed to transform wasted vertical space into highly accessible, secure, and organized storage capacity. Starting at a accessible investment of $3,660 for a customizable setup, this system offers a rapid return by unlocking the latent potential of your existing facility.

The limitations of traditional storage methods for long items are numerous and impactful. Piling materials on the floor or on low-rise racks creates a host of operational and safety issues. Accessibility is poor, often requiring workers to move multiple heavy items to retrieve a specific piece from the bottom or middle of a stack. This process is not only time-consuming but also inherently dangerous, increasing the risk of musculoskeletal injuries from manual handling and creating instability that can lead to collapsing loads. Furthermore, this method subjects valuable inventory to damage through scratching, bending, and warping, directly impacting material quality and project costs.

The Herochu Heavy-Duty Cantilever Rack system is engineered to eliminate these problems at their source. The design is elegantly robust, consisting of strong, certified steel upright columns with arms that project outwards, creating a series of vertical storage bays. This cantilevered arm design is the key to its versatility, as it provides unobstructed access from the front and sides, making it ideal for items that are long, bulky, or irregular in shape. There are no front-facing vertical posts to impede the loading and unloading process, which can be efficiently handled by forklifts or overhead cranes.

Safety is an intrinsic feature of the Herochu cantilever system, not an afterthought. Each rack is designed, calculated, and manufactured to meet rigorous CE, EU, and ISO 9001 standards. This certification provides the assurance that the structure can safely support the specified load capacities, which are substantial. By providing a dedicated, secure location for each item, the system eliminates the unpredictable hazards of unsecured piles. The risk of items shifting, rolling, or collapsing is virtually eradicated. This creates a safer working environment, reduces the potential for costly accidents and product damage, and fosters a more organized, professional workspace.

A core principle of the Herochu philosophy is that every operation has unique requirements. Therefore, our Heavy-Duty Cantilever Warehouse Racks are not off-the-shelf products but customizable solutions. The system’s modularity allows it to be tailored precisely to your spatial constraints and material handling needs. Critical parameters such as the overall height of the uprights, the length and gauge of the cantilever arms, the number of vertical layers, and the spacing between arms can all be configured to optimize storage for your specific inventory. Whether you need to store short lengths of bar stock or 40-foot structural steel beams, the system can be engineered to provide the most efficient and safe solution.

The operational benefits of implementing this system are immediate and multifaceted. The most obvious is the dramatic increase in storage density. By stacking materials vertically, often to within a few feet of the ceiling, you actively utilize the cubic volume of your facility, potentially multiplying your effective storage capacity within the same footprint. This directly addresses the costly issue of wasted airspace. Secondly, efficiency sees a marked improvement. Forklift operators can store and retrieve items directly without the need for time-consuming rearrangement of other materials. This streamlines workflow, reduces labor time per task, and accelerates order fulfillment.

For businesses involved in warehousing, metal fabrication, construction supply, lumber distribution, or any industry that handles long goods, the Herochu Heavy-Duty Cantilever Rack is more than a storage product—it is a strategic tool for enhancing operational and financial performance. It represents a commitment to intelligent space utilization, workplace safety, and inventory integrity.

Before considering the significant capital expenditure of expanding your facility, first assess the potential lying dormant above your current operations. Partner with Herochu to conduct a professional evaluation of your storage challenges. Our experts can help you design a cantilever rack system that turns your costly empty air into your most valuable asset. Contact us today to explore how our certified, customizable Heavy-Duty Cantilever Warehouse Racks can deliver a measurable return on investment by reclaiming your cubic footprint.

Q1: What steps should I take to start the procurement process?

Q2: How can I inform you of my need for suitable shelves?

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

Q4: Do you offer on-site installation and debugging services?

Q5: What measures do you take to ensure product quality?

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Q7: How can I verify your company’s strength?

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

PRODUCTS

-

Heavy Duty Cantilever Racking System

Estanterias cantilever | Scaffalature cantilever

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Prateleira cantilever racking supplier

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Heavy-Duty Cantilever warehouse racks

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Long Goods Heavy Duty Cantilever Rack

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

New & Used Cantilever Racks | Heavy-Duty Storage Systems

Read moreRated 0 out of 5