Horizontal sheet storage Rack

Herochu is a trusted expert in material handling racking systems, with a focus on uncompromising safety, reliability, and performance. Our horizontal sheet storage racks are not just storage solutions—they’re investments in operational efficiency. Designed to complement laser cutting machines, shears, press brakes, and other production machinery, these racks keep your materials organized, accessible, and protected, reducing downtime and material damage during handling.

Category Sheet Metal Storage Racks

Tag Horizontal sheet storage Rack

Herochu Horizontal Sheet Storage Rack: Customizable, Certified, and Built for Industrial Efficiency

In busy workshops, factories, and manufacturing facilities, disorganized sheet metal, steel plates, aluminum sheets, and flat products waste valuable time, occupy excess floor space, and create safety hazards. Herochu’s Horizontal Sheet Storage Rack solves these challenges head-on—offering heavy-duty construction, customizable designs, and industry-leading certifications to streamline your material handling and inventory management. Starting at $5,199, our racks are engineered to meet the unique needs of your workshop, whether you’re storing small batches of specialty plates or high-volume industrial materials.

Why Choose Herochu’s Horizontal Sheet Storage Rack?

Herochu is a trusted expert in material handling racking systems, with a focus on uncompromising safety, reliability, and performance. Our horizontal sheet storage racks are not just storage solutions—they’re investments in operational efficiency. Designed to complement laser cutting machines, shears, press brakes, and other production machinery, these racks keep your materials organized, accessible, and protected, reducing downtime and material damage during handling.

Every Herochu horizontal sheet storage rack is fully CE, UE, and ISO 9001 certified, ensuring compliance with global quality and safety standards. For Australian clients, our racks also meet required local industry standards—built to withstand the harshest industrial environments, from heavy daily use to extreme temperature fluctuations. We don’t just build racks; we build solutions that you can rely on to perform consistently, even in the most demanding situations.

Standard Models: Designed for Versatility

Herochu offers four standard horizontal sheet storage rack models, each tailored to different plate sizes, load capacities, and workshop layouts. Each model follows a clear naming convention: “HC” for Herochu Constant Storage, “B” for Board Type, followed by dimensions (in meters) and key specs. Below is a detailed breakdown of our standard offerings:

1. HC-B3015-63

- Plate Size: 3000mm x 1500mm (3m x 1.5m)

- Single Layer Load Capacity: 3 tons

- Number of Layers: 5+1 (5 storage layers + 1 top access layer)

- Partition Layer Available Height: ≤220mm

- External Dimensions (L x H x W): 3505mm x 2280mm x 2000mm

- Door Open Width: 3515mm

- Bottom Layer Ground Clearance: 355mm

- Top Floor Height: 2195mm

- Depth Pad Height: 60mm

2. HC-B4015-63

- Plate Size: 4000mm x 1500mm (4m x 1.5m)

- Single Layer Load Capacity: 3 tons

- Number of Layers: 5+1

- Partition Layer Available Height: ≤220mm

- External Dimensions (L x H x W): 4505mm x 2280mm x 2000mm

- Door Open Width: 4015mm

- Bottom Layer Ground Clearance: 355mm

- Top Floor Height: 2195mm

- Depth Pad Height: 60mm

3. HC-B4020-65

- Plate Size: 4000mm x 2000mm (4m x 2m)

- Single Layer Load Capacity: 5 tons

- Number of Layers: 5+1

- Partition Layer Available Height: ≤220mm

- External Dimensions (L x H x W): 4505mm x 2280mm x 2500mm

- Door Open Width: 4015mm

- Bottom Layer Ground Clearance: 355mm

- Top Floor Height: 2250mm

- Depth Pad Height: 60mm

4. HC-B6020-66

- Plate Size: 6000mm x 2000mm (6m x 2m)

- Single Layer Load Capacity: 6 tons

- Number of Layers: 5+1

- Partition Layer Available Height: ≤220mm

- External Dimensions (L x H x W): 6505mm x 2280mm x 2500mm

- Door Open Width: 4015mm

- Bottom Layer Ground Clearance: 355mm

- Top Floor Height: 2250mm

- Depth Pad Height: 60mm

All standard models feature an integrated pull-out drawer movement method—allowing each drawer to extend completely for easy access to materials. This design eliminates the need for heavy lifting or awkward maneuvering, making it simple for one person to operate the rack using common workshop tools like lifters, vacuums, magnets, or hoists. Each drawer also includes a lock-in/lock-out mechanism, ensuring safe operation by preventing accidental movement while loading or unloading materials.

Fully Customizable to Your Workshop

No two workshops are the same—and Herochu understands that off-the-shelf solutions don’t always fit. If our standard models don’t match your specific plate sizes, load requirements, or space constraints, we offer fully customized horizontal sheet storage racks. Our team of engineers will work with you to design a rack that aligns with your exact specifications:

- Custom Plate Sizes: Whether you need to store smaller 1500mm x 1000mm plates or oversized 8000mm x 3000mm sheets, we’ll adjust the rack’s dimensions to fit.

- Adjustable Load Capacities: From 2 tons to 10 tons per layer, we’ll engineer the rack to support your material weight requirements.

- Tailored Layer Counts: Need more than 5+1 layers? We can increase or decrease the number of storage layers to maximize vertical space.

- Workshop-Specific Dimensions: If your facility has limited width, height, or floor space, we’ll design the rack to fit without compromising functionality.

Our customization process starts with a detailed consultation to understand your workflow, inventory, and space. We then create 3D models and engineering drawings for your approval before manufacturing—ensuring the final product integrates seamlessly into your operations.

Key Features That Drive Efficiency and Safety

Herochu’s horizontal sheet storage racks are built with the needs of industrial teams in mind. Here’s how they enhance your workshop:

- Maximize Vertical Space: By utilizing vertical storage, our racks reduce floor space usage by up to 50%, freeing up area for production machinery or additional workflow space.

- Streamline Inventory Management: Organize materials by size, type, or material (e.g., steel, aluminum, copper) for quick identification and retrieval—cutting down on time spent searching for materials.

- Heavy-Duty Durability: With a maximum single-layer load capacity of 6 tons (standard) and up to 10 tons (custom), our racks handle even the heaviest industrial sheets without bending or warping.

- Safe, Single-Person Operation: The integrated pull-out drawers and lock-in/lock-out mechanisms let one team member safely load/unload materials, reducing labor costs and minimizing injury risks.

- Reduce Material Damage: By keeping sheets secure and separated, our racks prevent scratches, dents, and bending—protecting your valuable inventory and reducing waste.

- Seamless Production Integration: Designed to work alongside laser cutters, press brakes, and shears, our racks keep materials close to production lines, reducing material transport time and improving workflow.

More Than Just Racks: Herochu’s Material Handling Expertise

Herochu doesn’t just sell horizontal sheet storage racks—we offer a full range of material handling solutions to fit every industrial workspace. From free-standing vertical sheet storage racks to custom-engineered racking systems, we have the expertise to solve your storage challenges. If we don’t stock a solution that meets your needs, our in-house engineering team will design and build one from scratch—ensuring it aligns with your workflow, safety requirements, and budget.

Our commitment to safety and professionalism sets us apart. Every rack we design is tested to withstand the rigors of industrial use, and our team works closely with you to ensure proper installation and training. We pride ourselves on our safety-first approach, knowing that a secure workplace is a productive workplace.

Invest in Herochu’s Horizontal Sheet Storage Rack Today

If you’re tired of disorganized materials, wasted space, and inefficient workflows, Herochu’s Horizontal Sheet Storage Rack is the solution you need. Starting at $5,199, our certified, customizable racks are built to last—and designed to help your workshop run smoother, safer, and more efficiently. Whether you choose a standard model or a custom design, you’ll get a product that meets global quality standards and aligns with your unique needs.

Contact Herochu today to discuss your workshop’s storage requirements. Our team will help you select the right rack, provide a detailed quote, and guide you through every step of the process—from design to installation. Experience the Herochu difference: reliable, safe, and tailored material handling solutions that grow with your business.

Q1: What steps should I take to start the procurement process?

You may get in touch with our backend technical staff first. Based on your specific parameters, we will formulate a suitable technical solution and provide a quotation. Alternatively, you can leave your contact details—such as WhatsApp, WeChat, or email address—and our professional sales team will reach out to you proactively.

Q2: How can I inform you of my need for suitable shelves?

You can share key information with us, including the type of items you plan to store on the shelves, the dimensions of those items, the quantity of shelves required, and any other specific details you have. With this information, we will develop a professional solution tailored to your needs. If you prefer, you can also leave your contact information, and our specialized team will contact you to address your questions.

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

To determine the right option, two key factors need to be considered first:

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

For a more accurate recommendation based on your specific needs, please leave your contact information, and we will provide targeted service.

Q4: Do you offer on-site installation and debugging services?

Yes, we do. We can dispatch professional technicians to your factory to carry out on-site installation and debugging of the robotic arm, and we will continue working until the equipment completes a successful trial operation. Our team has provided such services in many countries, including South Africa, the United States, Russia, South Korea, Qatar, Egypt, Lebanon, and Mexico.

Q5: What measures do you take to ensure product quality?

We have a comprehensive quality assurance system, supported by the following key measures:

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Our factory is located in Jinan, Shandong Province, China, specifically at No. 10 Industrial Park, Jiyang Street. It features a modern, standard workshop covering an area of 10,000 square meters.

Q7: How can I verify your company’s strength?

We offer two convenient ways for you to assess our company’s capabilities:

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

We are Jinan Constant Storage Machinery Manufacturing Co., Ltd., a high-tech enterprise that integrates research and development, production, sales, installation, and after-sales service. Our core product range includes intelligent sheet metal material warehouses, drawer-type sheet metal shelves, telescopic cantilever shelves, servo swing arm manipulators, gantry loading and unloading manipulators, fully automatic loading and unloading systems, and heavy-duty sheet metal and pipe storage shelves. Equipped with a professional technical team and advanced production equipment, we are committed to providing high-quality, high-performance mechanical products and customized solutions to customers around the world.

PRODUCTS

-

Fiber Laser Automation Systems

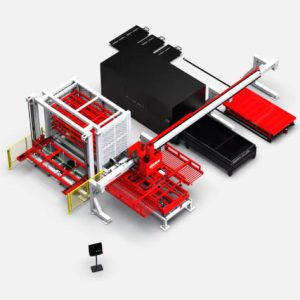

Automation loading and unloading systems for Laser Processing Machines

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Fiber Laser Automation | Automatic Loading And Unloading

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Loading & Unloading Equipment Servo swing arm handling manipulator

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Advanced Sheet Metal Palletizing Robot for Efficient Automation Solutions

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Heavy Duty Roll Out Cantilever Pipe Storage Racks

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Laser Loading and Unloading Systems Suction Crane Vacuum Lifter for Sheet Metal

Read moreRated 0 out of 5