Industrial Shelving Systems for Heavy-Duty Sheet Metal Storage

The Warehouse Space Revolution: How Herochu’s Honeycomb Rack Solves Your Storage Challenges

Introduction: The Hidden Cost of Inefficient Storage

For years, warehouse managers have struggled with the same frustrating dilemma: “We have enough square footage, but nowhere to store materials.” This was the exact problem faced by a Dallas-based manufacturer who, after investing in Herochu’s Roll Out Honeycomb Rack, reclaimed 45% of wasted space without expanding their facility.

The Warehouse Space Revolution: How Herochu’s Honeycomb Rack Solves Your Storage Challenges

Introduction: The Hidden Cost of Inefficient Storage

For years, warehouse managers have struggled with the same frustrating dilemma: “We have enough square footage, but nowhere to store materials.” This was the exact problem faced by a Dallas-based manufacturer who, after investing in Herochu’s Roll Out Honeycomb Rack, reclaimed 45% of wasted space without expanding their facility.

Why Traditional Cantilever Racks Fall Short

- Dead Space: Arms and gaps prevent tight stacking, wasting vertical and horizontal space.

- Inflexibility: Fixed configurations limit adaptability to changing inventory needs.

- Operational Inefficiency: Wide aisles reduce storage density and slow material handling.

Herochu’s Solution: The Honeycomb Storage Advantage

1. Unmatched Space Efficiency

- Compact Footprint: 21ft L x 10.5ft W x 12ft H vs. 33ft L x 10ft W x 7ft H for cantilever racks.

- 2.6x Capacity: Stores 250 pipes in the same space previously held 100.

- Sliding Cartridges: Tight 2ft x 2ft slots with pull-out access, eliminating wide aisles.

2. Engineered for Heavy-Duty Use

- 10,000 lb Capacity: Supports steel pipes, lumber, and long-form materials.

- CE, EU, ISO 9001 Certified: Meets global safety and quality standards.

- Customizable: Starting at $5,680, tailored to your workshop dimensions.

3. Operational Benefits

- Faster Retrieval: Sliding units reduce forklift travel time.

- Improved Safety: Eliminates overhanging hazards and cluttered aisles.

- Weatherproofing: Optional roofing protects materials from rain/snow.

Real-World Results: A Case Study

A Texas manufacturer transformed their 2,000 sq. ft warehouse:

- Before: 100 pipes stored with cantilever racks, wasted vertical space.

- After: 250 pipes stored in the same footprint, with clear aisles and streamlined workflows.

Frequently Asked Questions

Q: Can this system integrate with existing racks?

A: Yes, Herochu designs hybrid solutions to maximize legacy equipment.

Q: What’s the lead time for customization?

A: Standard units ship in 2-4 weeks; custom orders require consultation.

Q: Is installation complex?

A: Modular assembly takes 4-6 hours with minimal tools.

Conclusion: Stop Leaking Space, Start Maximizing It

Herochu’s Honeycomb Rack isn’t just storage—it’s a space reclamation system. Whether you handle pipes, sheet metal, or lumber, our design ensures your warehouse works harder, not bigger.

Ready to Optimize Your Space?

Contact Herochu today for a free facility assessment and discover how we can turn your storage challenges into efficiency gains.

Q1: What steps should I take to start the procurement process?

Q2: How can I inform you of my need for suitable shelves?

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

Q4: Do you offer on-site installation and debugging services?

Q5: What measures do you take to ensure product quality?

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Q7: How can I verify your company’s strength?

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

PRODUCTS

-

Fiber Laser Automation Systems

Fully automatic loading and unloading system for Laser Cutting Machines

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Automatic Loading and Unloading Systems of Laser Cutter

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Flexible Solution for Laser Cutter’s Loading and Unloading System

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Loading and Unloading Systems of Laser Cutting Process

Read moreRated 0 out of 5 -

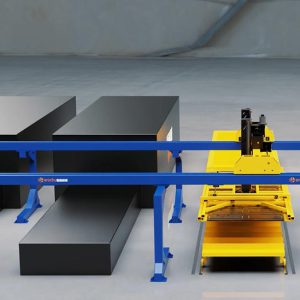

Sheet Metal Storage Racks

Industrial Shelving Systems for Heavy-Duty Sheet Metal Storage

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Efficient Heavy Duty Horizontal Sheet Metal Storage Rack System

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Automatic warehouses for sheet metal storage

Read moreRated 0 out of 5