Intelligent Sheet Metal Storage System

Sheet metal fabrication demands precision at every step, and storage is no exception. Whether you’re working with thin aluminum sheets for electronics enclosures or thick steel plates for construction, mismanagement leads to delays, waste, and accidents. Herochu’s Intelligent Sheet Metal Storage System addresses these pain points head-on, combining robust engineering with smart controls to solve the problems fabricators face daily. From leftover sheet tracking to seamless machine integration, this system is built to work as hard as your team does.

Herochu Intelligent Sheet Metal Storage System: Streamline, Secure, and Customize Your Fabrication Workflow

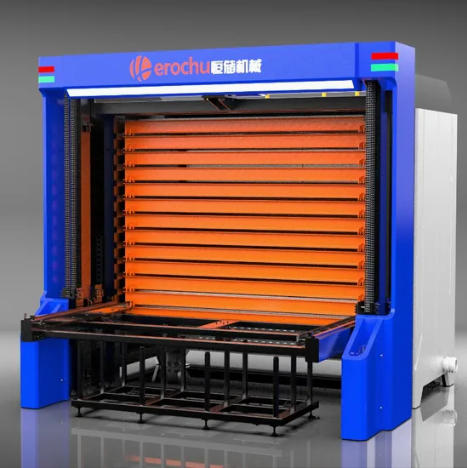

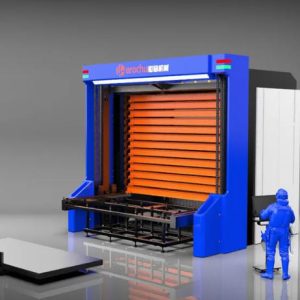

In the fast-paced world of sheet metal fabrication, inefficiency doesn’t just slow down production—it eats into profits. Manual storage methods force teams to waste hours hunting for materials, risk damage to valuable sheets, and create unsafe work environments with constant forklift and crane movements. Herochu’s Intelligent Sheet Metal Storage System changes this narrative. More than just a storage solution, it’s a fully integrated, certified tool designed to centralize inventory, automate workflows, and adapt to your workshop’s unique needs—all starting at $19,998. Backed by CE, UE, and ISO 9001 certifications, this system turns disorganized storage into a competitive edge, making your operations safer, faster, and more profitable.

Why Herochu’s Intelligent Sheet Metal Storage System? A Solution Built for Real Fabrication Challenges

Sheet metal fabrication demands precision at every step, and storage is no exception. Whether you’re working with thin aluminum sheets for electronics enclosures or thick steel plates for construction, mismanagement leads to delays, waste, and accidents. Herochu’s Intelligent Sheet Metal Storage System addresses these pain points head-on, combining robust engineering with smart controls to solve the problems fabricators face daily. From leftover sheet tracking to seamless machine integration, this system is built to work as hard as your team does.

1. Unmatched Durability: Engineered for Industrial Rigor

Every component of Herochu’s Intelligent Sheet Metal Storage System is crafted to withstand the demands of daily fabrication. The system’s core structure—from the frame to the storage units—is made from high-grade steel, selected for its exceptional strength, corrosion resistance, and long-term reliability. With a per-layer load capacity of 3T or 5T, it handles even the heaviest materials, from thick 6025mm steel plates to dense copper sheets, without bending or compromising structural integrity.

The system’s movement relies on a linear guide rail + chain design, a combination that ensures smooth, consistent operation even under full load. Unlike flimsy roller systems that jam or wear out quickly, Herochu’s linear guides reduce friction, cutting down on maintenance needs and extending the system’s lifespan. The chain drive transmission adds another layer of dependability: it delivers steady power to move storage units, ensuring precise positioning every time—no slipping, no misalignment, and no costly downtime.

Before any system leaves our factory, it undergoes rigorous testing to meet global safety and quality standards, earning CE, UE, and ISO 9001 certifications. This isn’t just a storage unit; it’s a long-term investment in your workshop’s efficiency and safety.

2. Customization That Fits Your Workshop Like a Glove

No two fabrication shops are the same. A small HVAC business might need a compact system for 3015mm galvanized sheets, while a large automotive supplier requires a multi-unit setup for 6025mm steel plates. Herochu’s Intelligent Sheet Metal Storage System is fully customizable to match your space, materials, and production volume, starting with core specifications that adapt to your needs:

- Sheet Size Compatibility: Supports standard sizes from 3015mm (ideal for small parts) up to 6025mm (for large-scale projects), including 4015mm, 4020mm, and 6015mm—covering nearly every common sheet metal dimension.

- Number of Floors: Tailored to your vertical space. Whether you need 5 layers to save floor space or 15 layers to maximize storage capacity, we design a system that uses height efficiently without sacrificing safety.

- Number of Storage Units: Adjusted to your inventory volume. A single unit works for small batches, while multi-unit setups handle high-volume production—each unit synced to work with your other equipment.

- Plate Support: Optional configurations to protect delicate or irregular sheets. Choose rubberized supports for scratch-sensitive aluminum, reinforced steel supports for heavy plates, or custom designs for specialty materials.

Our customization process goes beyond specs. We start with a detailed consultation: our team visits your workshop to measure space, assess your material types (steel, aluminum, copper), and map your production flow (e.g., laser cutting → punching → bending). We then design a system that fits around existing machinery, connects to your MES (Manufacturing Execution System), and aligns with your daily output goals. The result? A storage system that feels like it was built for your shop—because it was.

3. Efficient Leftover Sheet Management: Stop Wasting Valuable Materials

One of the biggest hidden costs in fabrication is leftover sheet metal. After cutting or punching, useful remnants often end up scattered across the shop floor—hard to track, easy to lose, and rarely reused. Herochu’s Intelligent Sheet Metal Storage System solves this with a dedicated leftover sheet management feature.

The system lets you easily register leftover sheets via its PLC and touch screen interface, assigning each a unique location and digital label. No more digging through piles of scraps or guessing if a leftover sheet is the right size—simply search the system, and it will direct you to the exact storage unit. This keeps your workshop organized, reduces material waste, and turns leftover sheets into usable inventory. For example, a shop that processes 50 sheets a day might save hundreds of dollars monthly by reusing leftovers instead of buying new material.

4. Seamless Integration: Connect to Your Existing Workflow

Herochu’s Intelligent Sheet Metal Storage System isn’t a standalone tool—it’s designed to fit seamlessly into your existing fabrication workflow. It easily links to conveyor systems, streamlining the movement of sheets between storage and production. Whether you’re moving raw materials to a laser cutting machine or finished parts to shipping, the system eliminates manual handling, cutting down on logistics time.

It also connects effortlessly to key fabrication equipment, including:

- Laser cutting machines

- Shear center lines

- Robotic press brakes

- Automatic punching centers

This integration creates a smooth, continuous workflow: the system receives a signal from your machine (or MES) requesting a specific sheet, automatically retrieves it using its 12m/min inlet/outlet speed, and delivers it directly to the machine. After processing, finished parts or leftovers are automatically returned to storage. No more waiting for forklifts or manual transport—your production line keeps moving, and your team stays focused on skilled work.

5. Enhanced Safety: Fewer Movements, Fewer Risks

Traditional sheet metal storage relies heavily on forklifts and cranes, creating constant movement in the workshop. This isn’t just time-consuming—it’s risky. Every lift or transport increases the chance of accidents (e.g., collisions, dropped sheets) and material damage. Herochu’s Intelligent Sheet Metal Storage System drastically reduces these risks by minimizing forklift and crane movements.

The system’s automated retrieval and delivery eliminate the need for manual machine operation for most tasks. Sheets are moved directly from storage to machines (and back) via the system’s linear guide rails and chain drive, with built-in safety features like emergency stop buttons, overload protection, and anti-collision sensors. This creates a safer working environment: fewer accidents, less material damage, and a more focused team. For shops prioritizing worker safety, this feature alone makes the system a game-changer.

6. Smart Automation: PLC Control for Effortless Management

At the heart of Herochu’s Intelligent Sheet Metal Storage System is a user-friendly PLC (Programmable Logic Controller) and touch screen interface. This lets you manage every aspect of storage with minimal effort:

- Centralized Storage: The system centralizes all sheets in one location, eliminating scattered piles and manual shelving. Load sheets once, and the system automatically indexes them, assigning each to a dedicated unit.

- Automatic Weight Detection: Built-in sensors weigh each sheet as it’s loaded, logging data into the PLC. This ensures accurate inventory tracking (no more guessing how many sheets are left) and prevents overloading—protecting both the system and your materials.

- Classified Visual Management: Every storage unit is labeled digitally (and physically, if needed) with sheet details—material type, thickness, size, and location. The touch screen displays a real-time map of all inventory, so you can find any sheet in seconds. No more digging through stacks or searching for misplaced labels—visibility is complete, and errors are minimized.

Workers don’t need specialized training to operate the system. The touch screen uses clear icons for “retrieve,” “store,” “inventory check,” and “leftover registration,” so even new team members can learn to use it in less than an hour.

7. Fast, Reliable Performance: Keep Production Moving

Herochu’s Intelligent Sheet Metal Storage System is built for speed, with features that keep your workflow efficient:

- Vertical Lifting Speed: 9m/min, ensuring quick access to even the topmost layers. Whether you’re retrieving a sheet from the 2nd floor or the 15th, the system moves smoothly and precisely—no delays.

- Inlet/Outlet Speed: 12m/min, getting sheets to and from machines fast. For a shop that processes 100 sheets a day, this cuts retrieval time by up to 70% compared to manual methods—saving hours of labor weekly.

This speed translates to faster production cycles, shorter lead times, and happier customers. When your storage system keeps up with your machines, you can take on more orders and meet tight deadlines with ease.

What’s Included in Every Herochu Intelligent Sheet Metal Storage System?

Every system is a turnkey solution, with all components needed to get up and running quickly—no need to source parts from multiple vendors. Standard inclusions:

- Steel Storage Frame: Heavy-duty steel frame with customizable floor count, designed to support 3T/5T per layer.

- Linear Guide Rails + Chain Drive: Smooth-moving rails and durable chain transmission for reliable sheet transport.

- PLC Control System: Industrial-grade PLC with touch screen interface, pre-programmed for common operations (retrieval, storage, inventory tracking, leftover registration).

- Weight Sensors: Built-in sensors for automatic weight detection and inventory logging.

- Vertical Lifting Mechanism: High-speed lifting system (9m/min) for access to all layers.

- Sheet Support Units: Optional rubberized or steel supports, customizable to your material type.

- Safety Features: Emergency stop buttons, overload protection, and anti-collision sensors to ensure worker and material safety.

For customers integrating with production lines, we also include:

- MES Integration Software: To connect the system to your existing MES or ERP (Enterprise Resource Planning) software.

- Conveyor System Compatibility: Pre-wired connections to ensure seamless communication with your conveyor equipment.

Our Promise: Quality, Service, and Partnership

At Herochu, we stand behind our products. Every new development is extensively tested in our factory to ensure it meets the highest quality standards—our motto is simple: “we either do it right or we don’t do it.” We don’t just sell you a system; we work with you to create a tailor-made solution that fits your needs and business processes.

And our support doesn’t end after installation. Our own service team is always ready to help you quickly and competently—whether you need troubleshooting, maintenance, or software updates. This gives you the assurance that your storage system will always operate at its best.

Who Uses Herochu’s Intelligent Sheet Metal Storage System?

Our system is trusted by fabricators and manufacturers across industries:

- Automotive: Store steel and aluminum sheets for body panels, with seamless integration to robotic press brakes.

- Aerospace: Manage precision aluminum or titanium sheets, with leftover tracking to reduce waste.

- HVAC: Store 3015mm–4020mm galvanized steel sheets for ducts, with fast retrieval to keep up with high-volume orders.

- Construction: Handle large 6020mm–6025mm steel plates, with fewer forklift movements for safer operations.

- Electronics: Store thin-gauge copper or aluminum sheets for enclosures, with PLC tracking to avoid material mix-ups.

No matter your industry, if you work with sheet metal, Herochu’s system will streamline your workflow.

Invest in Efficiency: Starts at $19,998

Quality intelligent storage shouldn’t be out of reach. Herochu’s Intelligent Sheet Metal Storage System starts at $19,998 for a standard single-unit setup (3015mm size, 5 layers, 3T per layer)—an affordable entry point for small to mid-sized shops. Custom systems (multi-unit, larger sizes, 5T capacity) are priced based on your needs, but we always prioritize value: every feature is designed to deliver a return on investment.

Every system comes with a 2-year warranty (extendable to 5 years) and ongoing support from our team. Whether you need help troubleshooting, replacing a part, or updating the PLC software, we’re available 24/7.

Ready to Transform Your Fabrication Workflow?

Don’t let manual storage slow down your production, waste materials, or put your team at risk. Herochu’s Intelligent Sheet Metal Storage System—certified, customizable, and built for industrial use—turns sheet metal management into a strength. It’s not just about storing sheets; it’s about making your entire operation more efficient, safer, and more profitable.

Contact our team today to schedule a workshop consultation. We’ll walk you through the design process, show you how the system integrates with your existing equipment, and help you calculate your potential savings. Let’s build a storage solution that works as hard as your team does.

Herochu: Intelligent Storage for the Future of Fabrication.

Q1: What steps should I take to start the procurement process?

You may get in touch with our backend technical staff first. Based on your specific parameters, we will formulate a suitable technical solution and provide a quotation. Alternatively, you can leave your contact details—such as WhatsApp, WeChat, or email address—and our professional sales team will reach out to you proactively.

Q2: How can I inform you of my need for suitable shelves?

You can share key information with us, including the type of items you plan to store on the shelves, the dimensions of those items, the quantity of shelves required, and any other specific details you have. With this information, we will develop a professional solution tailored to your needs. If you prefer, you can also leave your contact information, and our specialized team will contact you to address your questions.

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

To determine the right option, two key factors need to be considered first:

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

For a more accurate recommendation based on your specific needs, please leave your contact information, and we will provide targeted service.

Q4: Do you offer on-site installation and debugging services?

Yes, we do. We can dispatch professional technicians to your factory to carry out on-site installation and debugging of the robotic arm, and we will continue working until the equipment completes a successful trial operation. Our team has provided such services in many countries, including South Africa, the United States, Russia, South Korea, Qatar, Egypt, Lebanon, and Mexico.

Q5: What measures do you take to ensure product quality?

We have a comprehensive quality assurance system, supported by the following key measures:

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Our factory is located in Jinan, Shandong Province, China, specifically at No. 10 Industrial Park, Jiyang Street. It features a modern, standard workshop covering an area of 10,000 square meters.

Q7: How can I verify your company’s strength?

We offer two convenient ways for you to assess our company’s capabilities:

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

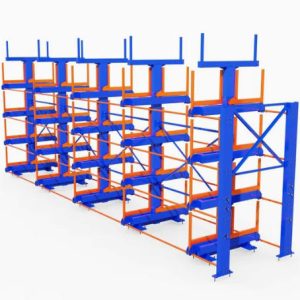

We are Jinan Constant Storage Machinery Manufacturing Co., Ltd., a high-tech enterprise that integrates research and development, production, sales, installation, and after-sales service. Our core product range includes intelligent sheet metal material warehouses, drawer-type sheet metal shelves, telescopic cantilever shelves, servo swing arm manipulators, gantry loading and unloading manipulators, fully automatic loading and unloading systems, and heavy-duty sheet metal and pipe storage shelves. Equipped with a professional technical team and advanced production equipment, we are committed to providing high-quality, high-performance mechanical products and customized solutions to customers around the world.

PRODUCTS

-

Heavy Duty Cantilever Racking System

Telescopic Cantilever Shelves Long Materials Storage

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Pipe Telescopic Cantilever Shelf Metal Sheet Warehouse Storage Rack

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Intelligent Sheet Metal Storage System

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Handling of plates and sheets, vacuum lifting

Read moreRated 0 out of 5 -

Sheet Metal Material Handling Equipment

Steel Sheet Metal Vacuum Lifting Device

Read moreRated 0 out of 5