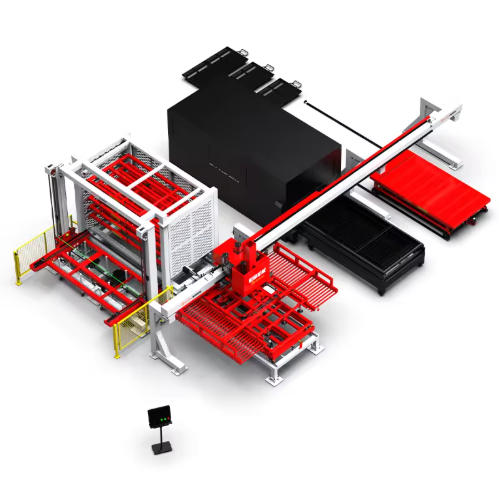

Loading and Unloading Systems of Laser Cutting Process

A loading and unloading system is the essential bridge between raw material storage and the finished component. The loading mechanism is responsible for the precise and reliable transfer of raw material—be it sheet metal, tubes, or profiles—from a storage unit into the laser cutting machine’s work area. Conversely, the unloading system efficiently removes the cut parts and the residual skeleton or scrap, sorting them into designated collection points. When these processes are manual, they are inherently slow, variable, and physically demanding. Automating these tasks ensures a consistent, predictable, and rapid cycle time, effectively allowing the laser cutter to operate at its full potential with minimal human intervention.

|

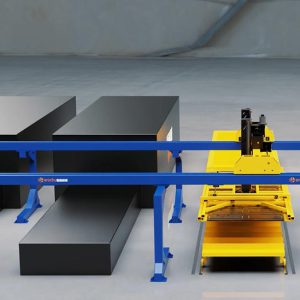

Specification

|

3015/4015/4020/6015/6020/6025mm

|

|

Number of floor

|

8-13

|

|

Load per layer

|

3T/5T

|

|

Mode of movement

|

Linear guide rail + chain

|

|

Transmission mode

|

Chain drive

|

|

Vertical lifting Speed

|

9m/min

|

|

Inlet and outlet Speed

|

12m/min

|

|

Plate Support

|

optional selection

|

Optimizing Material Flow: A Comprehensive Guide to Laser Cutting Loading and Unloading Systems by Herochu

Within the modern fabrication environment, the laser cutting machine stands as a paragon of efficiency, delivering unparalleled speed and precision. However, the true measure of a production cell’s productivity is not solely the cutting speed of the laser itself, but the holistic flow of materials into and out of the work envelope. The loading and unloading phases are critical junctures where significant time can be lost, creating bottlenecks that undermine the laser’s inherent capabilities. Manual material handling, once the standard, is increasingly viewed as obsolete, introducing unnecessary downtime, elevated labor costs, and heightened operational risks.

At Herochu, we engineer solutions that transform this critical part of your production chain. Our focus is on integrating robust, intelligent loading and unloading systems for laser cutting processes that synchronize perfectly with your equipment, unlocking unprecedented levels of automation, safety, and throughput. This article delves into the various types of loading and unloading systems, their respective advantages, and how a strategic investment can yield a rapid return by maximizing the uptime of your most valuable assets.

The Critical Role of Loading and Unloading in Laser Cutting

A loading and unloading system is the essential bridge between raw material storage and the finished component. The loading mechanism is responsible for the precise and reliable transfer of raw material—be it sheet metal, tubes, or profiles—from a storage unit into the laser cutting machine’s work area. Conversely, the unloading system efficiently removes the cut parts and the residual skeleton or scrap, sorting them into designated collection points. When these processes are manual, they are inherently slow, variable, and physically demanding. Automating these tasks ensures a consistent, predictable, and rapid cycle time, effectively allowing the laser cutter to operate at its full potential with minimal human intervention. This is not merely about replacing labor; it is about augmenting your workshop’s capabilities to achieve a seamless, continuous production rhythm.

An Analysis of Common Loading and Unloading System Configurations

Understanding the spectrum of available solutions is the first step toward optimization. The choice between manual, semi-automatic, and fully automated systems depends on production volume, material variety, floor space, and budgetary considerations.

1. Manual Loading and Unloading

The traditional approach involves an operator physically lifting and positioning each raw material sheet or tube onto the laser machine’s cutting bed. After the cycle is complete, the operator must then remove the finished parts and separate them from the scrap material manually.

-

Perceived Advantages:

-

Lower Initial Investment: The primary attraction of a manual system is the absence of a significant capital outlay for automation hardware.

-

Handling Flexibility: An experienced operator can adeptly handle irregular or delicate materials that might challenge a standardized automated system.

-

-

Significant Disadvantages:

-

High Labor Costs and Inefficiency: Requiring a dedicated operator for loading and unloading duties constitutes a continuous and substantial operational expense.

-

Production Bottlenecks: The machine remains idle during material changeover, leading to considerable downtime between jobs and severely limiting overall equipment effectiveness (OEE).

-

Inconsistency and Human Error: Manual positioning can lead to misalignment, potentially affecting cut quality and increasing material waste.

-

Workplace Safety Concerns: The repetitive handling of heavy, sharp-edged sheets poses significant ergonomic risks and potential for injury.

-

2. Semi-Automatic Loading and Unloading

This configuration represents a middle ground, blending automated components with targeted operator involvement. A typical semi-automatic system might feature an automated loading arm or a simple destacker that places the material onto the bed, but require an operator to initiate the process or handle the finished parts.

-

Advantages:

-

Enhanced Productivity: By automating the most physically demanding aspects of loading, cycle times are reduced compared to fully manual operations.

-

Reduced Labor Strain: Operators are freed from repetitive heavy lifting, improving workplace safety and morale.

-

Moderate Cost Increase: Semi-automatic systems offer a meaningful productivity boost at a more accessible price point than full automation.

-

-

Disadvantages:

-

Partial Dependence on Labor: The system does not eliminate the need for an operator’s presence, meaning labor costs and the potential for human error, though reduced, persist.

-

Not a Complete Solution: For facilities targeting lights-out manufacturing or 24/7 operation, a semi-automatic system remains a limiting factor.

-

The Herochu Advantage: Fully Integrated Automated Loading and Unloading Systems

While semi-automation offers an improvement, the pinnacle of laser cutting efficiency is achieved with a fully automated loading and unloading system. A Herochu system is engineered as a cohesive unit, comprising high-capacity material storage racks, intelligent destacking mechanisms, precision transfer cars, and automated sorting tables for finished parts and scrap. This integrated approach creates a closed-loop material handling environment.

The operational workflow is seamless. Raw sheets are automatically retrieved from the storage rack and positioned with micron-level accuracy on the laser bed. Upon completion of the cutting cycle, the system simultaneously unloads the finished skeleton while loading the next raw sheet, a process known as “shuttle” or “exchange” loading that eliminates machine idle time. Finished parts are then conveyed to a sorting station, where they can be automatically organized, while scrap is deposited into a dedicated container.

The tangible benefits of a Herochu automated system include:

-

Maximized Machine Uptime: By virtually eliminating non-cutting time, our systems ensure your laser investment is producing parts, not waiting for them.

-

Substantial Labor Cost Reduction: One operator can manage multiple laser cells, reallocating human expertise to higher-value tasks like quality control and programming.

-

Uncompromising Consistency and Quality: Automated precision ensures perfect material placement for every cycle, leading to optimal cut quality and reduced material waste.

-

Enhanced Operational Safety: Automating the handling of heavy and sharp materials significantly mitigates workplace injuries and creates a cleaner, more organized production floor.

-

Scalability for Future Growth: Herochu systems are designed to be modular, allowing for future expansion of storage capacity or integration with downstream processes like bending or welding.

Engineered for Your Workshop, Backed by Global Certification

We recognize that no two workshops are identical. Every Herochu Loading and Unloading System is customizable to your specific workshop layout, material specifications, and production goals. Our engineering team works directly with you to design a solution that integrates flawlessly with your existing laser machinery and spatial constraints. Furthermore, our commitment to quality and safety is unequivocal, with all systems being CE, EU, and ISO 9001 certified, guaranteeing compliance with the highest international standards for performance and workplace safety.

Invest in a system that empowers your production. The Herochu Loading and Unloading System is the definitive solution for fabricators seeking to eliminate bottlenecks, reduce costs, and achieve new levels of manufacturing excellence. Contact our technical specialists today for a confidential consultation and discover how our systems, starting at $12,288, can transform your laser cutting process.

Q1: What steps should I take to start the procurement process?

Q2: How can I inform you of my need for suitable shelves?

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

Q4: Do you offer on-site installation and debugging services?

Q5: What measures do you take to ensure product quality?

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Q7: How can I verify your company’s strength?

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

PRODUCTS

-

Fiber Laser Automation Systems

Fully automatic loading and unloading system for Laser Cutting Machines

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Automatic Loading and Unloading Systems of Laser Cutter

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Flexible Solution for Laser Cutter’s Loading and Unloading System

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Loading and Unloading Systems of Laser Cutting Process

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Industrial Shelving Systems for Heavy-Duty Sheet Metal Storage

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Efficient Heavy Duty Horizontal Sheet Metal Storage Rack System

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Automatic warehouses for sheet metal storage

Read moreRated 0 out of 5