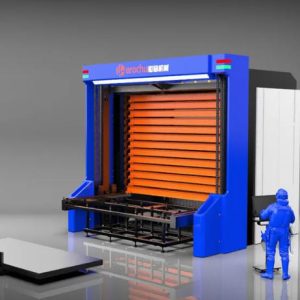

Loading/unloading System for Fiber Laser Cutting Machine

At the heart of the system is an independent vacuum loading and unloading unit. Unlike basic systems that rely on mechanical clamps (which can scratch or damage materials), the vacuum system uses controlled suction to lift and move sheets gently. This not only protects delicate surfaces but also ensures a secure grip on even irregularly shaped materials. The independent design means loading and unloading can happen simultaneously: while the system unloads a finished part from the laser cutter, it’s already fetching the next raw sheet from storage. This parallel workflow cuts cycle times by up to 40%, keeping your laser cutter operating at peak capacity.

Herochu Loading/unloading System for Fiber Laser Cutting Machine: Elevate Material Handling Efficiency

In the world of fiber laser cutting, where precision and speed define success, material handling often becomes the hidden bottleneck. Even the most advanced laser cutter can’t reach its full potential if operators are stuck manually loading heavy sheets, waiting to unload finished parts, or struggling to organize raw materials. These manual tasks waste time, increase labor costs, and introduce the risk of errors—from scratched sheets to misaligned loads that ruin cuts. Herochu’s Loading/unloading System for Fiber Laser Cutting Machine was built to eliminate these pain points. This integrated, customizable solution automates every step of material handling, turning disjointed workflows into seamless operations. Whether you’re running a small fabrication shop or a high-volume manufacturing facility, this system ensures your laser cutter stays productive—so you can focus on delivering quality parts, not managing materials.

Built for Industrial Versatility: Key Specifications

Herochu’s Loading/unloading System is engineered to work with the most common fiber laser cutting machine sizes, ensuring compatibility with your existing setup or new equipment. It offers six standard working area configurations to match your production needs: 3015mm, 4015mm, 4020mm, 6015mm, 6020mm, and 6025mm. This range covers everything from small-batch precision parts (e.g., 3015mm for electronics components) to large-format sheets (e.g., 6025mm for automotive body panels or construction metalwork). No matter the size of your laser cutter, the system adapts to keep material flow smooth.

Beyond size, the system’s structural specs are designed for industrial durability. It features 8–13 storage floors, giving you ample space to organize raw materials or finished parts without cluttering your workshop floor. Each layer supports a robust 3T or 5T load—enough to handle thick steel sheets, heavy aluminum plates, or dense copper coils. This high load capacity means you won’t need separate storage racks for heavy materials; the system doubles as both a handling tool and organized storage, maximizing your space efficiency.

For movement, the system relies on a linear guide rail + chain setup paired with chain drive transmission. This combination delivers two critical benefits: precision and reliability. The linear guide rails ensure materials glide smoothly without shifting, even when carrying maximum loads, while the chain drive provides consistent power transfer—eliminating jams or slowdowns that disrupt production. When it comes to speed, the system keeps pace with your laser cutter: vertical lifting speed reaches 9m/min, and inlet/outlet speeds hit 12m/min. This means raw sheets move from storage to the laser table in seconds, and finished parts are unloaded just as fast—so your laser cutter never sits idle waiting for material.

To protect delicate or thin sheets, the system offers optional plate support. This customizable add-on prevents warping during transport, ensuring thin materials (like 0.5mm stainless steel) stay flat and aligned—critical for maintaining cut quality. Whether you’re handling heavy plates or fragile sheets, the system’s specs are tailored to keep your materials safe and your workflow on track.

Automation That Redefines Productivity: Core Features

The true power of Herochu’s Loading/unloading System lies in its automation capabilities—features designed to cut labor costs, reduce errors, and keep your production line running 24/7 if needed.

Independent Vacuum Loading & Unloading

At the heart of the system is an independent vacuum loading and unloading unit. Unlike basic systems that rely on mechanical clamps (which can scratch or damage materials), the vacuum system uses controlled suction to lift and move sheets gently. This not only protects delicate surfaces but also ensures a secure grip on even irregularly shaped materials. The independent design means loading and unloading can happen simultaneously: while the system unloads a finished part from the laser cutter, it’s already fetching the next raw sheet from storage. This parallel workflow cuts cycle times by up to 40%, keeping your laser cutter operating at peak capacity.

Fully Automatic & Intelligent Operation

Forget about constant operator oversight. The system runs on fully automatic, intelligent programming that syncs with your fiber laser cutter. Once you input your production schedule, the system handles the rest: it retrieves the correct raw sheet from the appropriate storage floor, loads it onto the laser table with precision, waits for the cut to finish, then unloads the finished part (and separates scrap skeletons, if needed) before repeating the process. This “lights-out” capability lets you run production during off-hours—nights, weekends, or shifts with limited staff—without sacrificing quality or safety. For businesses struggling to recruit reliable operators, this feature is a game-changer: it reduces labor needs while increasing output.

Multi-Level Storage for Space Optimization

With 8–13 storage floors, the system turns vertical space into usable storage. This is a lifesaver for workshops with limited floor space: instead of spreading materials across pallets or separate racks (which take up valuable room and increase the risk of damage), you can store everything in one centralized system. The storage floors are adjustable, too—so you can customize the height between levels to fit different sheet thicknesses. Whether you’re storing 10mm steel plates or 2mm aluminum sheets, the system keeps materials organized and easily accessible. This not only saves space but also cuts down on time wasted searching for the right material.

Automatic Loading Platform with Forklift Coupling

Urgent orders happen—and the system is built to handle them without disrupting your schedule. It includes an automatic loading platform that connects directly to forklifts. If you need to prioritize a rush job, simply use a forklift to load the urgent material onto the platform; the system recognizes the new sheet, pauses its current cycle (without losing progress), and processes the urgent order first. Once done, it seamlessly resumes the original schedule. This flexibility ensures you never have to turn down last-minute orders or delay existing ones—keeping your customers happy and your production line agile.

EtherCAT Bus Communication for Seamless Integration

Modern manufacturing relies on connected systems—and Herochu’s Loading/unloading System is designed to fit into your smart workshop. It uses EtherCAT Bus communication, a fast, reliable industrial protocol that lets the system connect with your fiber laser cutter, ERP software, or other automation tools (like Herochu’s Heavy Duty Roll Out Metal Structure Racks). This integration means real-time data sharing: you can track material usage, monitor production progress, and adjust schedules from a single dashboard. For example, if the system detects low stock of a specific material, it can send an alert to your inventory team—preventing unexpected downtime. This level of connectivity turns the system from a standalone tool into a central part of your smart manufacturing ecosystem.

Customizable to Your Workshop: No One-Size-Fits-All Solutions

Herochu knows that every workshop has unique needs. A small fabricator handling custom parts has different requirements than a large manufacturer running high-volume production. That’s why the Loading/unloading System for Fiber Laser Cutting Machine is fully customizable, starting with:

- Size Matching: Choose from 3015mm to 6025mm to fit your laser cutter’s working area. If your laser cutter has a non-standard size, we can build a custom system to match—no need to modify your existing equipment.

- Load Capacity: Opt for 3T or 5T per layer, or request a higher capacity (up to 8T) for extra-heavy materials (e.g., thick steel plates for construction).

- Storage Configuration: Adjust the number of storage floors (8–13) or the height between levels to fit your material inventory. We can also add dedicated scrap storage floors to keep waste separate from raw materials.

- Add-Ons: Beyond optional plate support, we offer extras like automated scrap separation (to remove waste without operator input), barcode scanning (to track materials automatically), or climate control (for sensitive materials like copper).

Every customization is tested by Herochu’s engineering team to ensure it works in harmony with your laser cutter and existing workflow. Whether you’re retrofitting an old workshop or building a new production line, we’ll design a system that fits your space, your materials, and your budget.

Certified Quality: CE, EU, ISO 9001—Compliance You Can Trust

When investing in industrial automation, quality and safety are non-negotiable. Herochu’s Loading/unloading System meets or exceeds global standards, backed by three critical certifications:

- ISO 9001: This certification ensures consistent quality in every component—from the linear guide rails to the vacuum pumps. Our manufacturing process is audited annually to maintain ISO 9001 compliance, so you know every system is built to last. We use high-grade steel for the frame, industrial-grade chains for transmission, and durable vacuum seals that resist wear—even after years of daily use.

- CE & EU: For businesses operating in the European Union or exporting to EU markets, CE compliance is mandatory. The system meets all EU safety, health, and environmental regulations: it includes emergency stop buttons, protective guards around moving parts, and automated error detection (if a sheet shifts or a sensor fails, the system pauses immediately to prevent damage or injury). It also uses energy-efficient motors that reduce power consumption—aligning with EU environmental standards.

- Rigorous Testing: Before any system ships, it undergoes 72 hours of continuous operation testing. We simulate real-world conditions: loading and unloading different material types (steel, aluminum, copper), running urgent orders, and testing communication with a fiber laser cutter. This ensures the system works flawlessly from day one—no costly downtime or adjustments after installation.

Solving Today’s Manufacturing Challenges: Why This System Is a Must-Have

Modern manufacturers face a host of challenges—rising labor costs, tight deadlines, limited space, and the need to adapt to small-batch orders. Herochu’s Loading/unloading System directly addresses these pain points:

- Cut Labor Costs: By automating loading, unloading, and storage, the system reduces the number of operators needed for material handling. Customers report a 35–50% drop in labor costs related to laser cutting within the first year. For example, a medium-sized fabricator that previously needed two operators to handle materials can now run the same workflow with one—freeing up staff for higher-value tasks like quality control or design.

- Minimize Material Waste: Manual handling often leads to damaged sheets—scratches, dents, or misalignments that make materials unusable. The system’s vacuum lifting and precise movement reduce waste by up to 25%. For high-cost materials like stainless steel or titanium, this savings adds up quickly: a 25% reduction in waste on a

10,000monthlymaterialbudgetsaves

30,000 a year.

- Boost Throughput: With no manual delays, the system keeps your laser cutter running longer. Most customers see a 50–70% increase in output within months. For example, a laser cutter that previously processed 50 sheets a day can now handle 85–90 sheets—all without adding extra shifts.

- Optimize Space: The multi-level storage turns vertical space into usable area. A workshop with a 6025mm system can store up to 13 layers of materials in the same floor space that would previously hold just 2–3 pallets. This frees up room for additional equipment or more workstations—helping you grow without moving to a larger facility.

Herochu: Your Partner in Smart Manufacturing

When you buy a Herochu Loading/unloading System, you’re not just purchasing equipment—you’re partnering with a team that’s invested in your success. As both a manufacturer and trader, we control every step of the process: from designing the system to shipping it to your workshop. This vertical integration lets us offer competitive pricing (starting at $8,900) without cutting corners on quality.

Our support doesn’t end with delivery:

- Consultation: We start by learning about your workshop—your laser cutter size, material types, production volume, and space constraints. Our team recommends a configuration that fits your needs, no pushy sales tactics.

- Custom Design: If you need a non-standard size or add-ons, our engineers create 3D renderings so you can visualize the system before production. We adjust the design until it’s perfect for your workflow.

- Installation: Our certified technicians install the system on-site, calibrating it to your laser cutter and testing it to ensure seamless integration. We also train your team on how to operate, maintain, and troubleshoot the system—with easy-to-follow guides and hands-on sessions.

- After-Sales Support: We offer 24/7 technical support for urgent issues. If a part needs replacement (like a chain or vacuum seal), we stock spare parts in global warehouses—so you get what you need in days, not weeks. We also provide annual maintenance checks to keep the system running like new.

- OEM/ODM Services: Need to brand the system with your company logo or integrate custom software? We offer OEM/ODM options to make the system uniquely yours.

We export our systems to markets worldwide, with a track record of success in industries like automotive (Netherlands), aerospace (South Africa), and construction (Serbia). Our customer satisfaction rate is 100%—because we don’t just sell systems; we help you build more efficient, profitable operations.

Ideal Applications: Where the System Shines

Herochu’s Loading/unloading System for Fiber Laser Cutting Machine is versatile enough to serve a wide range of industries:

- Automotive Manufacturing: Handle large sheets for body panels or chassis components. The 6025mm size and 5T load capacity easily manage heavy steel sheets, while the forklift coupling handles urgent orders (like last-minute parts for a production run).

- Metal Fabrication: Process small-batch custom parts and high-volume orders alike. The multi-level storage keeps different material types organized, and the automatic operation reduces labor needs—perfect for shops with fluctuating order volumes.

- Aerospace & Defense: Cut precision parts from delicate materials (like titanium or Inconel). The vacuum loading system protects sensitive surfaces, and the EtherCAT communication integrates with quality control tools to ensure compliance with strict industry standards.

- Electronics: Process small, thin sheets for circuit boards or enclosures. The optional plate support prevents warping, and the fast inlet/outlet speeds keep up with high-precision, low-volume cuts.

- Construction: Handle oversized sheets for roofing, siding, or structural steel. The 6025mm working area and 5T load capacity manage large materials, while the vertical storage saves floor space in busy construction yards.

Why Choose Herochu Over Competitors?

In a market filled with generic material handling systems, Herochu’s Loading/unloading System stands out for three key reasons:

- Laser-Centric Design: Unlike generic loading systems that “work with” laser cutters, ours is engineered specifically for fiber laser cutting. Every feature—from the 12m/min inlet speed to the EtherCAT communication—is designed to sync with laser cutters, ensuring no bottlenecks.

- True Customization: Competitors often offer limited “options”; we build systems tailored to your exact needs. Whether you need a 5T load capacity or a custom size, we don’t force you to compromise.

- Value for Money: Starting at $8,900, our system offers more features (vacuum loading, forklift coupling, EtherCAT) than similarly priced competitors. Plus, our 100% customer satisfaction rate means you’re not just buying a system—you’re buying peace of mind.

Ready to Transform Your Material Handling?

Herochu’s Loading/unloading System for Fiber Laser Cutting Machine isn’t just an investment in equipment—it’s an investment in your workshop’s efficiency, profitability, and future. By automating material handling, you’ll cut labor costs, reduce waste, and keep your laser cutter running at peak capacity.

Contact our team today to request a free quote, schedule a virtual demo, or discuss your customization needs. We’ll help you design a system that fits your budget, your space, and your production goals.

Herochu: Smart Material Handling for Smarter Manufacturing.

Q1: What steps should I take to start the procurement process?

You may get in touch with our backend technical staff first. Based on your specific parameters, we will formulate a suitable technical solution and provide a quotation. Alternatively, you can leave your contact details—such as WhatsApp, WeChat, or email address—and our professional sales team will reach out to you proactively.

Q2: How can I inform you of my need for suitable shelves?

You can share key information with us, including the type of items you plan to store on the shelves, the dimensions of those items, the quantity of shelves required, and any other specific details you have. With this information, we will develop a professional solution tailored to your needs. If you prefer, you can also leave your contact information, and our specialized team will contact you to address your questions.

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

To determine the right option, two key factors need to be considered first:

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

For a more accurate recommendation based on your specific needs, please leave your contact information, and we will provide targeted service.

Q4: Do you offer on-site installation and debugging services?

Yes, we do. We can dispatch professional technicians to your factory to carry out on-site installation and debugging of the robotic arm, and we will continue working until the equipment completes a successful trial operation. Our team has provided such services in many countries, including South Africa, the United States, Russia, South Korea, Qatar, Egypt, Lebanon, and Mexico.

Q5: What measures do you take to ensure product quality?

We have a comprehensive quality assurance system, supported by the following key measures:

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Our factory is located in Jinan, Shandong Province, China, specifically at No. 10 Industrial Park, Jiyang Street. It features a modern, standard workshop covering an area of 10,000 square meters.

Q7: How can I verify your company’s strength?

We offer two convenient ways for you to assess our company’s capabilities:

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

We are Jinan Constant Storage Machinery Manufacturing Co., Ltd., a high-tech enterprise that integrates research and development, production, sales, installation, and after-sales service. Our core product range includes intelligent sheet metal material warehouses, drawer-type sheet metal shelves, telescopic cantilever shelves, servo swing arm manipulators, gantry loading and unloading manipulators, fully automatic loading and unloading systems, and heavy-duty sheet metal and pipe storage shelves. Equipped with a professional technical team and advanced production equipment, we are committed to providing high-quality, high-performance mechanical products and customized solutions to customers around the world.

PRODUCTS

-

Fiber Laser Automation Systems

Loading/unloading System for Fiber Laser Cutting Machine

Read moreRated 0 out of 5 -

Fiber Laser Automation Systems

Automatic Loading and Unloading System for Fiber Laser

Read moreRated 0 out of 5 -

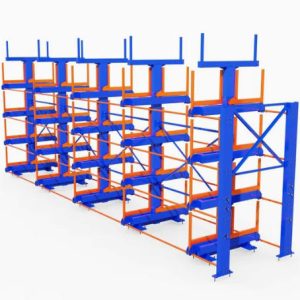

Heavy Duty Cantilever Racking System

Telescopic Cantilever Shelves Long Materials Storage

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Pipe Telescopic Cantilever Shelf Metal Sheet Warehouse Storage Rack

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Intelligent Sheet Metal Storage System

Read moreRated 0 out of 5