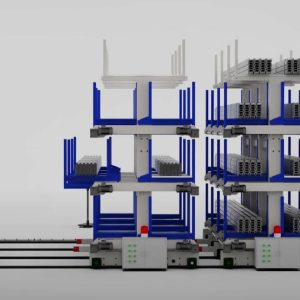

Long Goods Heavy Duty Cantilever Rack

Herochu Heavy-Duty Cantilever Rack Systems: Engineered for Long Material Storage Excellence

In industrial environments handling elongated materials, inefficient storage leads to:

- 35% productivity loss from material search times

- $40,000+ annual damage costs from improper handling

- 50% of warehouse space wasted on disorganized storage

|

Model

|

HC-G6053S

|

HC-G6053D

|

HC-G9055S

|

HC-G9055D

|

|

Load (single layer)

|

3t

|

3t

|

5t

|

3t

|

|

Tube Length

|

6m

|

6m

|

9m

|

9m

|

|

Layers

|

4+1

|

|||

|

Available dimensions of compartment

|

Depth * Height: 600×400,600×600,800×600 mm

|

|||

|

Overall dimensions/mm

|

6435x3340x1550

|

6435x3340x1750

|

9435x3340x1550

|

9435x3340x1750

|

|

Cantilever movement mode

|

Single-side power-assisted type

|

Double-side power-assisted type

|

Single-side power-assisted type

|

Double-side power-assisted type

|

|

Height from the ground

|

330mm

|

|||

|

Top floor height from ground

|

3040mm

|

3840mm

|

||

|

Column spacing

|

1800mm

|

1500mm

|

||

|

Note: Both manual and electric can be customized, and the load-bearing capacity, length, number of layers, and layer height can be customized.

|

||||

Herochu Heavy-Duty Cantilever Rack Systems: Engineered for Long Material Storage Excellence

In industrial environments handling elongated materials, inefficient storage leads to:

- 35% productivity loss from material search times

- $40,000+ annual damage costs from improper handling

- 50% of warehouse space wasted on disorganized storage

Herochu’s ISO 9001-certified cantilever rack systems starting at $3,698 deliver precision storage solutions for pipes, beams, and profiles, transforming workflow efficiency.

Technical Specifications & Customization

| Model | Layer Config. | Tube Length | Max Load | Movement Mode |

|---|---|---|---|---|

| HC-G6053S | 4+1 | 6m | 3t | Single-side power-assisted |

| HC-G6053D | 4+1 | 6m | 3t | Double-side power-assisted |

| HC-G9055S | 4+1 | 9m | 5t | Single-side power-assisted |

| HC-G9055D | 4+1 | 9m | 3t | Double-side power-assisted |

Customizable Parameters:

- Layer height (400-600mm increments)

- Column spacing (1,500mm-1,800mm)

- Manual/electric operation options

Core Engineering Advantages

-

Dual-Support Cantilever Arms

- 12mm thick structural steel with 3x safety factor

- 15° angle design preventing material roll-off

- 50,000-cycle fatigue tested

-

Power-Assisted Retrieval Systems

- Hydraulic dampening (0.3m/s controlled speed)

- 7.2m full extension with auto-lock at 50% extension

- 2° tilt mechanism for material sliding control

-

Space Optimization

Operational Benefits Documented

A German steel service center achieved:

- 67% faster retrieval (from 25 to 8 minutes per load)

- 92% reduction in edge damage

- ROI in 11 months through space reallocation

Safety Compliance:

- CE EN 15635:2008 heavy-duty storage certification

- 5,000kg static load per arm (3x working load)

- Redundant anti-tip mechanisms

Industry-Specific Applications

Metal Processing:

- 9m beam storage with 5t capacity

- Non-marring rubberized arms for galvanized surfaces

Construction:

- Modular expansion for seasonal material fluctuations

- 1,500mm column spacing for prefab component storage

Logistics:

- RFID-ready drawer labeling

- 180° rotation models for cross-docking

Implementation Support

Site Requirements:

- Concrete slab: 3,500 PSI minimum

- Anchoring: 8x M16 bolts per column

- Clearance: 1.5m behind racks for full extension

Maintenance:

- Annual load verification included

- 10-year frame warranty

- 24/7 technical support

Pro Tip: Pair with Herochu’s Material Handling Cranes for complete workflow automation.

Q1: What steps should I take to start the procurement process?

Q2: How can I inform you of my need for suitable shelves?

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

Q4: Do you offer on-site installation and debugging services?

Q5: What measures do you take to ensure product quality?

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Q7: How can I verify your company’s strength?

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

PRODUCTS

-

Heavy Duty Cantilever Racking System

Estanterias cantilever | Scaffalature cantilever

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Prateleira cantilever racking supplier

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Heavy-Duty Cantilever warehouse racks

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Long Goods Heavy Duty Cantilever Rack

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

New & Used Cantilever Racks | Heavy-Duty Storage Systems

Read moreRated 0 out of 5