Optimizing Warehouse Efficiency with Pipe Racking systems

Long material has a sneaky way of eating a warehouse alive. One week a bundle of 6-inch schedule-40 pipe is parked across two aisle stripes; a month later the same stock has multiplied into a metallic hedge maze that forces forklifts on detours and hides the bar-code labels you swear you printed. Floor-stacking looks free until you measure the creeping cost: lost labor hours, dented profiles, toppled bundles and the ever-present risk of an OSHA citation when a two-ton length rolls off an uneven pile. Herochu pipe-racking systems convert that chaos into a vertical, gravity-safe filing cabinet where every tube, bar or beam is visible, reachable and accounted for in under thirty seconds.

Optimizing Warehouse Efficiency with Pipe Racking Systems That Pay for Themselves

Herochu Cantilever & Vertical Pipe Racks | Tailor-made for your yard, starting at $3,099 | CE, UE, ISO 9001 certified

Herochu Cantilever & Vertical Pipe Racks | Tailor-made for your yard, starting at $3,099 | CE, UE, ISO 9001 certified

Long material has a sneaky way of eating a warehouse alive. One week a bundle of 6-inch schedule-40 pipe is parked across two aisle stripes; a month later the same stock has multiplied into a metallic hedge maze that forces forklifts on detours and hides the bar-code labels you swear you printed. Floor-stacking looks free until you measure the creeping cost: lost labor hours, dented profiles, toppled bundles and the ever-present risk of an OSHA citation when a two-ton length rolls off an uneven pile. Herochu pipe-racking systems convert that chaos into a vertical, gravity-safe filing cabinet where every tube, bar or beam is visible, reachable and accounted for in under thirty seconds.

Why Cantilever? Because Walls Are Overrated

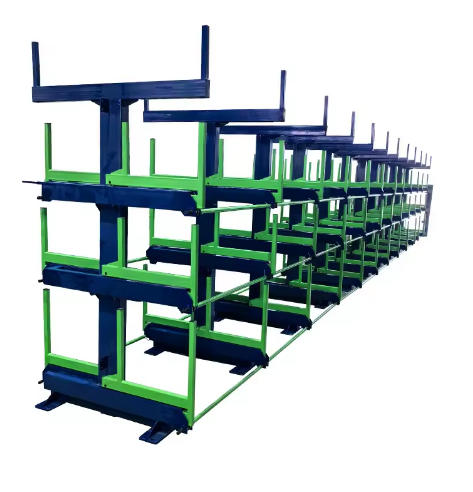

Traditional selective racks need a front column, turning long stock storage into a game of thread-the-needle. Herochu cantilever racks remove the obstacle: arms project from a single central column, leaving the face wide open. Forklifts drive straight in, deposit a bundle and back out—no diagonal gymnastics, no scratched paint. Arms adjust on 50 mm increments, so today’s 20-foot conduit can live on the same beam as next month’s 40-foot casing. Load capacities start at 1,500 lb per arm and climb to 5,500 lb, meaning a four-arm bay can park 22,000 lb of carbon steel in the footprint of a standard pallet position. Multiply by ten bays and you have 220,000 lb of organized steel hovering over floor space you can now lease to another tenant or fill with a second paint line.

Traditional selective racks need a front column, turning long stock storage into a game of thread-the-needle. Herochu cantilever racks remove the obstacle: arms project from a single central column, leaving the face wide open. Forklifts drive straight in, deposit a bundle and back out—no diagonal gymnastics, no scratched paint. Arms adjust on 50 mm increments, so today’s 20-foot conduit can live on the same beam as next month’s 40-foot casing. Load capacities start at 1,500 lb per arm and climb to 5,500 lb, meaning a four-arm bay can park 22,000 lb of carbon steel in the footprint of a standard pallet position. Multiply by ten bays and you have 220,000 lb of organized steel hovering over floor space you can now lease to another tenant or fill with a second paint line.

Vertical Racks for the Short, the Odd and the Expensive

Not every pipe justifies horizontal real estate. Short off-cuts, stainless instrument tube or high-value copper nickel lengths often disappear when laid flat. Herochu vertical racks stand them on end in segmented cradles, turning a 2 m × 0.6 m corner of concrete into a 3 m high library. Dividers keep alloys from kissing, preventing galvanic stains that ruin passivation. A single operator can flip through pieces like vinyl records, cutting search time from twenty minutes to twenty seconds. The base is fully open for pallet jack or forklift entry, so restocking still happens at speed.

Not every pipe justifies horizontal real estate. Short off-cuts, stainless instrument tube or high-value copper nickel lengths often disappear when laid flat. Herochu vertical racks stand them on end in segmented cradles, turning a 2 m × 0.6 m corner of concrete into a 3 m high library. Dividers keep alloys from kissing, preventing galvanic stains that ruin passivation. A single operator can flip through pieces like vinyl records, cutting search time from twenty minutes to twenty seconds. The base is fully open for pallet jack or forklift entry, so restocking still happens at speed.

Modular DNA

Start with one bay, add another next quarter, bridge them with a sway brace, and you have a double-sided monster that shares columns and cuts steel cost per position by 18 %. All components bolt together with grade 8 hardware; no on-site welding, no hot-work permit, no production holiday. Powder-coat finish is salt-spray rated for 1,000 hours, so the rack can live under a canopy outdoors without blooming rust that ends up on your polished round bars.

Start with one bay, add another next quarter, bridge them with a sway brace, and you have a double-sided monster that shares columns and cuts steel cost per position by 18 %. All components bolt together with grade 8 hardware; no on-site welding, no hot-work permit, no production holiday. Powder-coat finish is salt-spray rated for 1,000 hours, so the rack can live under a canopy outdoors without blooming rust that ends up on your polished round bars.

Safety Up, Insurance Down

A freestanding bundle is an unguided missile. Once pipes are cradled in a Herochu rack, the center of gravity drops below the arm height and the chance of accidental roll-off falls to near zero. Forklift impact is absorbed by 6 mm arm end-stops and a 10 mm column base plate. These are not marketing numbers—they are the calculations our engineers stamp before the CE logo goes on. Plants that replaced floor piles with engineered racks have seen worker-comp claims drop 35 % and general-liability premiums fall an average of 9 % the following policy year. In many cases the annual saving alone covers the finance payment on the steel.

A freestanding bundle is an unguided missile. Once pipes are cradled in a Herochu rack, the center of gravity drops below the arm height and the chance of accidental roll-off falls to near zero. Forklift impact is absorbed by 6 mm arm end-stops and a 10 mm column base plate. These are not marketing numbers—they are the calculations our engineers stamp before the CE logo goes on. Plants that replaced floor piles with engineered racks have seen worker-comp claims drop 35 % and general-liability premiums fall an average of 9 % the following policy year. In many cases the annual saving alone covers the finance payment on the steel.

Space Math That Works in Any Zip Code

A typical outdoor storage pad allows 12-foot aisles. Floor-stacking 200 tons of 6-inch pipe consumes 4,800 ft². Switch to a double-sided cantilever system 12 feet high and the same tonnage occupies 960 ft²—an 80 % reduction. At average U.S. industrial rent of $6.50/ft², that liberation is worth $24,960 per year in recovered real estate. Over five years you have buried the cost of the rack and created room for future growth without pouring another yard of concrete.

A typical outdoor storage pad allows 12-foot aisles. Floor-stacking 200 tons of 6-inch pipe consumes 4,800 ft². Switch to a double-sided cantilever system 12 feet high and the same tonnage occupies 960 ft²—an 80 % reduction. At average U.S. industrial rent of $6.50/ft², that liberation is worth $24,960 per year in recovered real estate. Over five years you have buried the cost of the rack and created room for future growth without pouring another yard of concrete.

Outdoor Tough, Indoor Polite

Galvanized finish? Done. Hot-dip after fabrication for arms that will sit under the Arizona sun. Need a rack inside a cleanroom? Send us the FDA paint spec and we will bake on a low-VOC epoxy that passes swab tests. Adjustable feet compensate for sloped pavement; roof arms accept tarpaulin poles to create an instant canopy, keeping UV off UV-stabilized pipe. However hostile your environment, we spec a metallurgy that outlives the stock it holds.

Galvanized finish? Done. Hot-dip after fabrication for arms that will sit under the Arizona sun. Need a rack inside a cleanroom? Send us the FDA paint spec and we will bake on a low-VOC epoxy that passes swab tests. Adjustable feet compensate for sloped pavement; roof arms accept tarpaulin poles to create an instant canopy, keeping UV off UV-stabilized pipe. However hostile your environment, we spec a metallurgy that outlives the stock it holds.

From Quote to Concrete in Ten Days

Upload a spreadsheet—length, diameter, weight, pick frequency. Our configurator spits out a 3-D model, aisle width, forklift clearance and total cost within two business hours. Approve, pay a 40 % deposit and production starts the same afternoon. Standard bays ship in ten calendar days; custom heights or sealed-bearing crank-assist add three more. A QR code on every crate links to an animated assembly video so your maintenance crew can erect a ten-bay run before the weekend beer call.

Upload a spreadsheet—length, diameter, weight, pick frequency. Our configurator spits out a 3-D model, aisle width, forklift clearance and total cost within two business hours. Approve, pay a 40 % deposit and production starts the same afternoon. Standard bays ship in ten calendar days; custom heights or sealed-bearing crank-assist add three more. A QR code on every crate links to an animated assembly video so your maintenance crew can erect a ten-bay run before the weekend beer call.

Accessories That Turn Steel into a Database

-

Color-coded arm caps: red for carbon, blue for stainless, yellow for aluminum—visual segregation that kills mix-ups.

-

Magnetic slot-in labels: bar-code or RFID ready, swap in seconds when stock turns.

-

Crank-out loading platform: drops to 400 mm for walk-behind stacker pickup, rises to 1,200 mm for truck bed height—ergonomic and forklift-free.

-

Removable pipe saddles: V-shaped cradles keep bundles centred, preventing ovality on thin-wall tube.

Real Yards, Real Numbers

Gulf Coast Spool Works had 18 acres but could not find 40-foot chrome-moly among the piles. After installing 1,200 linear feet of Herochu cantilever rack, they cut retrieval time by 68 % and released 2.3 acres for a new blasting bay. Annualised labor saving: $310,000. Pay-back: 4.7 months.

A Scandinavian stainless distributor switched to vertical racks for 6 m off-cuts. Damage claims from scratched tube dropped 92 % the first year, saving €42,000 in rejected shipments and preserving a key aerospace contract.

Gulf Coast Spool Works had 18 acres but could not find 40-foot chrome-moly among the piles. After installing 1,200 linear feet of Herochu cantilever rack, they cut retrieval time by 68 % and released 2.3 acres for a new blasting bay. Annualised labor saving: $310,000. Pay-back: 4.7 months.

A Scandinavian stainless distributor switched to vertical racks for 6 m off-cuts. Damage claims from scratched tube dropped 92 % the first year, saving €42,000 in rejected shipments and preserving a key aerospace contract.

The Quiet Sustainability Win

Every bundle that no longer needs re-blasting because it sat in mud equals 120 kWh of compressor and blast wheel energy saved. Organised racks allow first-in-first-out rotation, cutting over-age inventory that would otherwise be downgraded or melted. If your ESG report needs Scope 4 metrics, pipe racking delivers them in steel and kilowatt-hours.

Every bundle that no longer needs re-blasting because it sat in mud equals 120 kWh of compressor and blast wheel energy saved. Organised racks allow first-in-first-out rotation, cutting over-age inventory that would otherwise be downgraded or melted. If your ESG report needs Scope 4 metrics, pipe racking delivers them in steel and kilowatt-hours.

Pricing That Scales with Stress, Not Hype

Single-sided starter bay, 3 m column, four arms, 1,500 lb per arm: $3,099.

Double-sided monster, 6 m column, twelve arms, 5,500 lb per arm: $11,440.

Add-on bay (shares column): $1,849.

Galvanizing surcharge: 18 %.

Sealed-bearing crank-assist kit: $650 per arm.

All prices FOB Shanghai; landed-cost calculator live on herochu.com.

Single-sided starter bay, 3 m column, four arms, 1,500 lb per arm: $3,099.

Double-sided monster, 6 m column, twelve arms, 5,500 lb per arm: $11,440.

Add-on bay (shares column): $1,849.

Galvanizing surcharge: 18 %.

Sealed-bearing crank-assist kit: $650 per arm.

All prices FOB Shanghai; landed-cost calculator live on herochu.com.

Stop Paying Rent on Disorder

Long material does not need to own your floor, your labor or your liability. Herochu pipe-racking systems turn random bundles into a vertical filing cabinet that feeds machines, not frustration. Reclaim square footage, slash search time, protect expensive stock and send a clear message to every auditor, insurer and customer who walks the yard: we run steel, steel does not run us. Configure your rack tonight, bolt it together next week and watch the daily shuffle disappear forever.

Long material does not need to own your floor, your labor or your liability. Herochu pipe-racking systems turn random bundles into a vertical filing cabinet that feeds machines, not frustration. Reclaim square footage, slash search time, protect expensive stock and send a clear message to every auditor, insurer and customer who walks the yard: we run steel, steel does not run us. Configure your rack tonight, bolt it together next week and watch the daily shuffle disappear forever.

Q1: What steps should I take to start the procurement process?

You may get in touch with our backend technical staff first. Based on your specific parameters, we will formulate a suitable technical solution and provide a quotation. Alternatively, you can leave your contact details—such as WhatsApp, WeChat, or email address—and our professional sales team will reach out to you proactively.

Q2: How can I inform you of my need for suitable shelves?

You can share key information with us, including the type of items you plan to store on the shelves, the dimensions of those items, the quantity of shelves required, and any other specific details you have. With this information, we will develop a professional solution tailored to your needs. If you prefer, you can also leave your contact information, and our specialized team will contact you to address your questions.

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

To determine the right option, two key factors need to be considered first:

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

For a more accurate recommendation based on your specific needs, please leave your contact information, and we will provide targeted service.

Q4: Do you offer on-site installation and debugging services?

Yes, we do. We can dispatch professional technicians to your factory to carry out on-site installation and debugging of the robotic arm, and we will continue working until the equipment completes a successful trial operation. Our team has provided such services in many countries, including South Africa, the United States, Russia, South Korea, Qatar, Egypt, Lebanon, and Mexico.

Q5: What measures do you take to ensure product quality?

We have a comprehensive quality assurance system, supported by the following key measures:

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Our factory is located in Jinan, Shandong Province, China, specifically at No. 10 Industrial Park, Jiyang Street. It features a modern, standard workshop covering an area of 10,000 square meters.

Q7: How can I verify your company’s strength?

We offer two convenient ways for you to assess our company’s capabilities:

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

We are Jinan Constant Storage Machinery Manufacturing Co., Ltd., a high-tech enterprise that integrates research and development, production, sales, installation, and after-sales service. Our core product range includes intelligent sheet metal material warehouses, drawer-type sheet metal shelves, telescopic cantilever shelves, servo swing arm manipulators, gantry loading and unloading manipulators, fully automatic loading and unloading systems, and heavy-duty sheet metal and pipe storage shelves. Equipped with a professional technical team and advanced production equipment, we are committed to providing high-quality, high-performance mechanical products and customized solutions to customers around the world.

PRODUCTS

-

Heavy Duty Cantilever Racking System

Cantilever Racks & Heavy-Duty Shelf Systems for Warehouses

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Industrial Roll-out Telescopic Cantilever Rack

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Storage solution for long timber packs

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Heavy duty Storage racks for steel profiles

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Storage steel sheets racks measuring 1500×3000 or 3500mm for 3t sheets

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Optimizing Warehouse Efficiency with Pipe Racking systems

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Industry Pipe Storage and Racking Solutions

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Cantilever Steel Bar, Tubing & Pipe Storage Racks

Read moreRated 0 out of 5