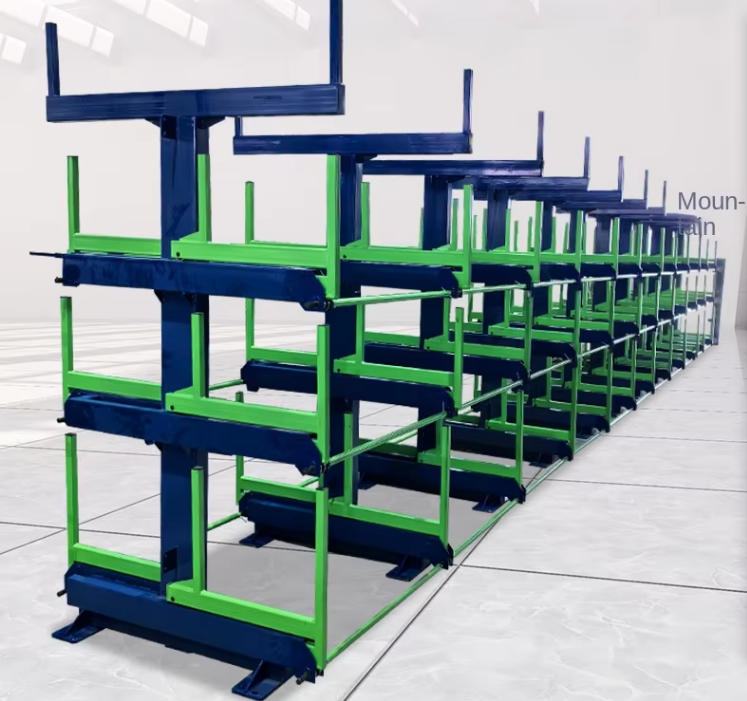

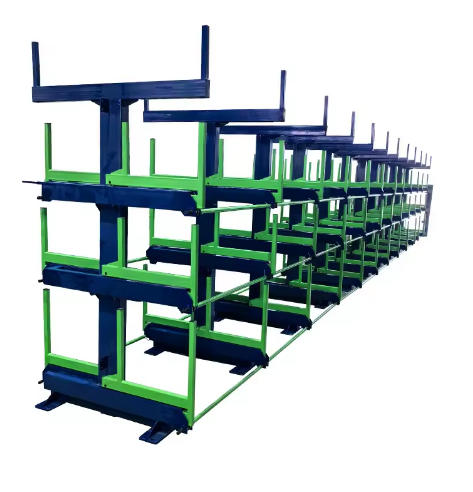

Pipe Rack Storage Systems

A cantilever rack, by eliminating front-column obstructions, creates a completely open-faced storage bay. This is its single greatest advantage. A forklift or overhead crane operator can approach the load directly, from any point along its length, without navigating around posts or other vertical impediments. This “direct-line” access is what slashes retrieval times from tens of minutes to a matter of moments.

The Unseen Geometry of Your Workshop: Mastering Long-Form Storage with Herochu Pipe Rack Systems

In the complex geometry of a modern fabrication shop, the straight line is both a product and a problem. Pipes, tubes, extrusions, and structural beams—the linear elements that form the skeleton of countless projects—are notoriously difficult to corral. Tossed in a corner, leaned against a wall, or laid flat in a tangled heap, they consume a disproportionate amount of your most valuable real estate: clear floor space. More critically, they create a persistent, low-grade operational crisis. The search for a specific 8-meter stainless steel tube can devour 30 minutes of skilled labor. The risk of a stack collapsing or a beam rolling underfoot is a constant, unspoken anxiety.

The common pallet, the workhorse of modern logistics, is useless here. You can’t palletize the unpalletizable. This is the storage challenge that demands a specialized solution, one that respects the unique physics and logistics of long, heavy loads. The Herochu Pipe Rack Storage System is not just another piece of workshop equipment; it is a three-dimensional blueprint for order, safety, and radical efficiency in handling the materials that defy conventional storage.

The High Cost of Chaos: When Your Linear Inventory Creates a Tangled Workflow

Before a storage solution can be evaluated, the true cost of the problem must be understood. The disorganized storage of long materials isn’t just messy; it’s a multi-faceted drain on your operation:

-

The Productivity Sink: The average time spent locating and extracting a specific pipe or tube from a disorganized pile can range from 15 to 45 minutes. This isn’t just lost labor time; it’s time your press brake, welding station, or assembly line is left waiting, creating a bottleneck that ripples through your entire production schedule.

-

The Damage Multiplier: When materials are tangled together, every retrieval risks cosmetic scratches, deep gouges, or even bending. For expensive materials like polished copper tubing or anodized aluminum extrusions, a single scratch can render a length useless, turning potential profit into immediate scrap.

-

The Safety Liability: Unsecured stacks of long, heavy materials are inherently unstable. A forklift nicking a pile, a worker tripping over a protruding end, or a simple shift in weight can lead to a catastrophic collapse, with consequences ranging from minor injury to devastating workplace accidents.

-

The Inventory Blind Spot: How do you perform an accurate stocktake on a tangled pile of 200 identical-looking steel tubes? You can’t. This leads to phantom inventory, duplicate orders, and costly production delays when a supposedly “in-stock” item cannot be found.

The Cantilever Revolution: Why It’s the Default for a Reason

Among the choices for fabricators, the cantilever rack stands apart. It is the foundational technology for long-load storage because its design principles directly attack the core inefficiencies of the problem. The Herochu system refines this principle to an art form.

The Anatomy of Access:

A cantilever rack, by eliminating front-column obstructions, creates a completely open-faced storage bay. This is its single greatest advantage. A forklift or overhead crane operator can approach the load directly, from any point along its length, without navigating around posts or other vertical impediments. This “direct-line” access is what slashes retrieval times from tens of minutes to a matter of moments.

The Herochu Cantilever Advantage:

While the basic cantilever concept is powerful, the execution defines its performance. Herochu racks are engineered with a focus on three critical attributes:

-

Uncompromising Structural Integrity: Fabricated from high-grade steel, our racks are built to handle not just the static weight, but the dynamic forces of loading and unloading. The robust uprights and braced columns provide a stable foundation, while the heavy-duty arms are designed with a slight upward tilt to prevent loads from accidentally sliding off.

-

Unparalleled Configurability: Your inventory is not static, and your storage shouldn’t be either. The ability to adjust the height of the arms on the columns is a transformative feature. One week you might need to store tall bundles of pipe; the next, you might need to reconfigure for multiple levels of shorter bar stock. This adaptability prevents storage obsolescence.

-

Optimized for Real-World Use: We understand that a rack doesn’t exist in isolation. Our designs account for the need for forklift access, the swing radius of overhead cranes, and the practical height limits for safe manual handling. This holistic approach ensures the system integrates seamlessly into your existing workflow, rather than forcing you to build a new workflow around it.

The Herochu Pipe Rack Portfolio: Scalable Solutions from Standard to Heavy-Duty

The true measure of a storage system is its ability to scale with your ambition. The Herochu portfolio is designed to provide a solution for every scale of operation, from the small job shop to the heavy industrial plant.

Standard Duty Workhorses (e.g., HC-G6053D):

Ideal for the high-mix fabricator, these units handle common lengths up to 6 meters with a solid 3-ton per layer capacity. They are the perfect antidote to workshop clutter, organizing a diverse inventory of tubing, trim, and structural components in a compact, accessible footprint.

Heavy-Duty Industrial Giants (e.g., HC-G12055D):

For enterprises dealing in the large-scale infrastructure, energy, or construction sectors, these are the titans of storage. Engineered for massive 12-meter lengths and a formidable 5-ton per layer capacity, they provide a safe, organized home for the materials that are too often left to the elements in a yard, protecting your capital and simplifying logistics.

The Bilateral vs. Unilateral Decision:

Our systems offer a choice between unilateral (single-sided) and bilateral (double-sided) configurations. A unilateral rack is perfect for placement against a wall, maximizing space in a narrower facility. A bilateral rack acts as a freestanding room divider, creating a high-density storage backbone that is accessible from both sides, effectively doubling your storage capacity within the same floor space.

Quantifying the Return: The Tangible Benefits of an Organized System

Investing in a Herochu Pipe Rack System is a strategic decision with a clear and calculable return. The benefits translate directly into financial and operational gains.

| Pain Point | Herochu Solution | Business Impact |

|---|---|---|

| Wasted Search Time | Open-front, 100% visible and accessible storage. | Slashes retrieval time by over 75%, freeing up skilled labor and eliminating machine downtime. |

| Material Damage | Individual, supported cradling on dedicated arms. | Dramatically reduces scrap and rework, protecting the value of expensive raw materials. |

| Safety Hazards | Eliminates unstable leaning stacks and tangled piles. | Creates a predictable, safe environment, reducing the risk of accidents and associated costs. |

| Inefficient Space Use | High-density vertical storage. | Recaptures up to 60% of floor space consumed by horizontal piles, enabling facility expansion without construction. |

| Poor Inventory Control | Logical, visible organization by type, size, and grade. | Enables accurate, visual stock management, preventing project delays and duplicate orders. |

Built for the Long Haul, Certified for Confidence

A Herochu system is a generational investment in your workshop’s infrastructure. Constructed from prime materials and featuring a durable powder-coated or galvanized finish, these racks are built to withstand decades of industrial use. This commitment to quality is externally validated by our CE, UKCA, and ISO 9001 certifications, providing you with independent assurance of the system’s structural integrity and safety.

Stop allowing your most challenging materials to dictate the limits of your shop’s efficiency and safety. It’s time to apply a disciplined, engineered solution to the problem of long-form storage.

The Herochu Pipe Rack Storage System, starting at $3,890, is that solution. It is the definitive tool for transforming a chaotic, high-liability area into a model of productivity and order.

Contact us today for a customized storage assessment. Let our experts show you how a tailored pipe rack system can unlock the hidden potential of your workshop, turning your linear inventory from a management headache into your most organized asset.

Q1: What steps should I take to start the procurement process?

Q2: How can I inform you of my need for suitable shelves?

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

Q4: Do you offer on-site installation and debugging services?

Q5: What measures do you take to ensure product quality?

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Q7: How can I verify your company’s strength?

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

PRODUCTS

-

Heavy Duty Cantilever Racking System

Cantilever Steel Bar, Tubing & Pipe Storage Racks

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Heavy Duty Sheet Metal Forklift Solutions

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Forklift for Metal Sheets – Efficient Handling Solutions

Read moreRated 0 out of 5