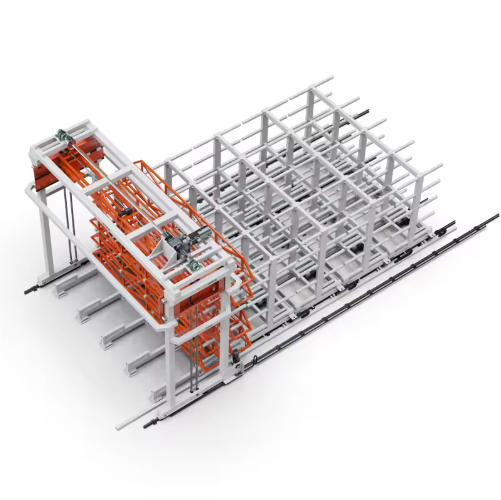

Pipe Store Long Span Goods Automated Storage System

Herochu’s system collects this data and presents it in easy-to-analyze reports, allowing you to identify inefficiencies (e.g., a slow retrieval process for a specific pipe type) and optimize workflows. You can also use this data to predict future demand: for example, if data shows you use 100 6-meter pipes per month, you can schedule reorders to avoid stockouts. This data-driven approach turns your storage system into a tool for continuous improvement.

Herochu Pipe Store Long Span Goods Automated Storage System: Redefine Efficiency for Long Material Handling

In industrial facilities—from steel mills and plumbing supply warehouses to construction material yards—storing and managing long, bulky items like pipes, profiles, and bars has long been a source of operational friction. Traditional methods—relying on manual forklifts, static cantilever racks, or floor stacking—often lead to wasted space, slow retrieval times, human error, and safety risks. Workers spend hours navigating cluttered aisles to locate a specific pipe length; valuable vertical space goes unused; and manual handling of heavy loads increases the risk of injuries and material damage. Herochu’s Pipe Store Long Span Goods Automated Storage System eliminates these pain points by integrating precision engineering, intelligent automation, and durable construction, creating a seamless solution for storing, accessing, and managing long-span goods.

Certified to meet CE, EU, and ISO 9001 standards, this system is built to withstand the rigors of industrial use—from heavy daily operations to exposure to dust, moisture, and temperature fluctuations—while adhering to global safety and quality benchmarks. Starting at $42,000 and fully customizable to your workshop’s layout, material types, and capacity needs, this system is not just a storage investment: it’s a strategic tool to boost productivity, reduce long-term costs, and future-proof your operations. Whether you’re storing 6-meter steel pipes, bundled aluminum profiles, or heavy-duty bars, Herochu’s system adapts to your workflow, turning disorganized material storage into a streamlined, data-driven hub.

The Core of Herochu’s Pipe Store Long Span Goods Automated Storage System

At its heart, this system is a cohesive integration of four key components—each designed to work in tandem to eliminate inefficiencies and enhance reliability. Unlike fragmented storage setups that require cobbling together separate tools, Herochu’s integrated design ensures every part communicates seamlessly, minimizing downtime and maximizing performance.

1. Loading & Unloading Gantry System: The Engine of Automated Movement

The gantry system is the workhorse of the operation, responsible for moving long-span goods in and out of storage with precision. Built as a heavy-duty bridge crane, it travels along dedicated guide rails (tailored to your workshop’s layout) and positions itself accurately over storage racks and material frames. This precision is critical: when handling a 6-meter pipe or a bundle of profiles, the gantry eliminates the guesswork of manual operation, ensuring materials are lifted, transported, and placed exactly where needed—no more accidental collisions with racks or misaligned drops that damage inventory.

Powered by a robust chain drive system (a hallmark of Herochu’s focus on durability), the gantry moves smoothly even under full load, with none of the slippage or inconsistency of cheaper belt-driven alternatives. It operates at a vertical lifting speed of 9m/min and an inlet/outlet speed of 12m/min—speeds that cut material transfer time by more than half compared to manual forklifts. For facilities with high-volume material flow, this translates to faster turnaround on orders and reduced bottlenecks in production.

2. Profile Material Racks: The Backbone of High-Density Storage

Gone are the days of relying on low-tier static racks that waste vertical space or floor stacking that limits accessibility. Herochu’s profile material racks are engineered as multi-tiered structures, designed to maximize storage density while supporting heavy loads. Available in standard lengths of 6015mm, 6020mm, and 6025mm (with custom lengths available for unique material sizes), these racks are built to handle 3T to 5T per layer—enough to support bundled steel pipes, thick-walled tubes, or dense bar stock.

The number of rack layers (or “floors”) is fully customizable, ranging from 8 to 13 tiers as standard (and more for facilities with higher ceilings). This vertical expansion transforms unused overhead space into valuable storage real estate. For example, a workshop with a 10-meter ceiling that previously used 2-tier static racks can now install 10-tier Herochu racks, increasing storage capacity by 400% without expanding the facility’s footprint. Each rack is constructed from high-grade steel, treated with a corrosion-resistant coating to withstand industrial wear, and tested to meet load-bearing standards—ensuring stability even when fully loaded.

3. Material Frames: Secure, Tailored Support for Every Long Good

Material frames are the unsung heroes of the system, providing specialized support for the diverse long-span goods your workshop handles. Unlike one-size-fits-all racks that force you to compromise on safety (e.g., using padding to stabilize irregularly shaped pipes), Herochu’s material frames are optionally customizable to match your inventory. Whether you’re storing thin copper pipes that need individual slots to prevent tangling, bundled steel profiles that require secure clasps, or wide flat bars that need flat, stable surfaces, we design frames to fit.

These frames are directly integrated with the gantry system, allowing for seamless lifting and transport—no need for manual intervention to reposition materials before moving them. For example, a frame designed for pipes will feature evenly spaced dividers to keep each piece separate, while a frame for bundled profiles will include adjustable straps to prevent shifting during movement. This tailored support not only protects materials from damage but also speeds up loading and unloading by eliminating the need for time-consuming adjustments.

4. Guide Rails: The Path to Smooth, Accurate Movement

Guide rails are the quiet enablers of the system’s efficiency, installed throughout the workshop to create a clear, unobstructed path for the gantry system. Made from hardened steel to resist wear (even with constant daily movement), these rails ensure the gantry travels in a straight line, maintaining precision positioning at every step. Unlike manual forklift paths— which require wide aisles and often become blocked by misplaced materials—Herochu’s guide rails are narrow and fixed, reducing the space needed for material movement. This means more room for storage racks and less wasted space on temporary paths. The rails can also be customized to fit unique workshop layouts, including curves, T-junctions, or straight runs, ensuring the system integrates seamlessly with your existing space.

Why Herochu’s Pipe Store Long Span Goods Automated Storage System Stands Above Traditional Solutions

The difference between Herochu’s system and traditional storage isn’t just automation—it’s a complete reimagining of how long-span goods should be managed. Here’s how it delivers tangible, long-term value to your workshop:

Increased Efficiency: Streamline Material Flow from Storage to Production

Manual storage systems create bottlenecks by forcing workers to spend hours locating, moving, and positioning long goods. Herochu’s automation optimizes material flow by moving goods directly to a comfortable working height for processing—eliminating the need for workers to bend, reach, or maneuver heavy equipment around cluttered racks. For example, when a production line needs a 6-meter pipe, the system automatically retrieves the pipe via the gantry, delivers it to the workstation, and updates inventory records—all without manual intervention. This streamlining cuts material handling time by up to 60%, allowing your team to focus on revenue-generating tasks instead of logistics.

Reduction of Failures: Minimize Errors and Waste

Human error—whether misplacing a pipe, miscounting inventory, or damaging materials during manual handling—costs facilities thousands of dollars annually in wasted stock and rework. Herochu’s automation minimizes these risks by replacing manual tasks with precise, repeatable processes. The system’s integrated Warehouse Management System (WMS) books stock directly when materials are stored, and even tracks shortened or cut pieces—ensuring inventory counts are always accurate. This reduces stock shortages (which delay production) and rejects (which waste materials), keeping your operations running smoothly.

Space Savings: Maximize Storage Density Without Expansion

The biggest waste in most workshops is vertical space. Traditional storage methods use only 10–20% of a facility’s available height, leaving vast areas unused. Herochu’s multi-tier racks (8–13 layers as standard) turn this wasted space into functional storage. For example, a 500-square-meter storage area with a 12-meter ceiling can use Herochu’s 10-tier racks to achieve the equivalent of 5,000 square meters of storage—enough to hold five times more pipes or profiles without expanding the facility. Additionally, the system requires less space for handling than manual forklifts or cranes, further reducing the overall footprint and freeing up room for production equipment.

Shorter Response Times: Meet Just-in-Time Production Needs

In today’s fast-paced industrial environment, production lines often rely on just-in-time (JIT) material delivery to avoid excess inventory and reduce costs. Manual storage systems struggle to keep up with JIT demands, as retrieving a specific pipe or profile can take 15–30 minutes. Herochu’s automated system delivers long goods in minutes: a quick input into the WMS triggers the gantry to retrieve the material and deliver it to the production line—ensuring your team never waits for the materials they need. This is especially critical for facilities with continuous production cycles, where delays in material delivery can shut down entire lines.

Improved Stock Management: Real-Time Visibility for Better Control

Keeping track of long-span goods—especially when stored in large quantities or varying lengths—can be a logistical nightmare with manual systems. Herochu’s system includes a WMS that provides real-time monitoring and tracking of inventory. You can see exactly how many pipes of each length are in stock, where they’re stored, and when they were last accessed—all from a user-friendly dashboard. This visibility allows for better stock control: you can reorder materials before shortages occur, identify slow-moving inventory to adjust purchasing, and even track material usage to optimize production plans.

Work Safety: Protect Your Team from Injury

Manual handling of long, heavy goods—whether lifting pipes with a crane or moving bundles with a forklift—increases the risk of workplace injuries, including back strains, crushed fingers, and falls. Herochu’s automation reduces or eliminates these risks by taking over manual handling tasks. The gantry system lifts and transports heavy loads, and the WMS minimizes the need for workers to enter storage areas—keeping your team out of harm’s way. This not only protects your employees but also reduces workers’ compensation claims and downtime related to injuries.

Flexibility: Adapt to Changing Production Needs

Workshops don’t stay static—material volumes grow, new product lines require different pipe or profile sizes, and facility layouts evolve. Herochu’s system is designed to adapt: its modular components (guide rails, material frames, and even gantry extensions) can be easily reconfigured or expanded to meet changing needs. For example, if you start storing longer 8-meter pipes, you can extend the material frames and adjust the rack lengths without replacing the entire system. If your workshop expands, you can add new guide rails and racks to integrate with the existing setup. This flexibility ensures your investment grows with your business, avoiding the “rip and replace” cycle of rigid storage solutions.

Data Management & Analysis: Optimize Operations with Actionable Insights

Automated systems generate valuable data on warehouse activities—from how often certain materials are accessed to how long retrieval takes—which manual systems can’t capture. Herochu’s system collects this data and presents it in easy-to-analyze reports, allowing you to identify inefficiencies (e.g., a slow retrieval process for a specific pipe type) and optimize workflows. You can also use this data to predict future demand: for example, if data shows you use 100 6-meter pipes per month, you can schedule reorders to avoid stockouts. This data-driven approach turns your storage system into a tool for continuous improvement.

Reduced Costs: Lower Total Cost of Ownership

While the initial investment in an automated system is higher than manual alternatives, the total cost of ownership (TCO) is significantly lower over time. Herochu’s system reduces costs in three key ways: it increases efficiency (cutting labor hours spent on material handling), reduces waste (minimizing damaged or lost inventory), and lowers labor needs (reducing the number of workers required for storage tasks). Many facilities find that the system pays for itself within 2–3 years through these cost savings—making it a smart long-term investment.

Effective Staff Deployment: Maximize Skilled Labor

Manually moving and handling long goods ties up skilled workers in repetitive, low-value tasks—tasks that could be better spent on specialized work like fabrication or quality control. Herochu’s automation frees up your team: instead of operating forklifts or searching for materials, skilled workers can focus on tasks that require their expertise. This not only improves job satisfaction but also addresses the industry-wide shortage of skilled labor by making the most of the talent you already have.

Herochu’s Specifications: Built to Fit Your Workshop

While every Herochu Pipe Store Long Span Goods Automated Storage System is customizable, our standard configurations are designed to meet the needs of most industrial facilities. Below is a breakdown of key specifications to help you start planning:

|

Specification Category

|

Standard Details

|

Customization Options

|

|

Material Length Support

|

6015mm, 6020mm, 6025mm

|

Any length (e.g., 4000mm, 8000mm) to match your pipe or profile sizes

|

|

Number of Floors (Rack Tiers)

|

8–13

|

5–20+ tiers (based on ceiling height and load requirements)

|

|

Load per Layer

|

3T, 5T

|

Up to 10T per layer (for heavy-duty applications like thick-walled steel pipes)

|

|

Mode of Movement

|

Linear guide rail + chain

|

Custom rail paths (curves, T-junctions, etc.) for unique facility layouts

|

|

Transmission Mode

|

Chain drive

|

High-torque chain drives for extra-heavy loads (optional)

|

|

Vertical Lifting Speed

|

9m/min

|

Adjustable speed (5–12m/min) for fragile materials

|

|

Inlet/Outlet Speed

|

12m/min

|

Adjustable speed (8–15m/min) for high-volume operations

|

|

Profile Support

|

Optional, customizable frames

|

Frames for pipes, bars, profiles, or irregularly shaped long goods

|

Every system also includes a user-friendly PLC control panel with a touchscreen interface, allowing operators to monitor operations, schedule material retrievals, and troubleshoot issues. For advanced integration, the system is compatible with most ERP and production management software, letting you sync storage data with your overall operational workflow.

Why Choose Herochu? More Than a System—A Long-Term Partner

At Herochu, we don’t just sell storage systems—we build solutions that grow with your business. Our commitment to quality is reflected in every component: from the corrosion-resistant steel of the racks to the precision-engineered chain drives of the gantry. Every system undergoes rigorous testing before shipment, ensuring it meets CE, EU, and ISO 9001 standards, and we back our products with a 5-year warranty on structural components and a 2-year warranty on electrical and moving parts.

But our support doesn’t end at installation. Our team provides on-site training for your operators, ensuring they can use the system safely and efficiently. We also offer 24/7 technical support—whether you have a question about adjusting the gantry speed or need emergency troubleshooting, our experts are just a call away. And as your business evolves, we’re here to reconfigure, expand, or upgrade your system, ensuring it always meets your changing needs.

Get Started with Herochu Today

If you’re tired of wasted space, slow material retrieval, human error, and safety risks, Herochu’s Pipe Store Long Span Goods Automated Storage System is the solution. Starting at $42,000, it’s an investment that delivers immediate efficiency gains and long-term cost savings—transforming your storage from a bottleneck into a competitive advantage.

Contact our sales team today for a free, no-obligation assessment of your workshop. We’ll evaluate your material types, storage needs, and facility layout, then design a custom system that fits your budget and workflow. With Herochu, you’re not just buying a storage system—you’re taking the first step toward a more efficient, safe, and profitable operation.

Herochu Pipe Store Long Span Goods Automated Storage System: Engineered for Long Materials. Built for Your Success.

Q1: What steps should I take to start the procurement process?

You may get in touch with our backend technical staff first. Based on your specific parameters, we will formulate a suitable technical solution and provide a quotation. Alternatively, you can leave your contact details—such as WhatsApp, WeChat, or email address—and our professional sales team will reach out to you proactively.

Q2: How can I inform you of my need for suitable shelves?

You can share key information with us, including the type of items you plan to store on the shelves, the dimensions of those items, the quantity of shelves required, and any other specific details you have. With this information, we will develop a professional solution tailored to your needs. If you prefer, you can also leave your contact information, and our specialized team will contact you to address your questions.

Q3: Should I choose a loading robotic arm or an integrated loading and unloading system?

To determine the right option, two key factors need to be considered first:

- The table size of your laser cutting machine must meet the matching requirements for the equipment.

- We need to know your specific loading method—whether it is a board rack, exchange platform, or material warehouse.

For a more accurate recommendation based on your specific needs, please leave your contact information, and we will provide targeted service.

Q4: Do you offer on-site installation and debugging services?

Yes, we do. We can dispatch professional technicians to your factory to carry out on-site installation and debugging of the robotic arm, and we will continue working until the equipment completes a successful trial operation. Our team has provided such services in many countries, including South Africa, the United States, Russia, South Korea, Qatar, Egypt, Lebanon, and Mexico.

Q5: What measures do you take to ensure product quality?

We have a comprehensive quality assurance system, supported by the following key measures:

- A team of over 40 technical engineers, with professional mechanical engineers responsible for debugging equipment and resolving any technical concerns.

- A dedicated quality inspection department that strictly adheres to ISO9001 quality standards, ensuring all products meet the required quality specifications.

- Professional CE certification, which guarantees smooth export procedures for our products to global markets.

- Mandatory load testing for all equipment before shipment, ensuring the structural safety and operational stability of each product.

Q6: Where is your factory situated?

Our factory is located in Jinan, Shandong Province, China, specifically at No. 10 Industrial Park, Jiyang Street. It features a modern, standard workshop covering an area of 10,000 square meters.

Q7: How can I verify your company’s strength?

We offer two convenient ways for you to assess our company’s capabilities:

- We can arrange a video tour of our factory, allowing you to remotely view our production environment and facilities.

- We warmly welcome you to visit our factory in person for an on-site inspection.

Q8: What type of company are you?

We are Jinan Constant Storage Machinery Manufacturing Co., Ltd., a high-tech enterprise that integrates research and development, production, sales, installation, and after-sales service. Our core product range includes intelligent sheet metal material warehouses, drawer-type sheet metal shelves, telescopic cantilever shelves, servo swing arm manipulators, gantry loading and unloading manipulators, fully automatic loading and unloading systems, and heavy-duty sheet metal and pipe storage shelves. Equipped with a professional technical team and advanced production equipment, we are committed to providing high-quality, high-performance mechanical products and customized solutions to customers around the world.

PRODUCTS

-

Heavy Duty Cantilever Racking System

Heavy Duty Telescopic Cantilever Storage System Metal Pipe Storage System Shelves

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Automatic Steel Plate Storage Racking System

Read moreRated 0 out of 5 -

Automated Sheet Metal Storage Systems

Automatic Pallet Racking System Solution Steel Shelf Metal Rack

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Pipe Store Long Span Goods Automated Storage System

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Manual Control Roll out Sheet Metal Rack with Forklift

Read moreRated 0 out of 5 -

Sheet Metal Storage Racks

Pull Out Sheet Storage Drawer Rack Roll-Out Sheet Rack for Sheets

Read moreRated 0 out of 5 -

Heavy Duty Cantilever Racking System

Customizable Workshop Storage Cantilever Racking System

Read moreRated 0 out of 5